Wiper blade for vehicle

A wiper, wiper arm technology, used in vehicle maintenance, vehicle cleaning, transportation and packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

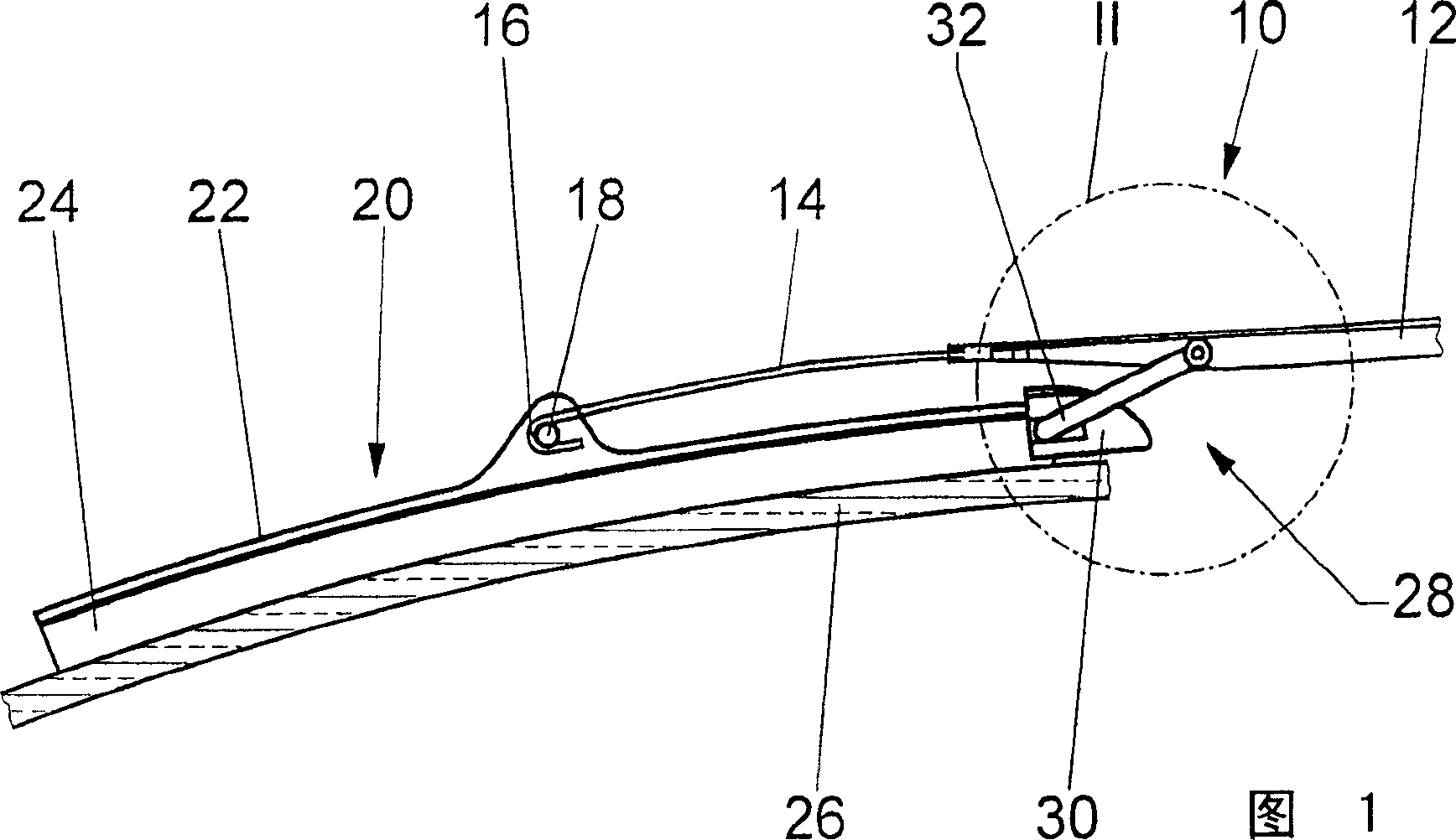

[0029] 1 shows a hinge 12 of a wiper arm 10 and a wiper rod 14, the hook-shaped end 16 of the wiper rod surrounds the hinge pin 18 of a wiper blade 20 and thus makes the wiper blade 20 It is hingedly connected with the wiper arm 10. The wiper blade 20 has a wiper strip strut 22 and a wiper strip 24 . This wiper strip bears against the window pane 26 .

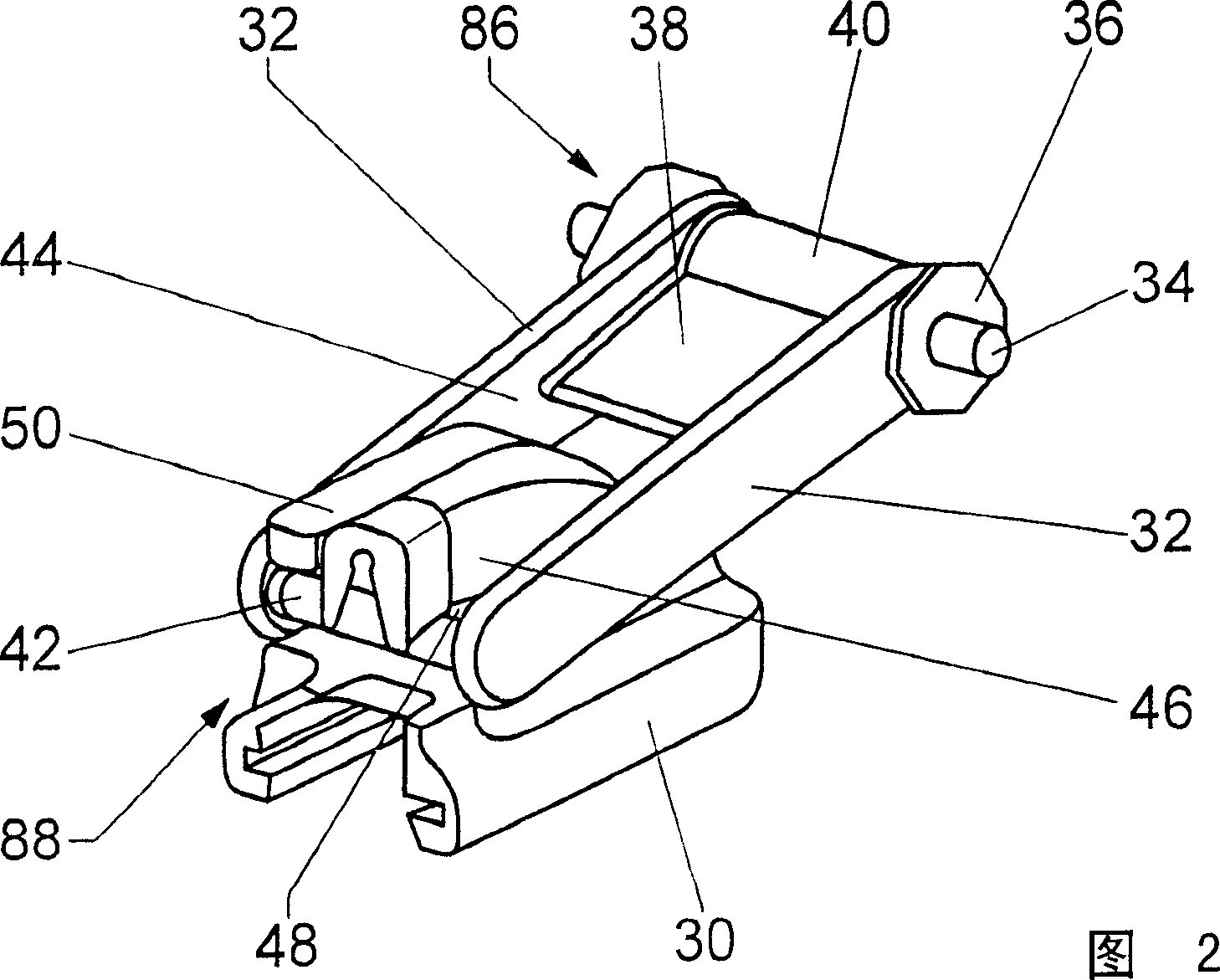

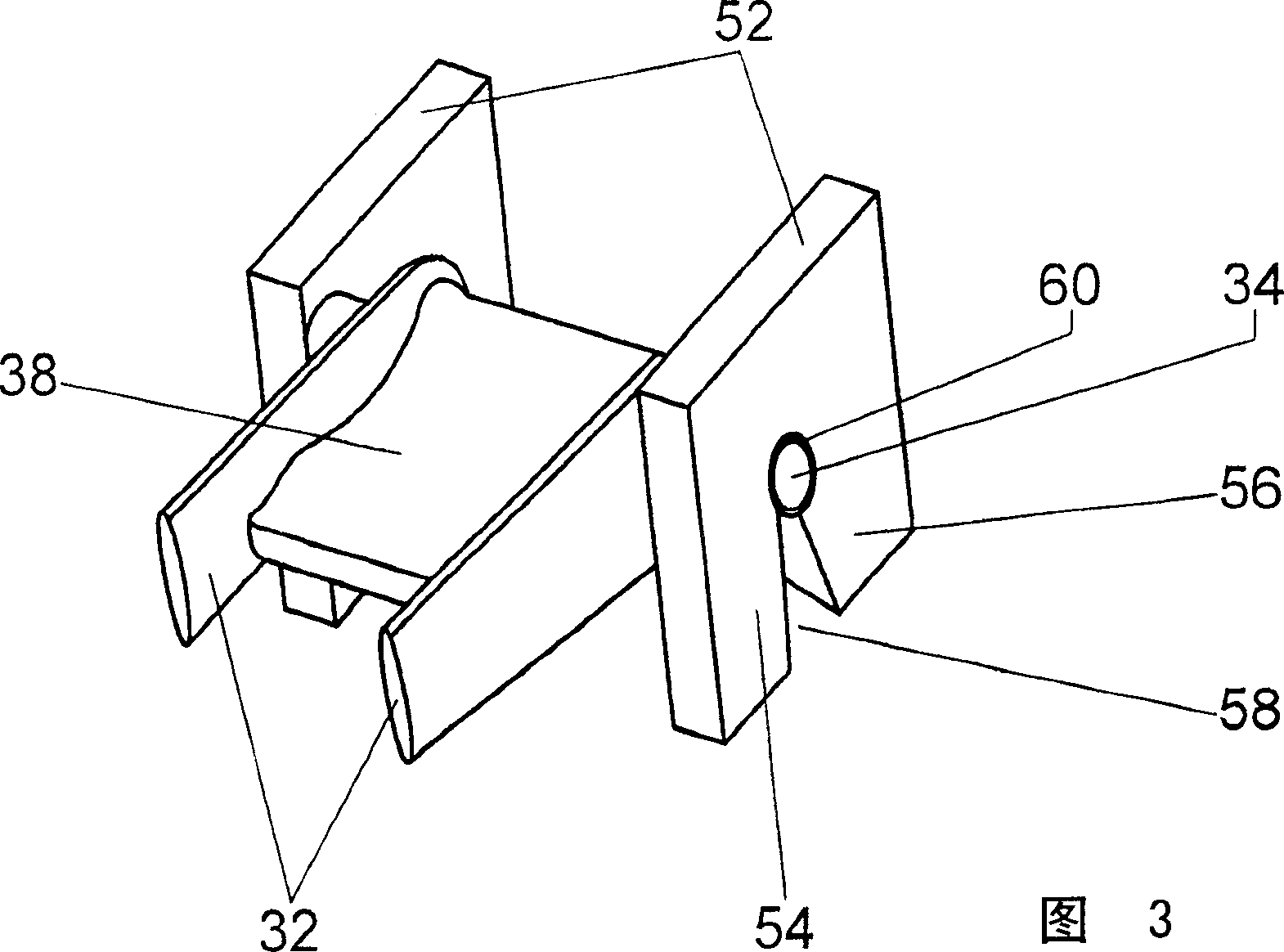

[0030] Between the wiper blade 20 and the joint 12 of the wiper arm 10 there is a device 28 ( FIG. 2 ) for laterally guiding the wiper blade 20 with two connecting rods 32 arranged in parallel. The connecting rod 32 is rotatably mounted at its ends in swivel bearings 86 and 88 . On the side of the wiper arm 10 , the pivot bearing 86 has a pivot shaft 34 which is fixedly connected to the connecting rod 32 and consists of two lateral pins. The axis of rotation 34 can also pass integrally through the sleeve part 40 of the device 28 . It is either fixedly connected to the connecting rod 32 and the sleeve part 40 and is pivotabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com