Screw groove non-contact leak-less mechanical seal system for centrifugal pump

A technology of mechanical seals and mechanical seal devices, applied to mechanical equipment, pumps, pump components, etc., can solve problems such as sealing function failure and leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

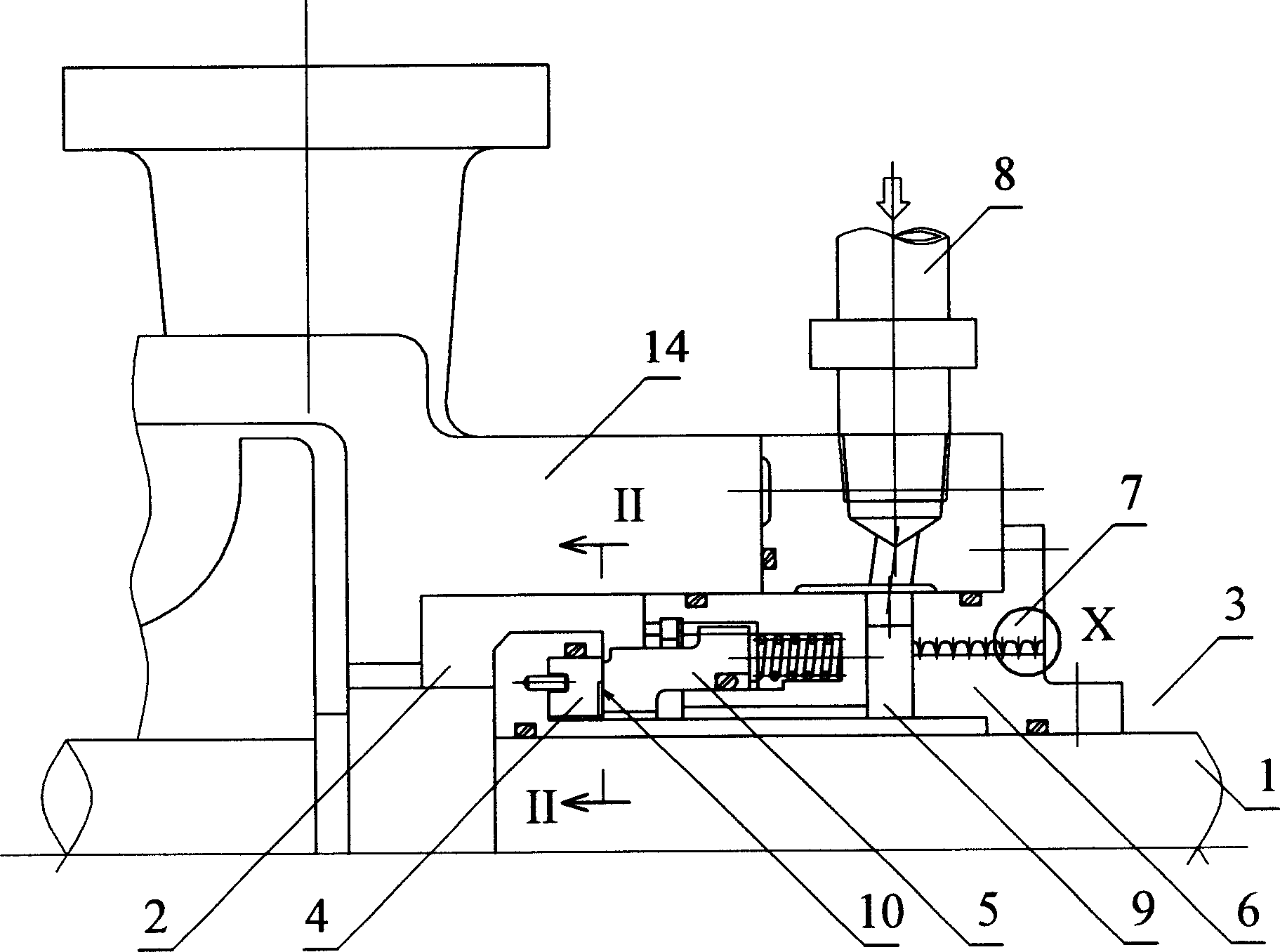

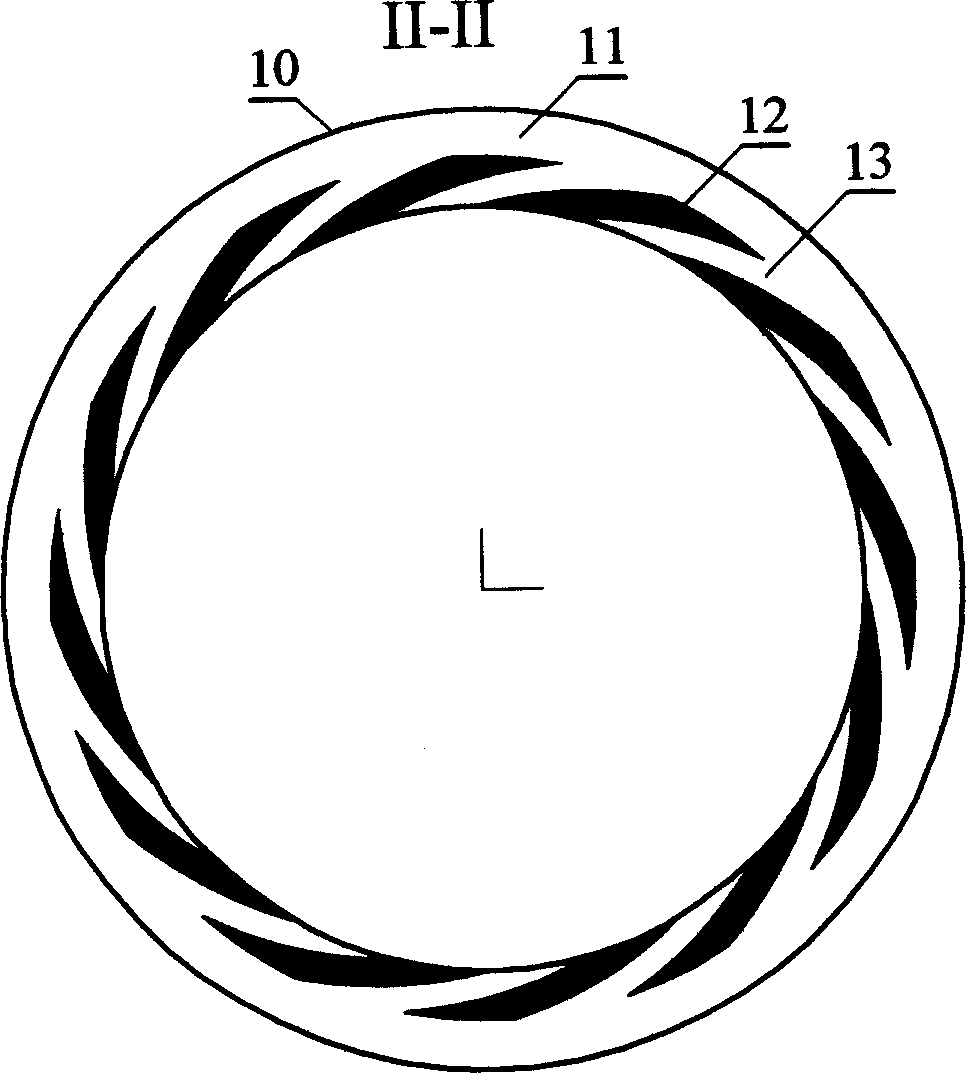

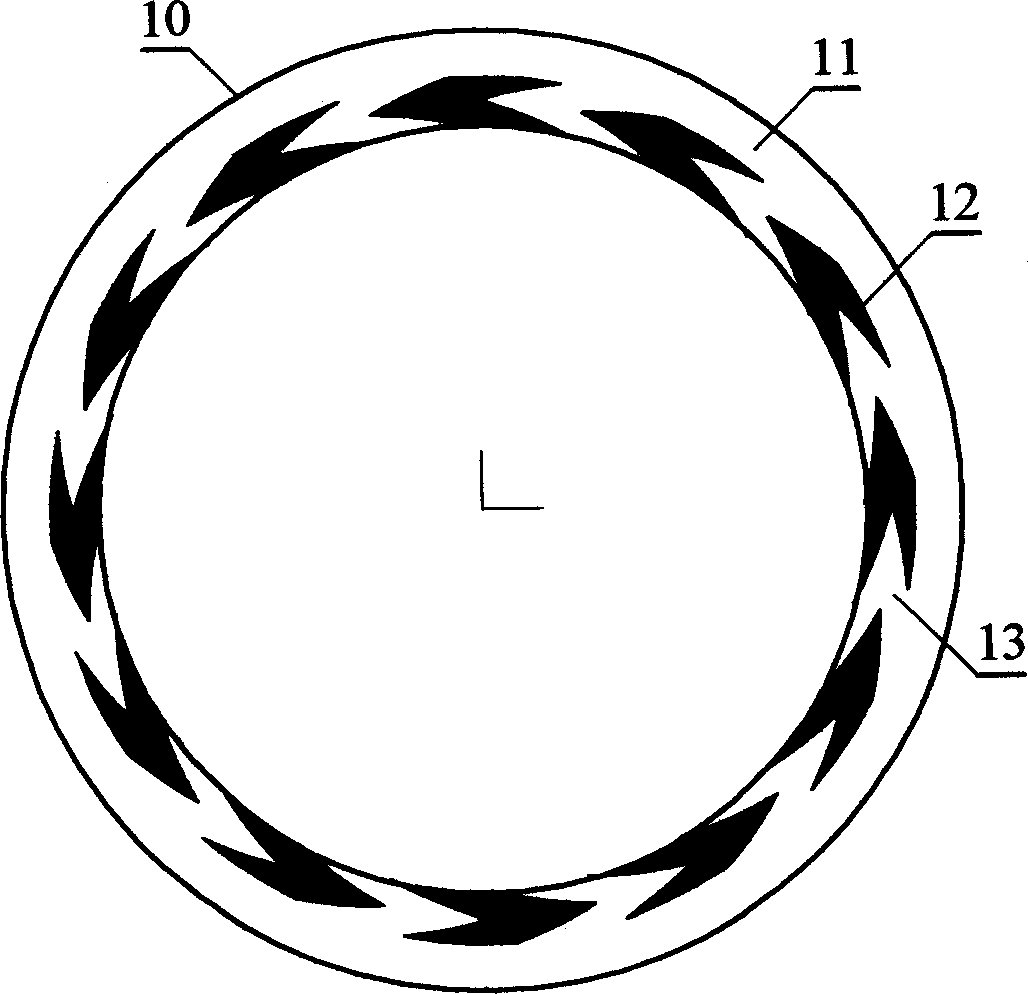

[0015] The spiral groove non-contact non-leakage mechanical seal system for centrifugal pumps is composed of non-contact non-leakage mechanical seals, non-contact auxiliary shaft seals, buffer fluid support systems, pump shafts and pump bodies. The rotating ring 4 of the sealing device is installed on the rotating shaft 1 of the centrifugal pump, and the floating ring 5 of the mechanical sealing device of the spiral groove non-contact reverse flow pump is installed on the pump body 14 (see figure 1 ) to form a non-contact and leak-free mechanical seal system; the seal chamber 9 provides a buffer fluid with a pressure lower than the negative leakage of the pump working chamber 2 through the seal support system 8 (such as oil, water and other neutral media, which must be mixed with the pump process medium In addition, a screw pump cylindrical surface non-contact auxiliary seal is installed on the outside, the rotating part 6 is installed on the pump shaft 1, and the stationary pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com