Ranitidine hydrochloride capsule producing process

A technology of ranitidine hydrochloride and production process, which is applied in the field of production technology of ranitidine hydrochloride capsules, can solve the problems of slow dissolution, influence on drug absorption, influence on drug efficacy and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

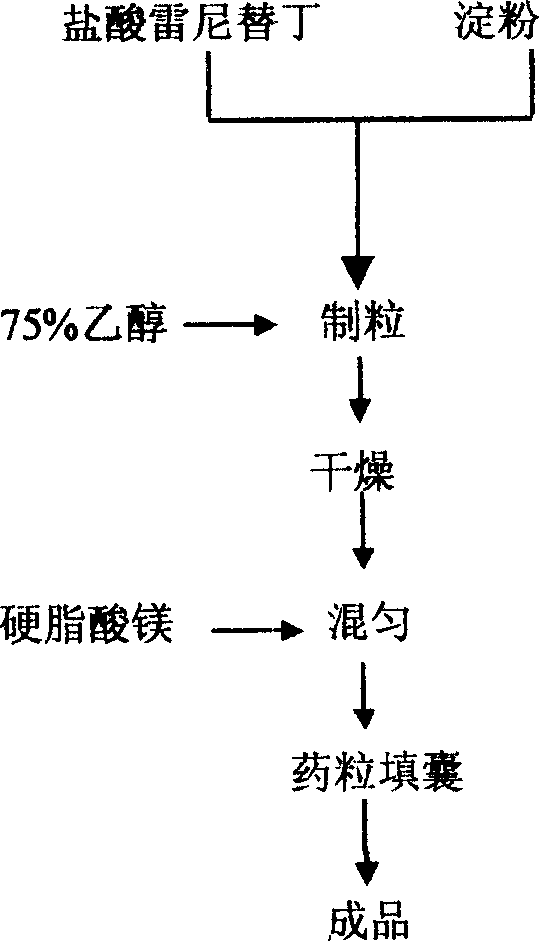

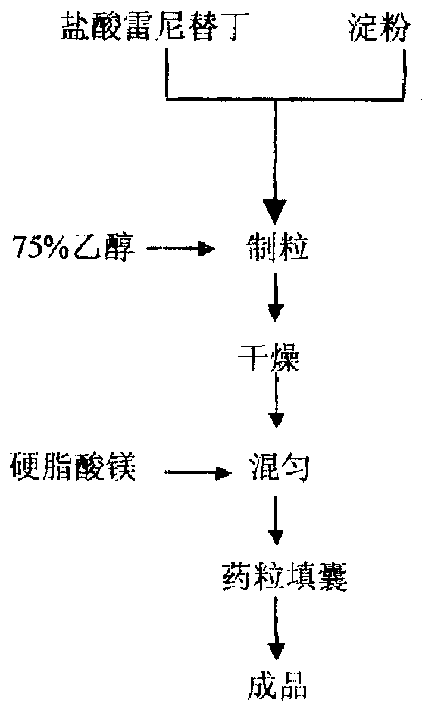

[0010] see figure 1 , the prescription of the present embodiment production technology is:

[0011] Name of raw and auxiliary materials Sieve size (mm / mesh) Consumption per 10,000 grains (kg)

[0012] Ranitidine hydrochloride 1.3 / 14 1.70

[0013] Starch 0.30 / 60 0.87

[0014] 75% ethanol filter 0.172

[0015] Magnesium stearate 0.44 / 40 0.02056

[0016] Process specification

[0017] 1. Processing of raw and auxiliary materials:

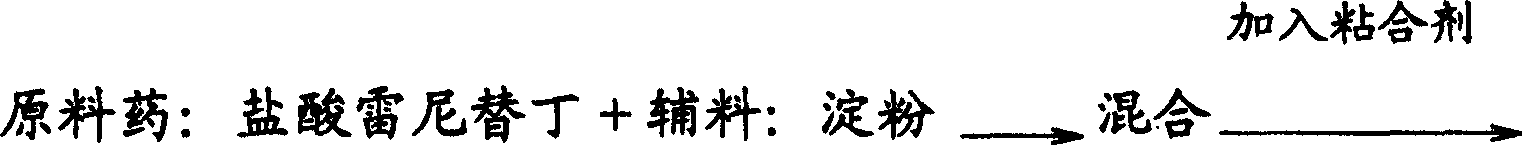

[0018] 1. Raw materials of ranitidine hydrochloride are processed through a 14-mesh sieve and set aside. The starch is processed through a 60-mesh sieve and set aside. Magnesium stearate is processed through a 40-mesh sieve for subsequent use.

[0019] 2. Weigh ethanol and add the calculated amount of deionized water to make a 75% ethanol solution for later use.

[0020] 2. Granulation:

[0021] 1. Weigh the prescribed amount of ranitidine hydrochloride and starch, alternately put them into the batching pot of the wet mixing granulator, close...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com