Composite building board material capable of load bearing and its productioin method

A technology of building boards and composite boards, which is applied in the direction of building structures, buildings, building components, etc., to achieve the effects of fast and convenient construction, low cost and good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

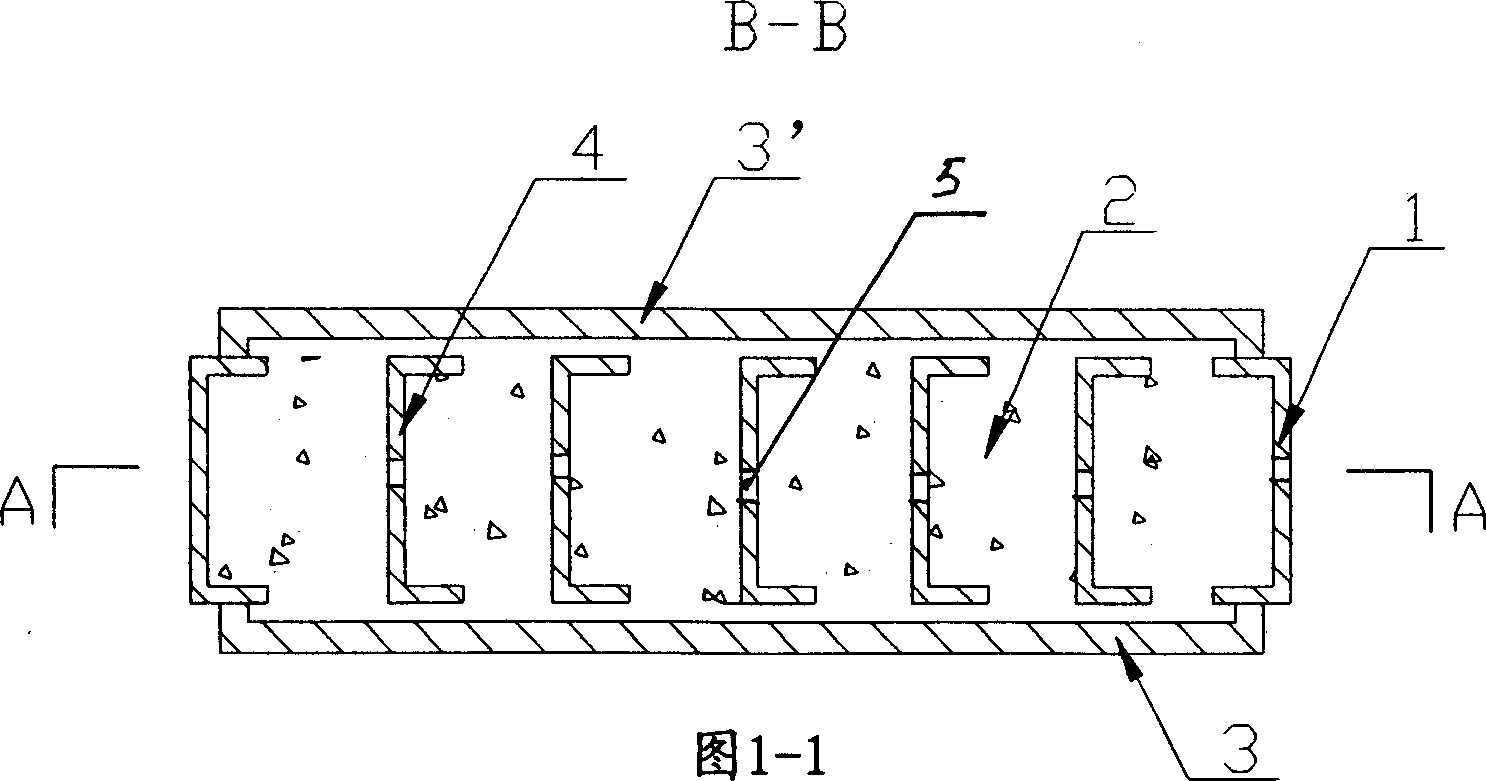

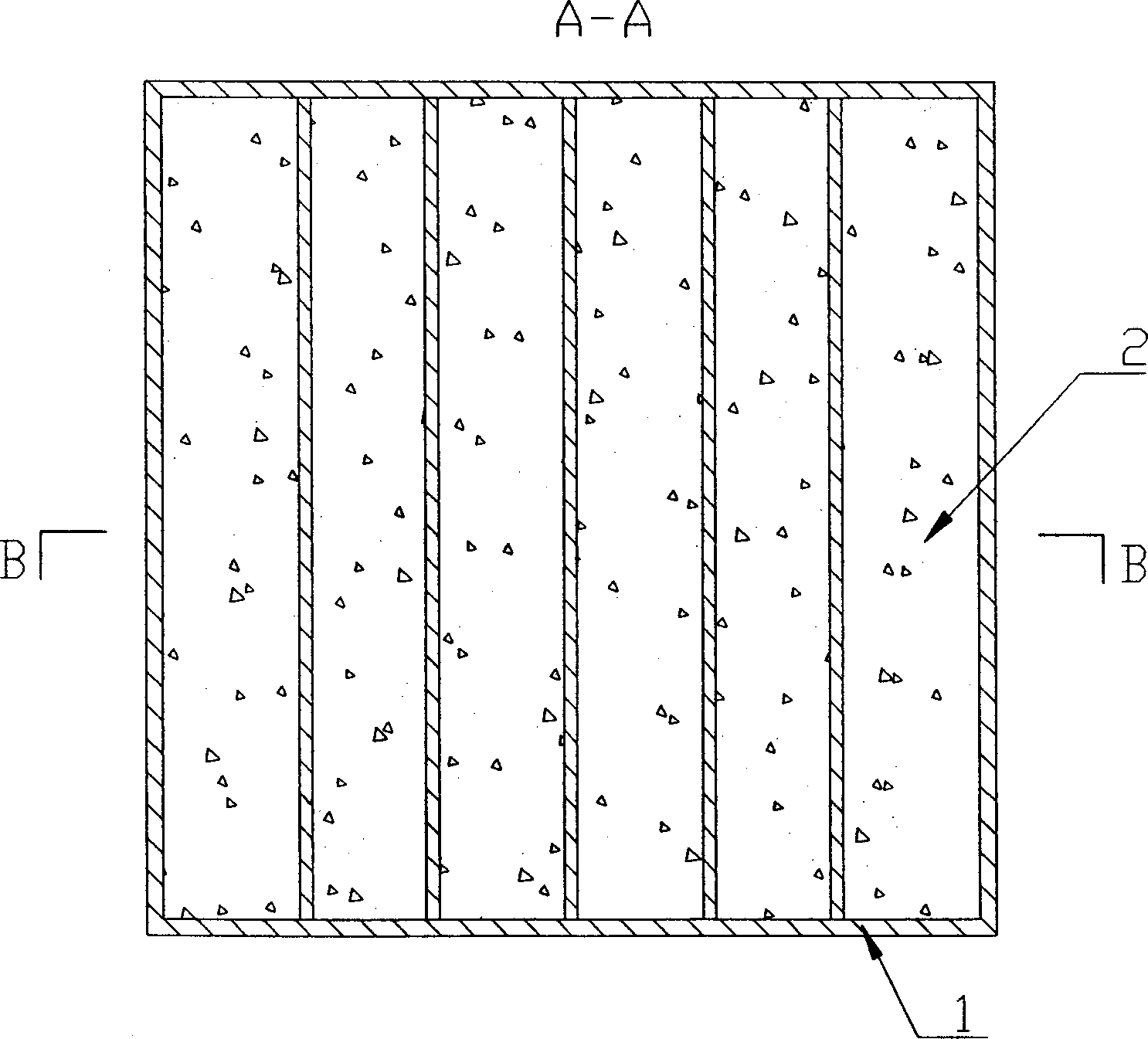

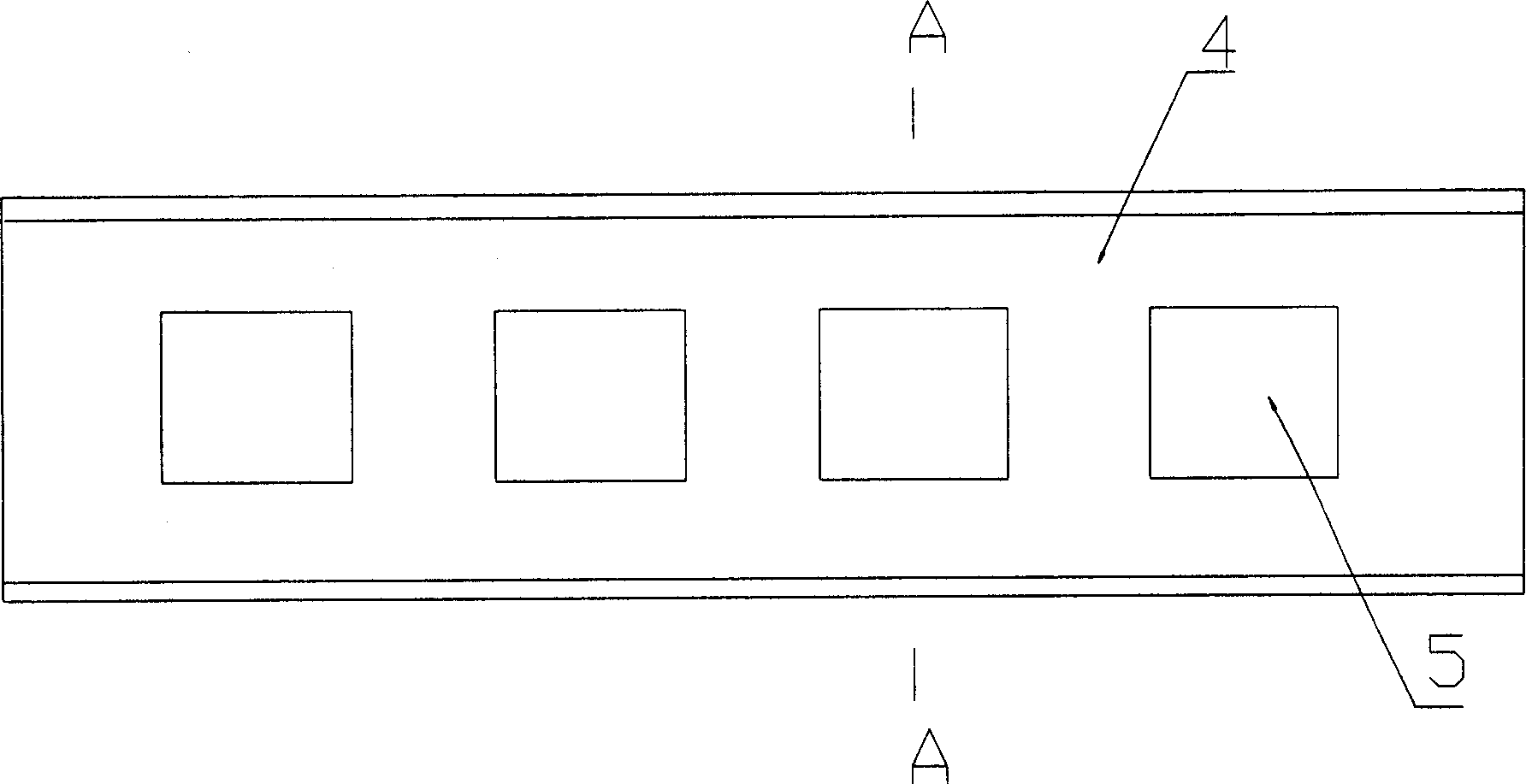

[0046] Figure 1-1~ Figure 2-2 As shown, a load-bearing foamed cement composite building board is mainly composed of an outer frame 1, a foamed cement layer 2 and a surface layer 3, 3', and is characterized in that: in the outer frame 1, one-way (or multi-directional) to set several load-bearing channel steels 4; and on the channel steels 4 are provided with several holes 5 through which foamed cement can penetrate; and the outer frame 1 is filled with foamed cement fillers to form foamed Cement layer 2; on both surfaces of the foamed cement layer 2, a surface layer 3 reinforced by anti-cracking material is arranged.

[0047] The manufacturing method of the present invention comprises:

[0048] 1. First, place the steel structure formed by the outer frame 1 and several load-bearing channel steels 4 with holes 5 in one direction on the formwork;

[0049] 2. After stirring the cement slurry evenly according to a certain proportion, a certain amount of cement slurry can be pour...

Embodiment 2

[0057] As shown in Figure 1-1, Figure 1-2 ,Figure 3-1, Figure 3-2 As shown, a load-bearing foamed cement composite building board is mainly composed of an outer frame 1, a foamed cement layer 2 and a surface layer 3. It is characterized in that: one-way (or multi-directional) in the outer frame 1 A plurality of load-bearing steel truss composite structures 7 composed of angle steel 44 and Z-shaped steel bars 6 are set; and the outer frame 1 is filled with foamed cement filler to form a foamed cement layer 2; Both surfaces of the foamed cement layer 2 are provided with surface layers 3 reinforced by crack-resistant materials.

[0058] The manufacturing method of the present invention comprises:

[0059] 1. First, place the outer frame 1 and several load-bearing steel truss composite structures 7 composed of angle steel and Z-shaped steel bars welded in one direction on the production template;

[0060] 2. After stirring the cement slurry evenly according to a certain propor...

Embodiment 3

[0070] As shown in Figure 1-1, Figure 1-2 ,Pic 4-1, Figure 4-2 As shown, a load-bearing foamed cement composite building board is mainly composed of an outer frame 1, a foamed cement layer 2 and a surface layer 3. It is characterized in that: one-way (or multi-directional) in the outer frame 1 Set up several load-bearing steel truss composite structures 9 composed of C-shaped steel 8 and Z-shaped steel bars 6 on both sides welded; and fill the outer frame 1 with foamed cement filler to form the foamed cement layer 2; On the two surfaces of the foamed cement layer 2, a surface layer 3 reinforced by anti-cracking material is arranged.

[0071] Its manufacturing method can be selected from Embodiment 1 or Embodiment 2, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com