Organic electroluminescent element

An electroluminescence device and a luminescence technology, which are applied in the direction of electroluminescence light sources, organic semiconductor devices, and electric solid-state devices, can solve problems such as reduced efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

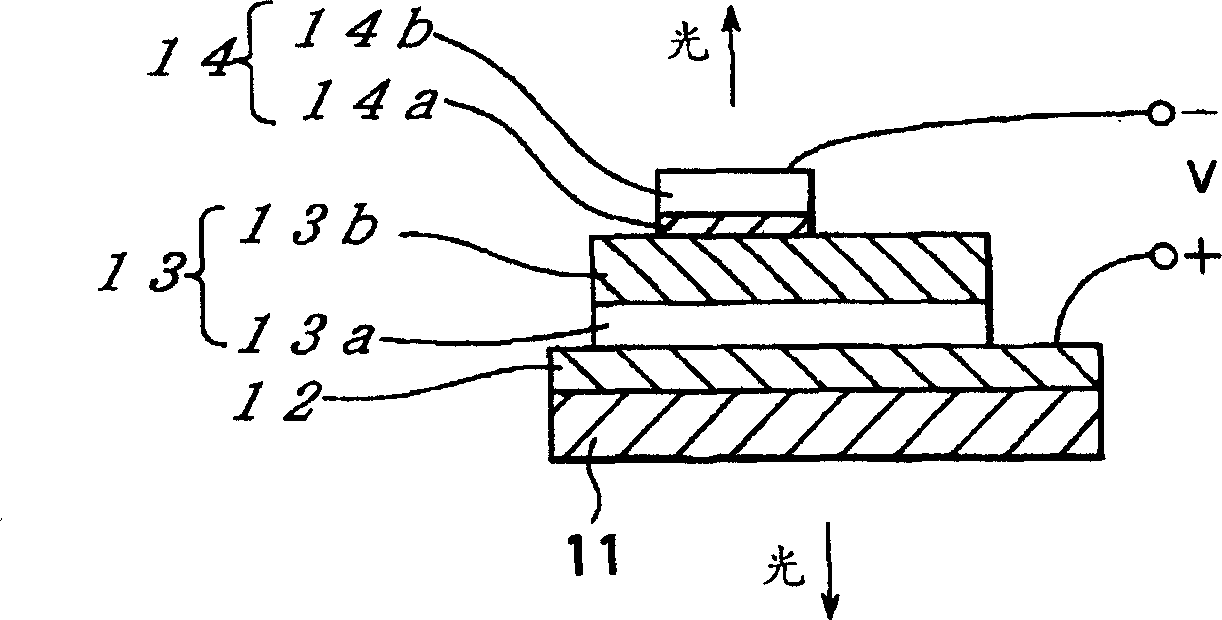

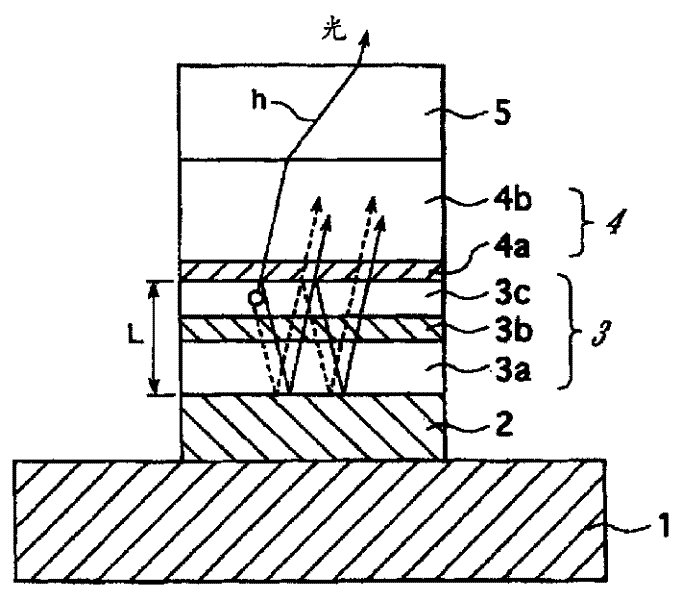

[0017] Hereinafter, an organic EL device according to the present invention will be described based on the drawings.

[0018] Now, the case where the present invention is applied to a top emission type organic EL device will be described as an example. The organic EL device described here generally has the same film configuration as the conventional case described above. That is, if figure 1 As shown, the organic EL device has a configuration in which a first electrode 2, an organic layer 3, a second electrode 4, and a passivation film 5 are sequentially stacked on a substrate 1 in this order from bottom to top.

[0019] The substrate 1 is formed of a transparent glass substrate or a semiconductor substrate.

[0020] The first electrode 2 serves as an anode that also serves as a reflective layer, and is formed of a light reflective material such as platinum (Pt), gold (Au), chrome (Cr), tungsten (W), or the like. The film thickness of the first electrode 2 is preferably set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com