Conductive heating ceramic tube and preparation method

A technology of conductive heating and ceramic tubes, applied in the direction of heating element shape, etc., can solve the problems of poor safety, difficult maintenance, waste of energy, etc., and achieve the effects of low cost and transformation cost, good waterproof and insulating performance, and high electrothermal conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

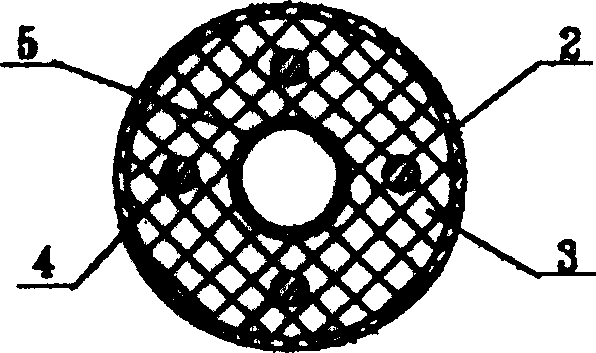

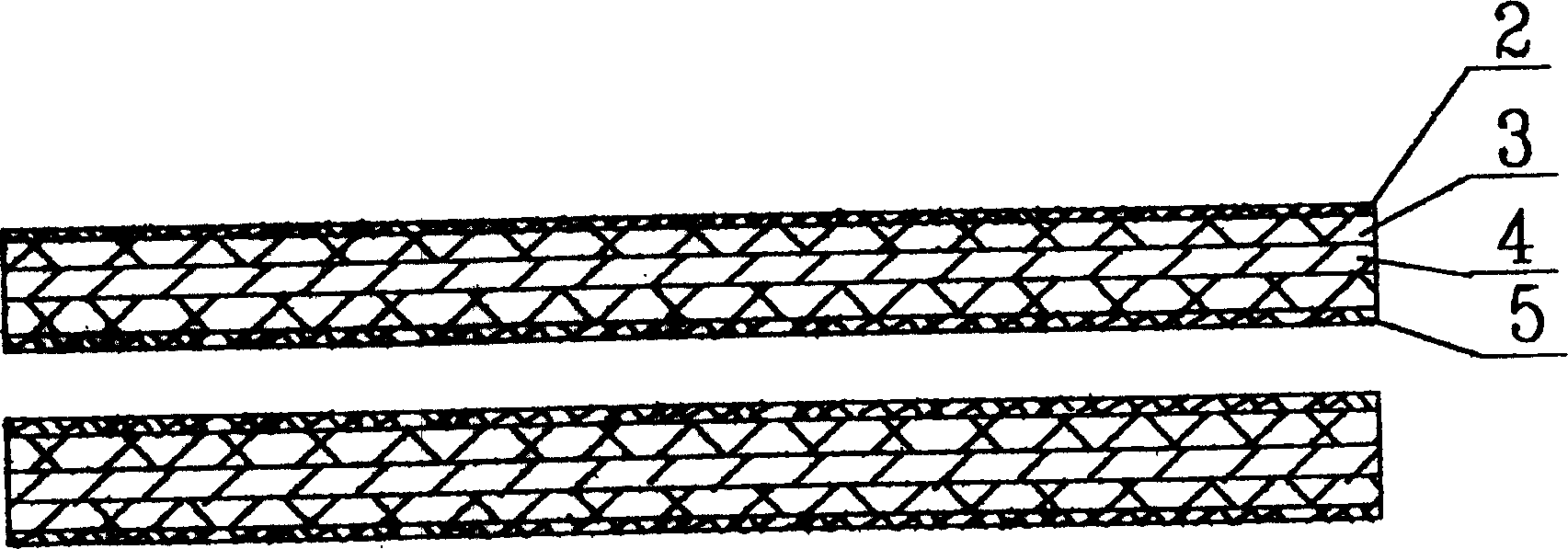

[0033] According to the proportion of ceramic raw materials (clay) accounting for 90% of the weight of the mixture, conductive filler particles with a particle size of 5μ-10μ accounting for 10% of the weight of the mixture, the mixture is composed, and the traditional manufacturing methods such as mixing, ball milling, granulation, molding, sintering, and glazing are used. The outer surface is insulated, and the ceramic tube with conductive strips embedded in the middle is made by pottery technology.

Embodiment 2

[0035] The mixture is composed of clay accounting for 50% of the weight of the mixture and conductive filler particles with a particle size of 50μ accounting for 50% of the weight of the mixture. After a traditional sintering process, a ceramic tube with an insulating outer surface and a conductive strip embedded in the middle is prepared.

Embodiment 3

[0037] The mixture is composed of clay accounting for 75% of the weight of the mixture, and conductive filler particles with a particle size of 30μ accounting for 25% of the weight of the mixture. After a traditional sintering process, a ceramic tube with an insulating outer surface and a conductive strip embedded in the middle is prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com