Laser aligner for realizing self collimator quick capturing and alignment method

An autocollimator and laser technology, which is applied in the fields of instruments, optics, optical components, etc., can solve the problems of non-professionals spending a lot of time, difficulty in finding work, and small autocollimators, so as to improve the use efficiency and application. Scope, find the method quickly, use the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

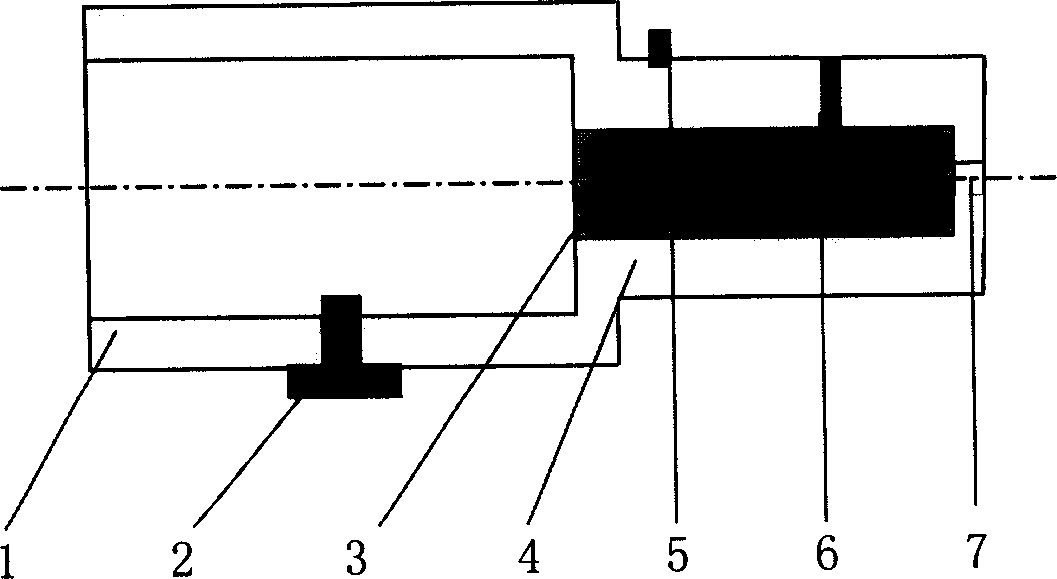

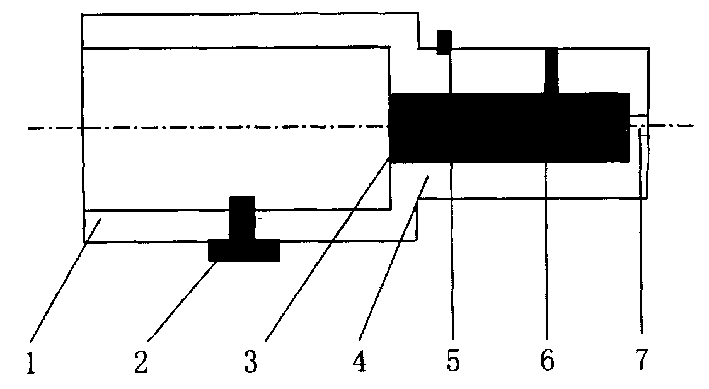

[0013] As shown in the figure, the laser aligner is mainly composed of autocollimator positioning sleeve, locking screw, semiconductor laser, fine-tuning screw, micro switch and other parts. The positioning sleeve is directly sleeved on the objective lens tube of the autocollimator in a sliding manner, and the screw is fixed to fix it. The semiconductor laser is composed of a semiconductor laser diode, an optical system, a button battery and a corresponding mechanical structure. The switch is installed on the laser sleeve, and a small hole with a diameter of 1 to 3 mm is opened on the front sleeve of the laser. When assembling, adjust the fine-tuning screw to make the optical axis of the laser coincide with the axis of the sleeve and the exit hole.

[0014] Turn on the micro switch of the laser, and the red laser emitted by the semiconductor laser emits red light through the exit hole with a diameter of 1-3 mm at the front of the sleeve. hole. In this way, it is ensured that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com