Sleeve screw propeller thrustor

A sleeve screw and propeller technology, applied in ship propulsion, propulsion parts, ship parts, etc., can solve the problems of inability to quickly flush, waste power, and inability to rotate, prolong service life, reduce maintenance and cleaning, The effect of promoting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below in conjunction with accompanying drawing, the present invention is described in further detail with preferred embodiment:

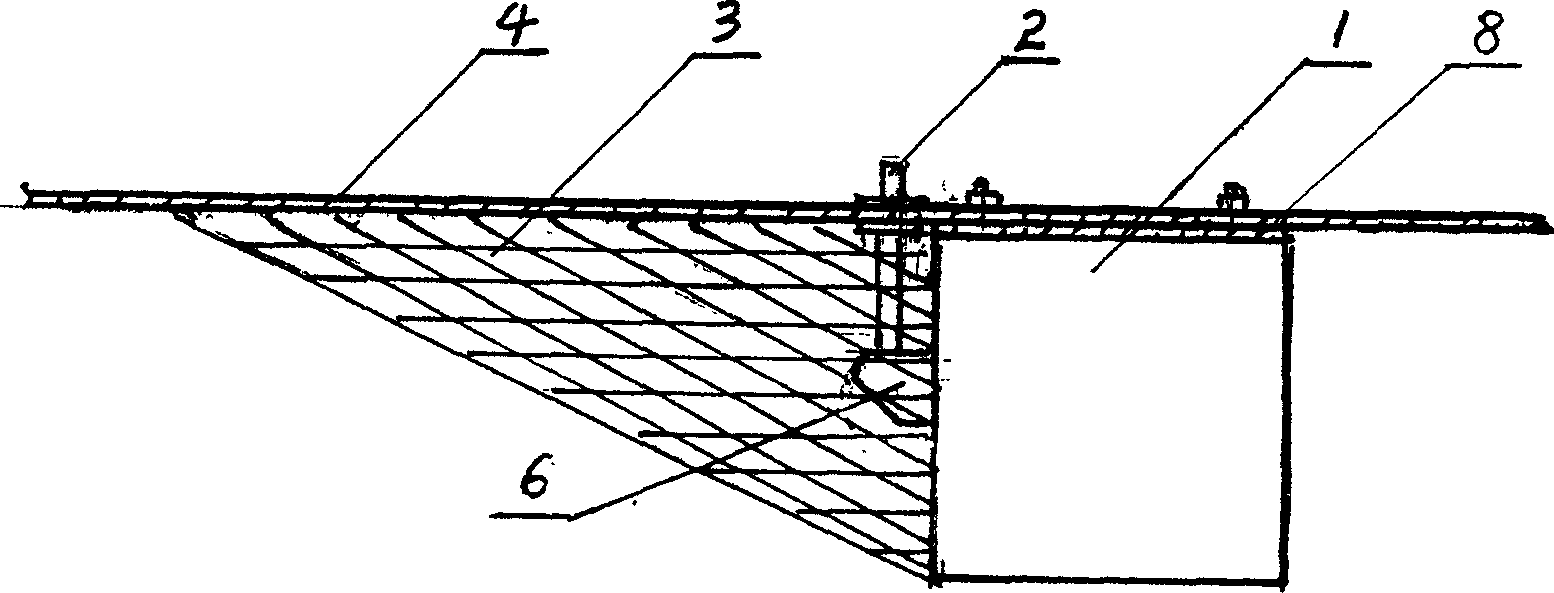

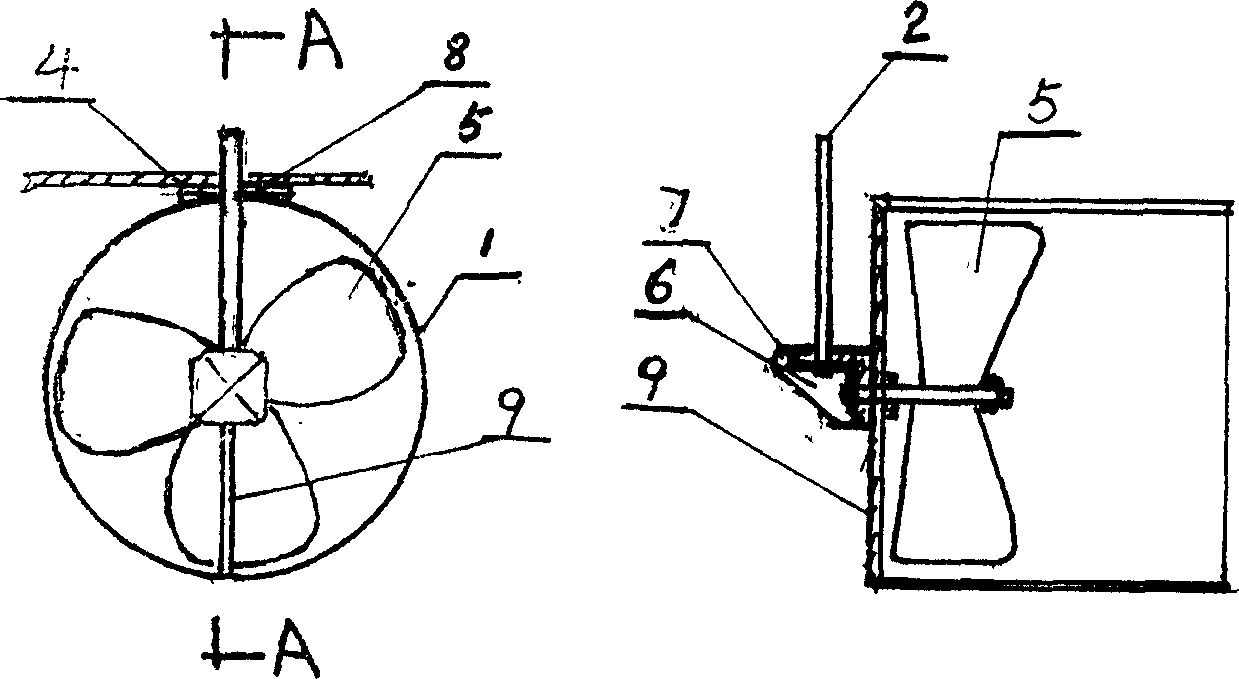

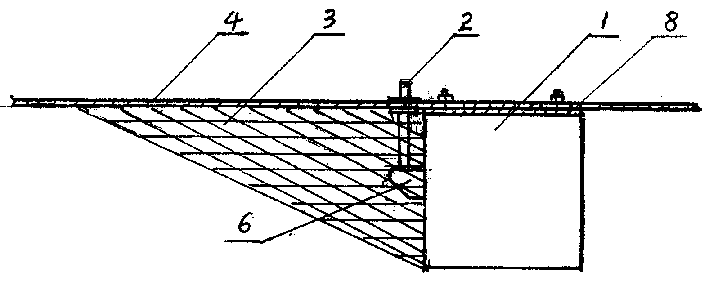

[0010] The present invention consists of propeller, enclosure sleeve (1) and protective fence (3). The enclosure sleeve (1) has the same length as the diameter of the propeller and the same front and rear caliber. The top of the enclosure sleeve (1) is fixed on the On the bottom plate of the hull (4), the fixed sleeve connecting rod (9) connects the rotating shaft part of the center of the propeller with the enclosure sleeve (1), and the connecting part of the propeller rotating shaft and the fixed sleeve connecting rod (9) A power steering box (6) is provided, and the upper end of the power rotating shaft (2) is fixed on the bottom plate (4) of the hull, and the lower end thereof is driven by the power steering gear (7) in the power steering box (6). , to drive the propeller blades (5) to rotate, and the protective fence (3) is arranged betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com