Prefabricated regenerated stone block for rockery, its fabrication process, regenerated stone rockery and its piling up method

A technology of remaking stone and prefabricated sheets, which can be used in decorative art, imitation of three-dimensional effect patterns, and techniques for producing decorative surface effects, etc., and can solve problems such as reengineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

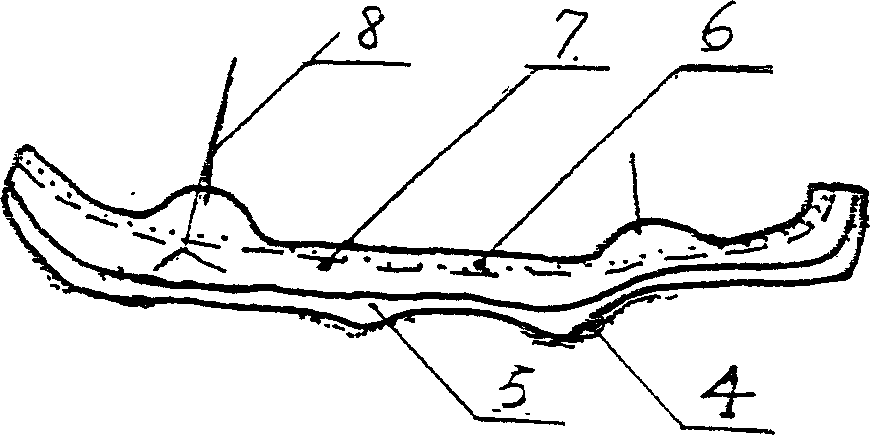

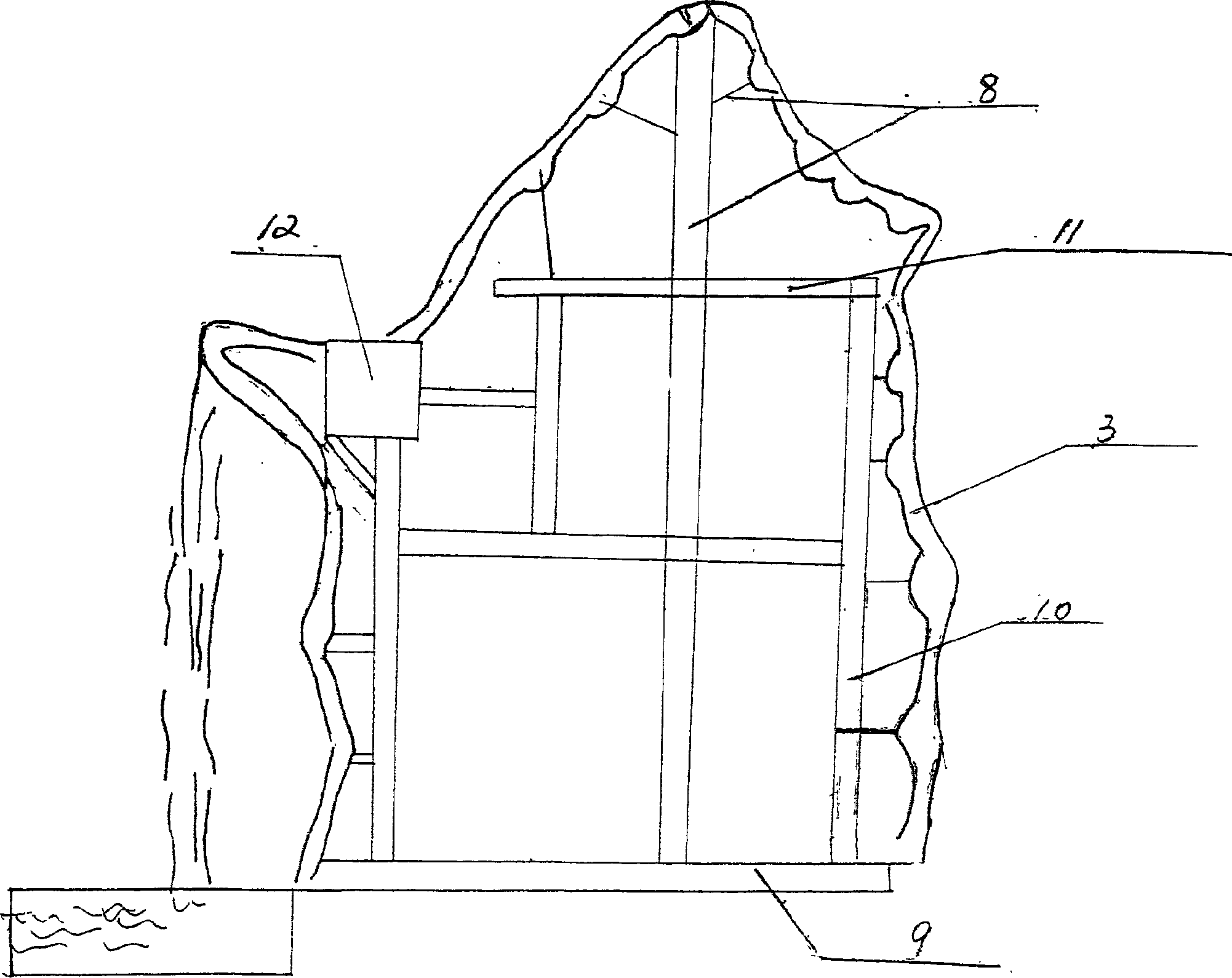

[0070] figure 1 It is a structural drawing of a prefabricated piece of rebuilt rockery, which includes: an outer mold layer 1, an inner mold layer 2, and a rockery piece 3. figure 2 It is a structural diagram of the rebuilt rockery piece, which includes a mountain shadow layer 4, a decorative layer 5 and a structural layer 6, wherein the structural layer includes an alkali-resistant fiber mesh 7 and a support frame 8;

[0071] In the process of making rockery pieces, the rockery preforms are made first, and then the rockery preforms are demolded to produce rockery pieces 3. The production process of the rockery prefabricated film includes mold making, mountain shadow painting, decorative layer spraying, structural filling and cleaning. They are:

[0072] A. The molding process of the prefabricated rockery:

[0073] (1) Clean the master mold, dry it, and apply alkaline soapy water on the master mold; the master mold is an entity with a certain shape and structure;

[0074] (2) U...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com