Gas subfebrile temperature in pression shaping method

A technology of micro-hot embossing and molding method, which is applied to other household appliances, optical components, household appliances, etc., can solve the problems of coral reefs, poor thickness uniformity, warping, etc., and achieves cost reduction, simplified manufacturing process, and excellent dimensional accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

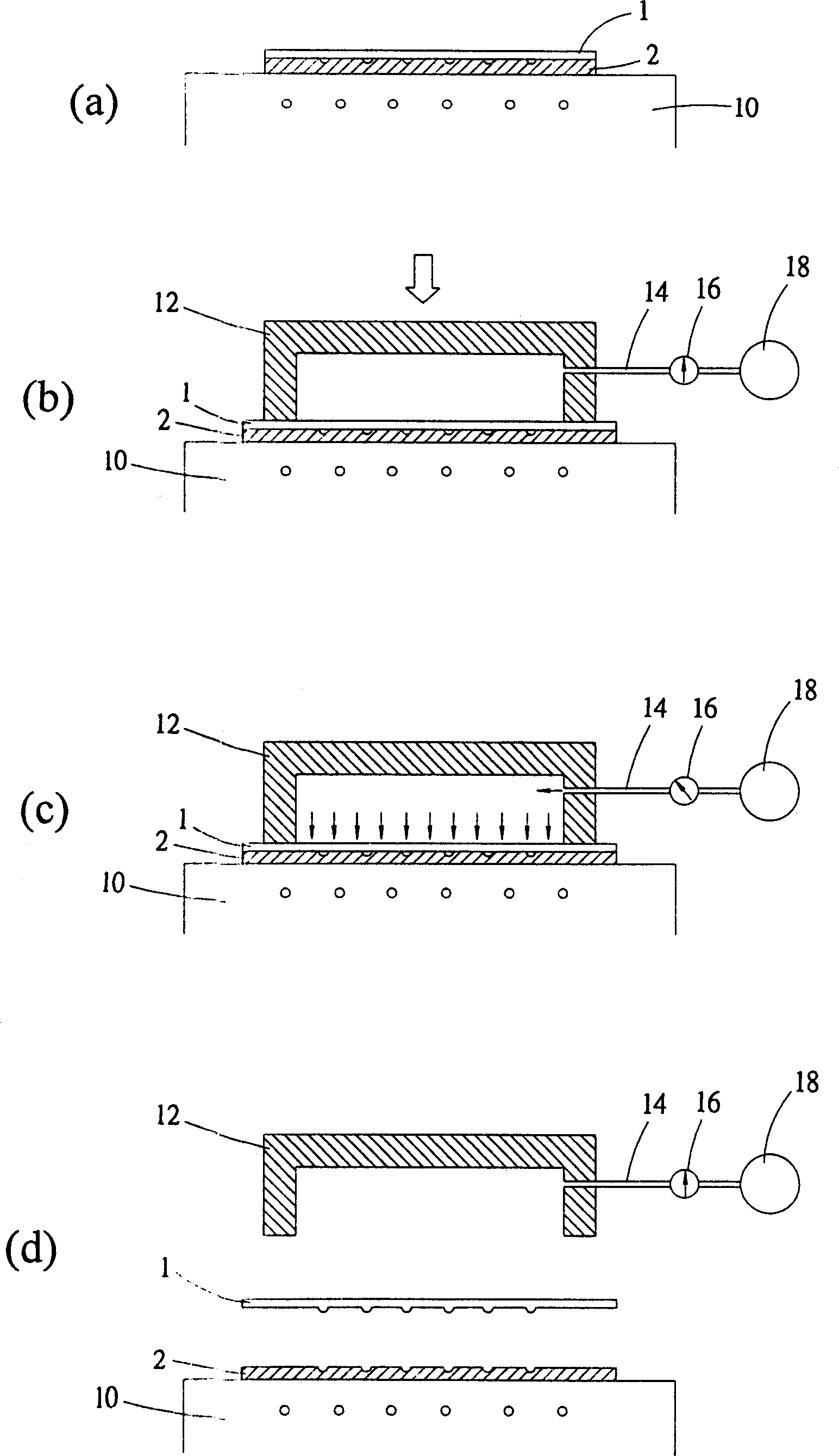

[0029] figure 1 (a) to 1(d) show the first embodiment of the gas microthermal imprint molding method according to the present invention. Such as figure 1 As shown in (a), the plastic film material (PC film) 1 as the mark to be imprinted is laid flat on the mold 2 with a predetermined microstructure in advance, and the side of the mold 2 with the microstructure and the mark to be imprinted To contact. The plastic / mold stacking combination formed in this way is set on the heating and cooling plate 10 as a workbench, and the heating and cooling plate can be used to heat and cool the plastic.

[0030] Then as figure 1 As shown in (b), a closed cavity 12 is covered on this plastic / mold stack combination, and the plastic / mold stack forms a closed space, and the closed cavity is connected to a hydraulic or crank (not shown in the figure) for rapid The airtight cavity is opened and closed. The sealed chamber is connected to a high-pressure gas compressor 18 and a pressure control valv...

Embodiment 2

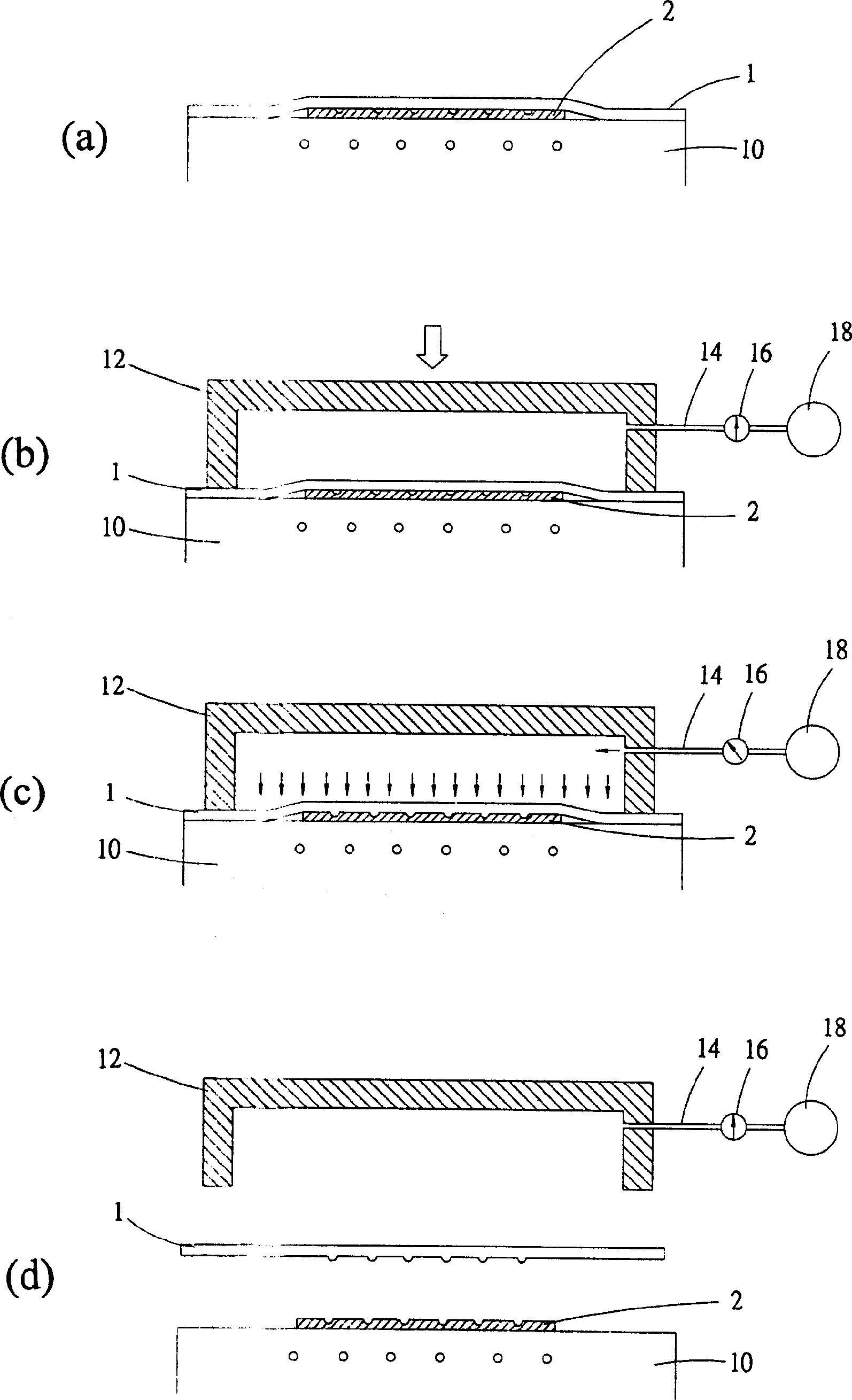

[0034] figure 2 (a) to 2(d) show the second embodiment of the gas micro hot stamping molding method according to the present invention, except that the hot stamping mold 2 used is a brittle material (such as a silicon wafer master mold, a glass master mold) And the sealed cavity 12 is to press the plastic film 1 as the mark to be imprinted to completely cover the mold 2 and the remaining part is not directly pressed on the mold 2. The other operation methods and conditions are the same as in the first embodiment.

Embodiment 3

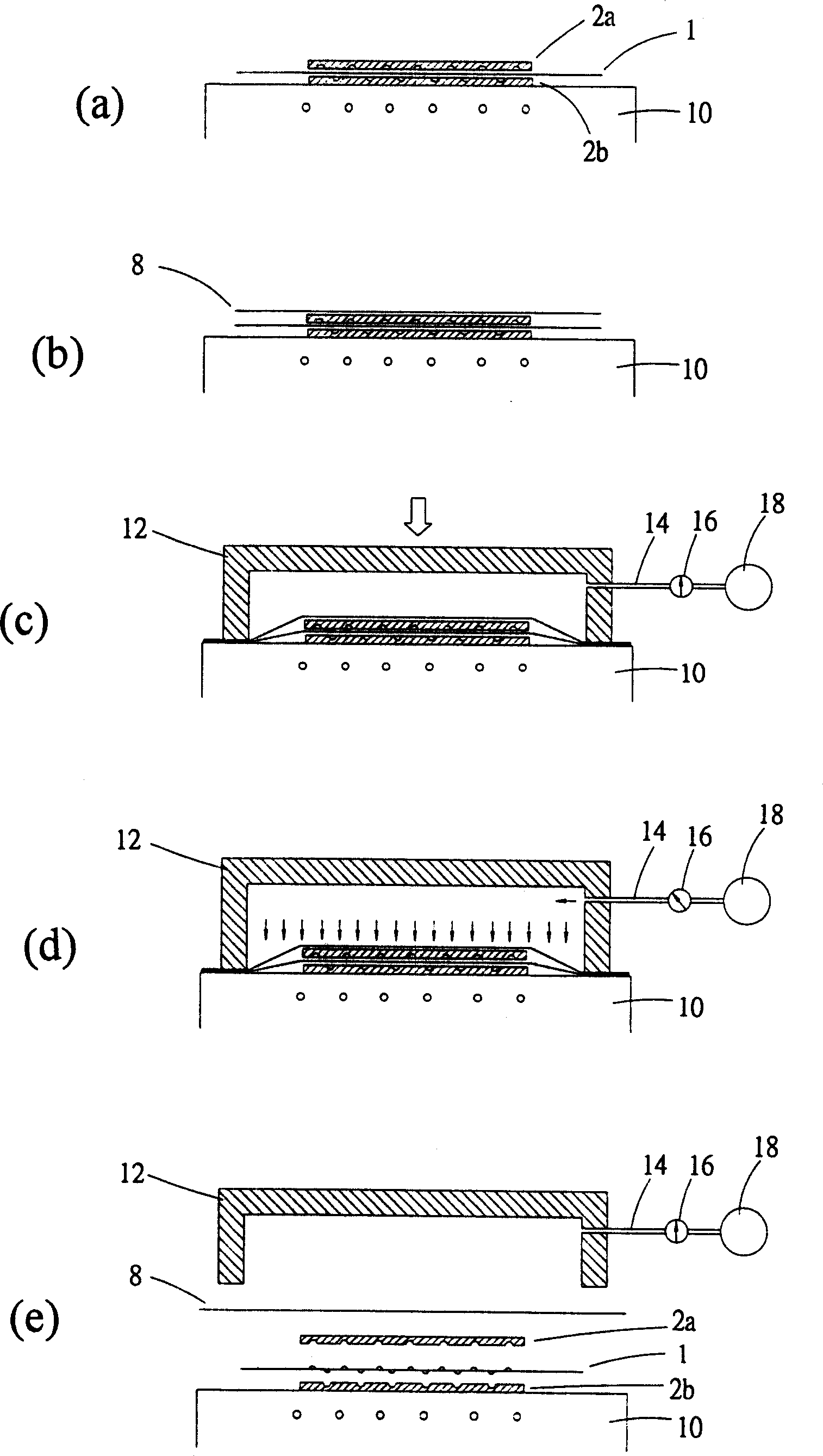

[0036] image 3 (a) to 3(e) show a third embodiment according to the present invention for molding a dual-surface microstructure element. Such as image 3 As shown in (a), the molding plastic film material (such as PC film) 1 as the mark to be imprinted is sandwiched between the upper and lower molds 2a and 2b to make it an upper mold / plastic film / lower mold Sandwich stacking combination. The upper mold and the lower mold respectively have microstructures formed on the upper mold. When forming a sandwich stack, the surfaces of the upper mold and the lower mold with the microstructures are opposed to each other, and the plastic film 1 is sandwiched between them. The sandwich stack combination of the upper mold / plastic film / lower mold is placed on a heating and cooling plate 10 as a workbench, and the heating and cooling plate 10 can be used to heat and cool the plastic.

[0037] Next, as shown in Figure (3b), a piece of sealing film 8 is laid flat on the sandwich stack combination...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com