Ultra-thin type centreless motor

An ultra-thin, wire-wound technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems that the rotor cannot be thin and the starting voltage is large

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] Specific implementation

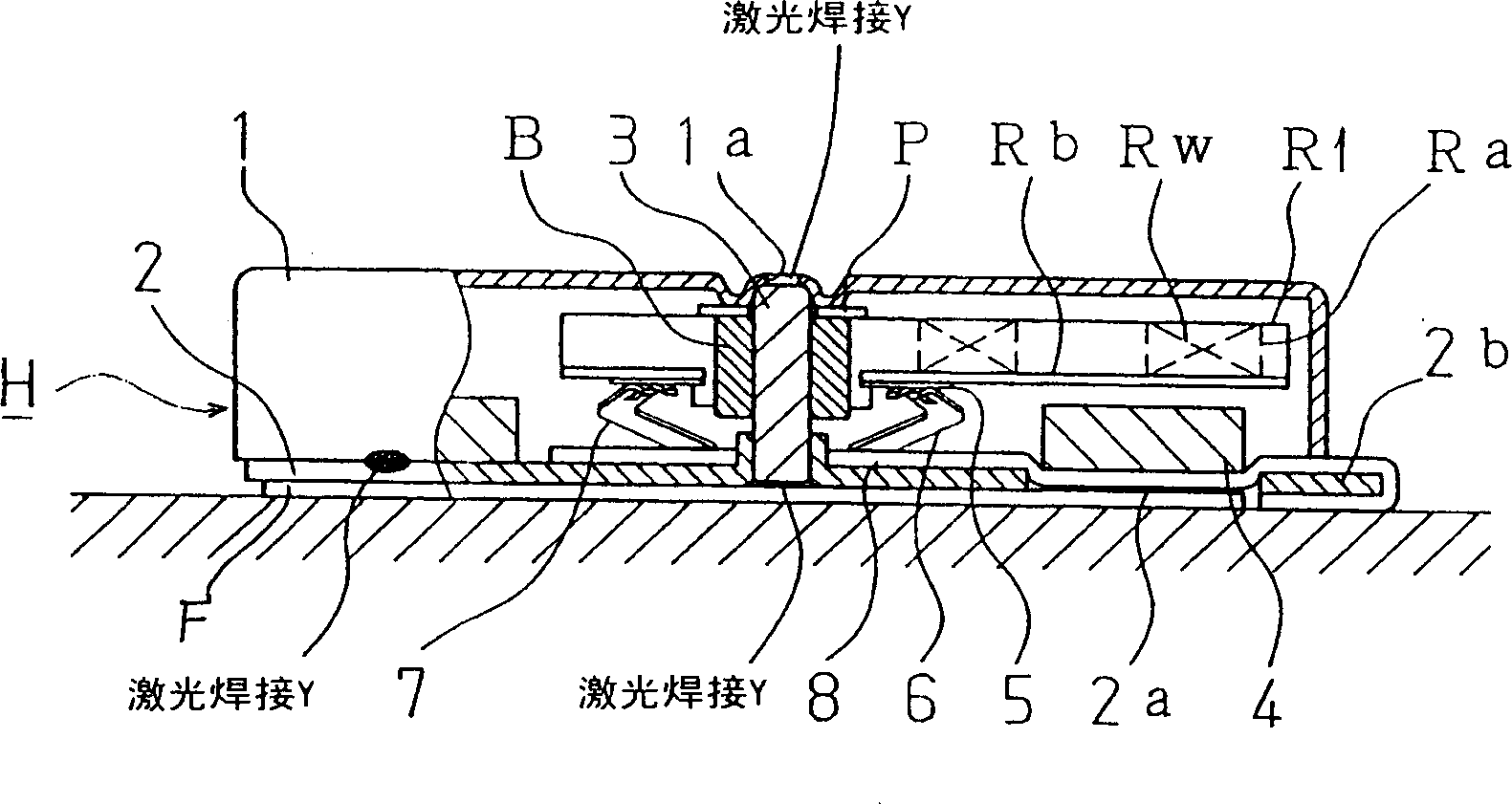

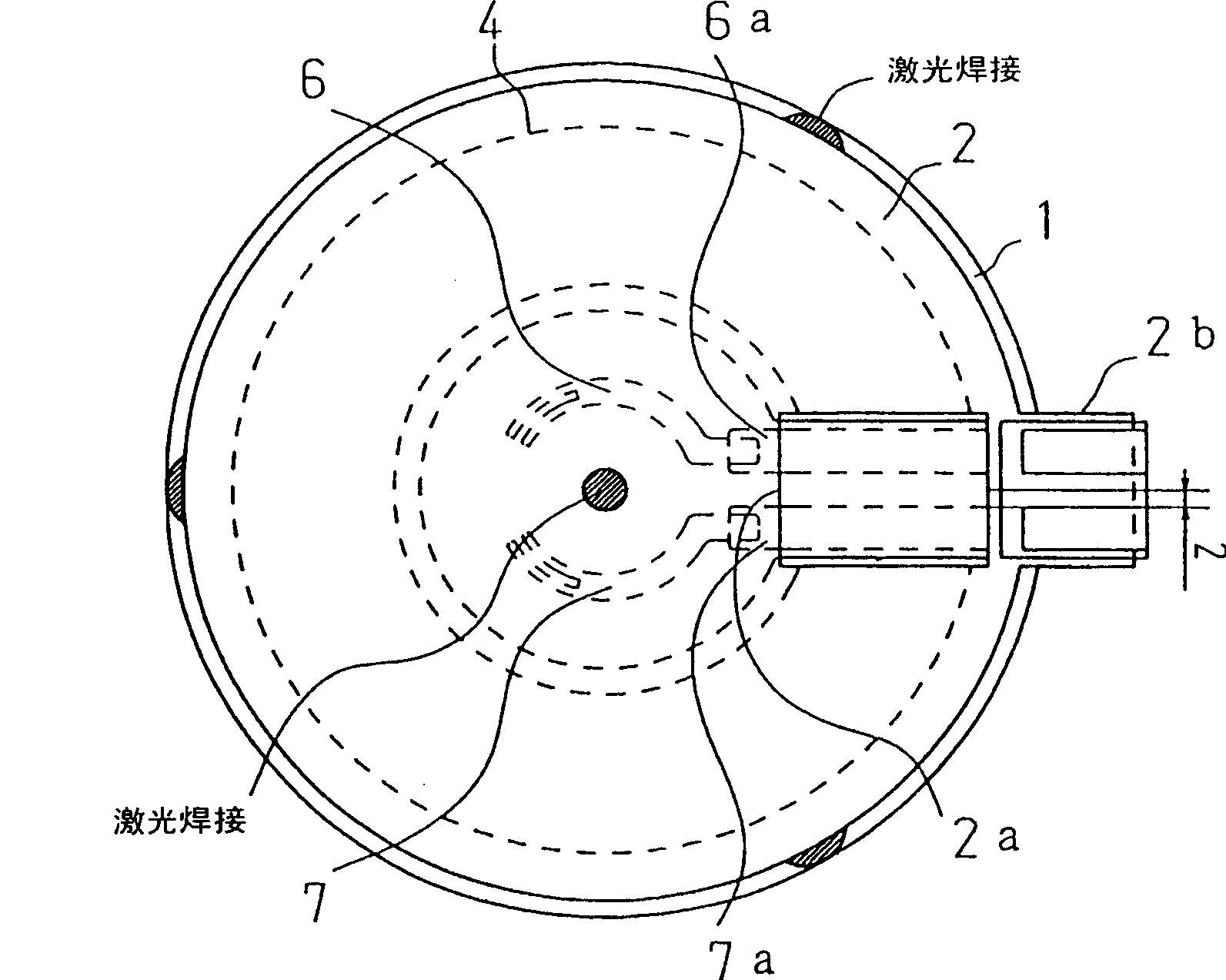

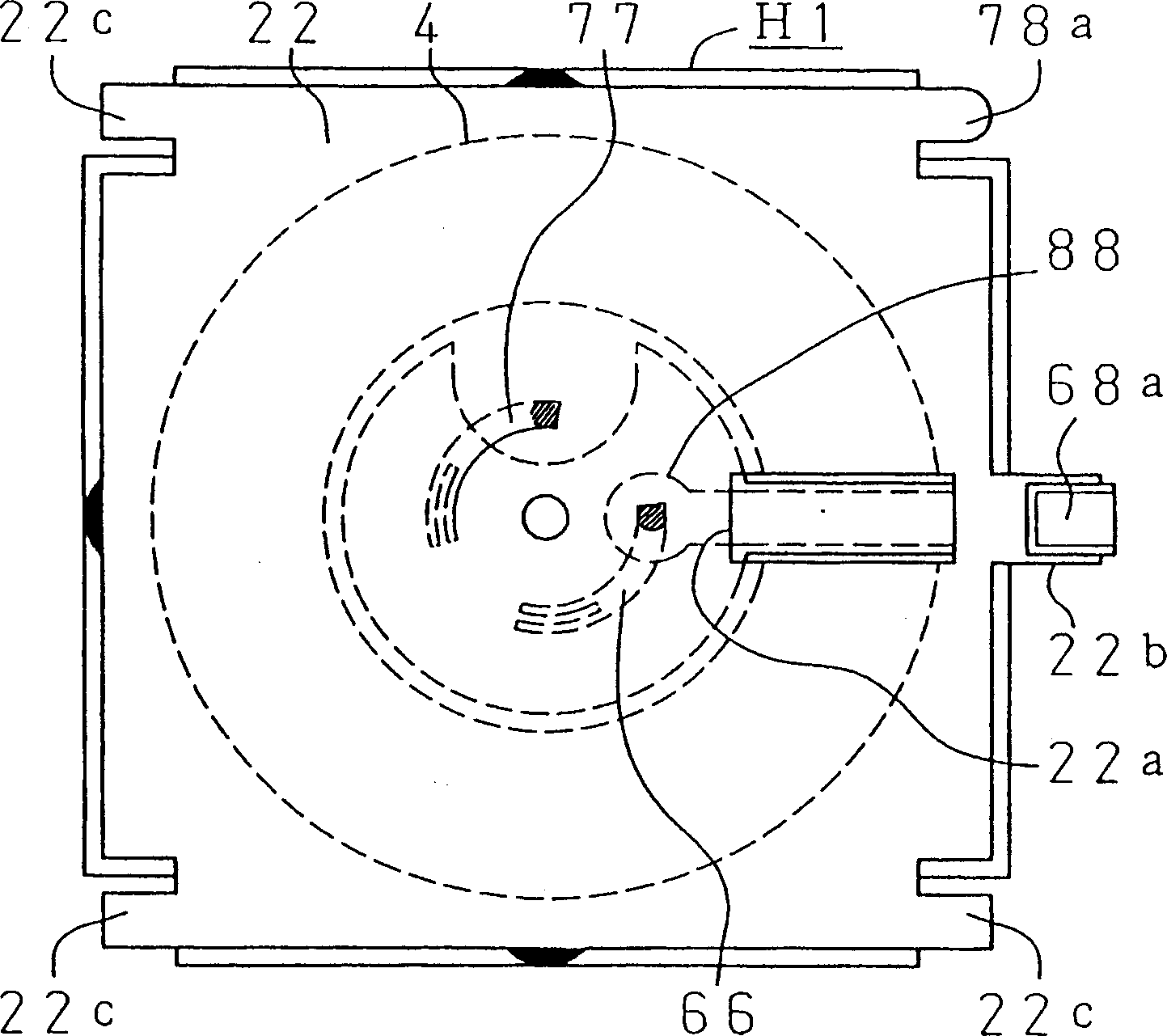

[0063] figure 1 It is a cross-sectional view of the ultra-thin coreless vibration motor as the first embodiment of the present invention. figure 2 To show figure 1 The bottom view of the characteristics of the power supply structure. image 3 for figure 1 Bottom view of a modification of the power supply structure. Figure 4 for figure 1 The top view of the eccentric rotor. Figure 5 It is a top view of a modified example of the same rotor. Figure 6 This is a cross-sectional view of an ultra-thin coreless vibration motor according to the second embodiment of the present invention. Figure 7 shows Figure 6 The bottom view of the characteristics of the power supply structure. Figure 8 for Figure 6 The top view of the eccentric rotor. Picture 9 for Figure 6 An explanatory diagram of the principle of rotation of the motor. Picture 10 It is a top view of another embodiment of an eccentric rotor. Picture 11 To be equipped with Picture 10 An...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com