Method of realizing main control plate thermal redundancy

A technology of hot backup and main control board, applied in the field of data communication, which can solve problems such as interruption of service board work, restart of service board, network single point failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

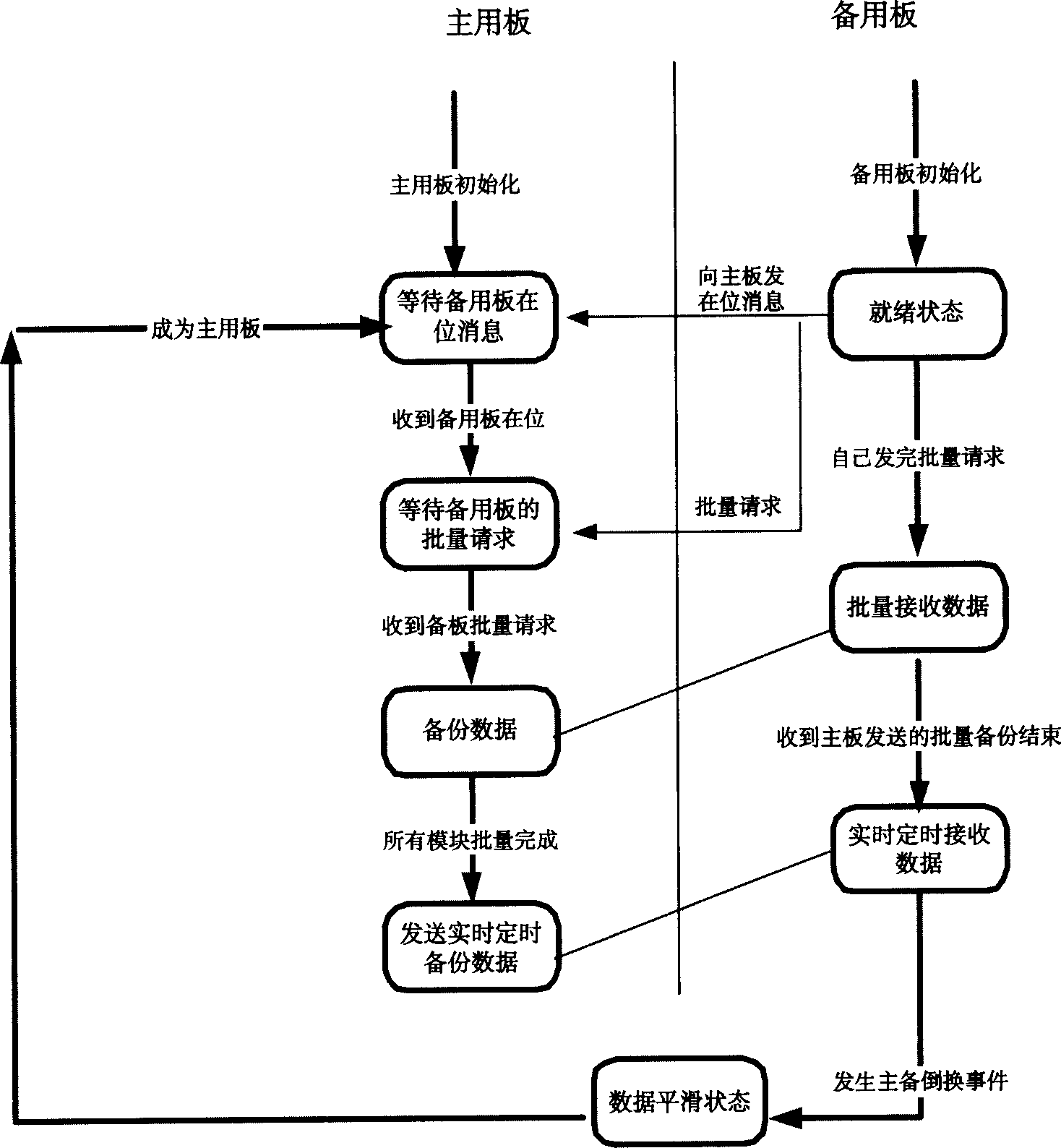

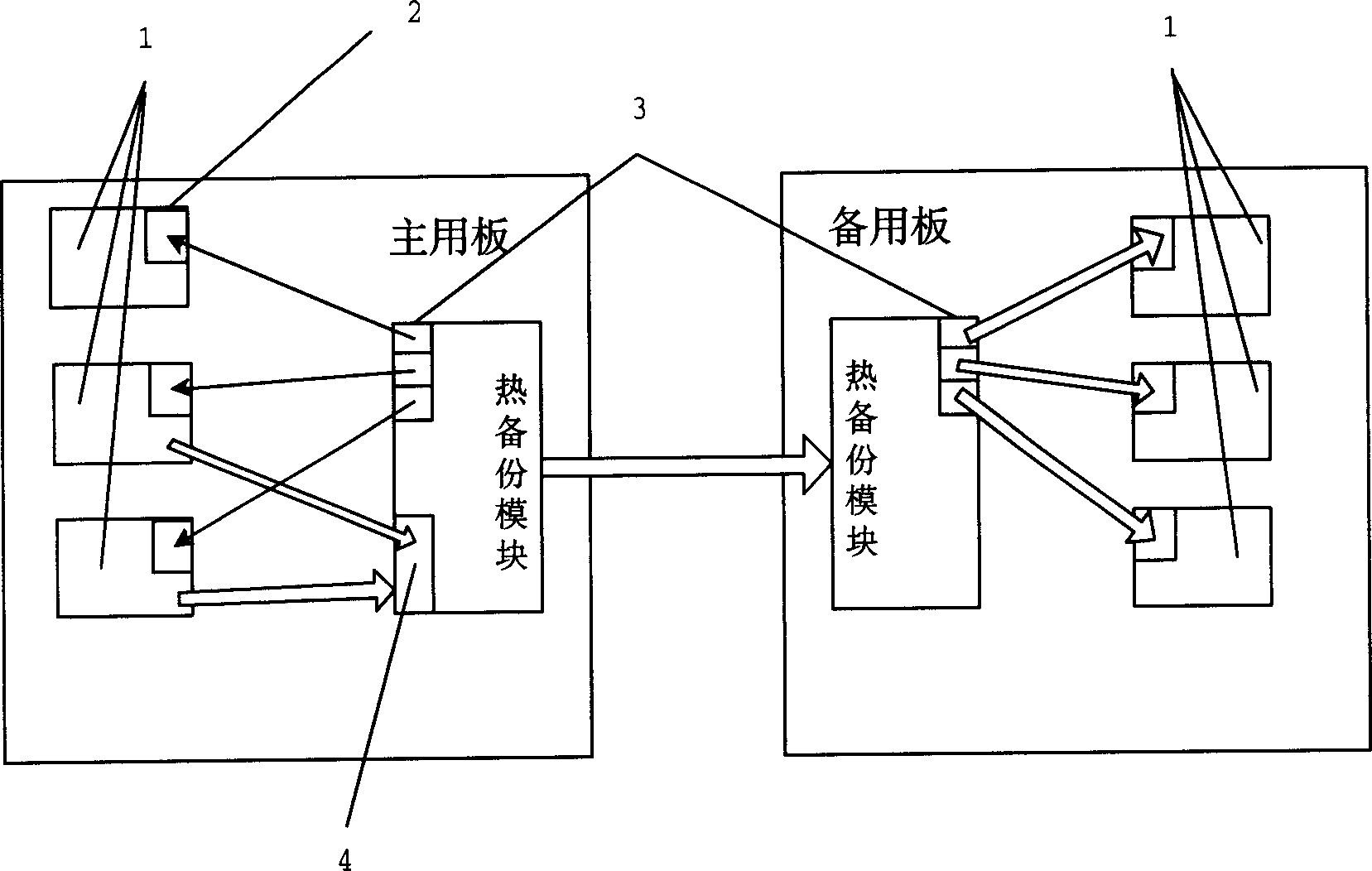

[0034] The invention is applied to distributed equipment, which is generally divided into a main control board and a service board. The main control board is used to control and manage the entire device, while the service board is responsible for forwarding data and so on. The invention designs a hot backup module to complete the backup work in a unified manner. The data module does not need to consider the backup work. It only needs to register the hot backup interface to receive the message sent by the hot backup module, pack the data, and send the data through the unified interface of the hot backup Just give the hot backup module, and the backup process is managed by the hot backup, which simplifies the design of the hot backup work of the data module.

[0035] In the method of the present invention, at first the inter-board communication modules are respectively arranged on the main control board and the service board, and the inter-board communication interface addresses...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com