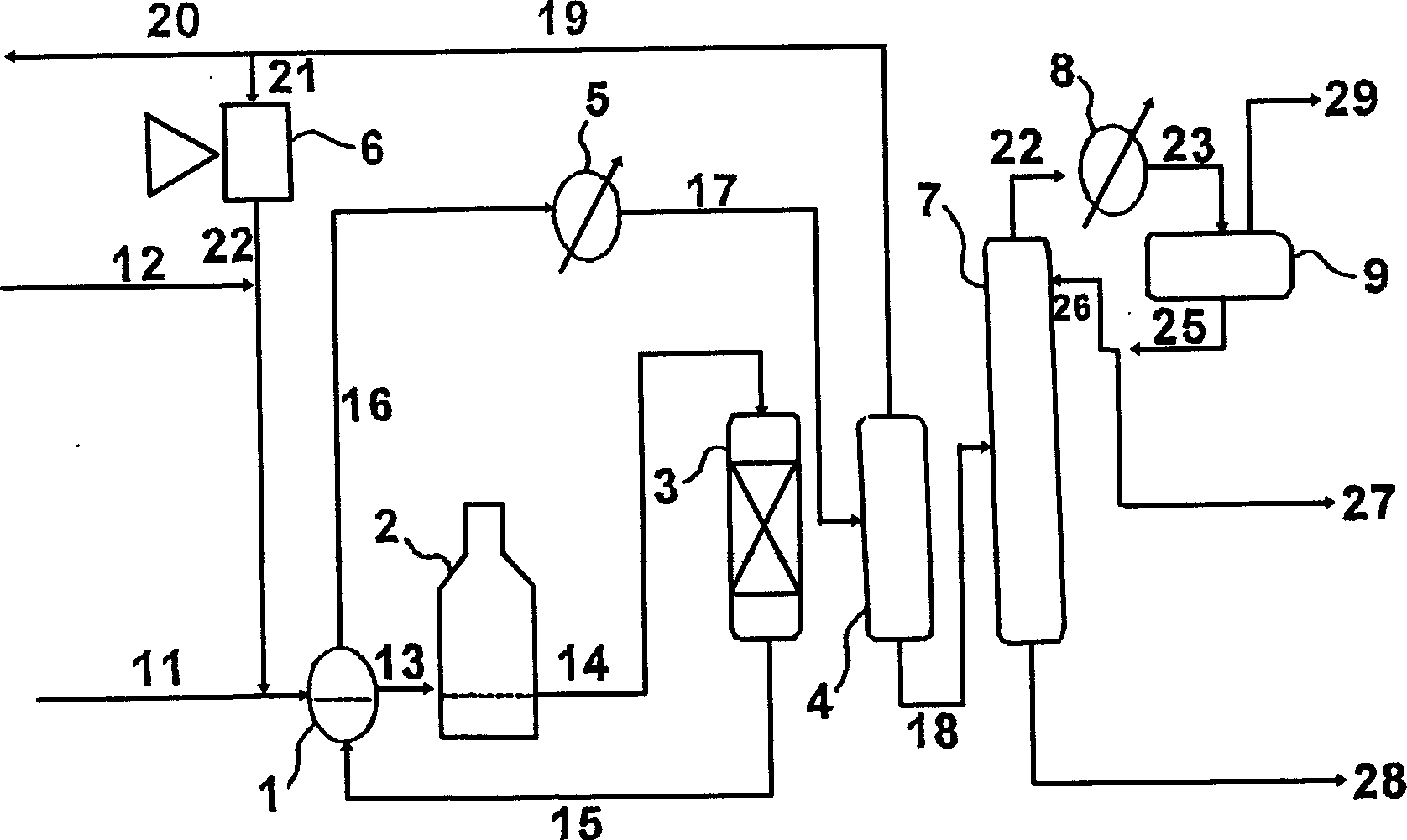

Process for producing aromatic hydrocarbon compounds and liquefied petroleum gas from hydrocarbon feedstock

A technology for aromatic hydrocarbon compounds and liquefied petroleum gas, applied in the field of producing aromatic hydrocarbon compounds and liquefied petroleum gas from hydrocarbon raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Mordenite having a silica / alumina molar ratio of 20 was mixed with γ-alumina as an inorganic binder, and then shaped into a mixed carrier having a mordenite content of 75% by weight. In step, add H to it 2 PtCl 6 aqueous solution and SnCl 2 of aqueous solution. At this time, 0.05 parts by weight of platinum and 0.5 parts by weight of tin were added to the mixed carrier based on 100 parts by weight of the mixed carrier composed of mordenite and the binder. After being formed into a diameter of 1.5 mm and a length of 10 mm, it was dried at 200° C. for 12 hours, and then calcined at 500° C. for 4 hours to obtain a catalyst.

[0049] By using the catalyst prepared above, a reaction test was carried out, the conditions and results of which are listed in Table 1 below.

Embodiment 2

[0051] A ZSM-5 type zeolite having a silica / alumina molar ratio of 30 was mixed with γ-alumina as an inorganic binder, and then formed into a mixed carrier having a ZSM-5 type zeolite content of 75% by weight. In step, add H to it 2 PtCl 6 aqueous solution and SnCl 2 of aqueous solution. At this time, 0.05 parts by weight of platinum and 0.5 parts by weight of tin were added to the mixed carrier based on 100 parts by weight of the mixed carrier composed of the ZSM-5 type zeolite and the binder. After being formed into a diameter of 1.5 mm and a length of 10 mm, it was dried at 200° C. for 12 hours, and then calcined at 500° C. for 4 hours to obtain a catalyst.

[0052] By using the catalyst prepared above, a reaction test was carried out, the conditions and results of which are listed in Table 1 below.

Embodiment 3

[0054] A ZSM-5 type zeolite having a silica / alumina molar ratio of 30 was mixed with γ-alumina as an inorganic binder, and then formed into a mixed carrier having a ZSM-5 type zeolite content of 75% by weight. In step, add H to it 2 PtCl 6 aqueous solution and Pb(NO 3 ) 2 of aqueous solution. At this time, 0.05 parts by weight of platinum and 0.15 parts by weight of lead were added to the mixed carrier based on 100 parts by weight of the mixed carrier composed of the ZSM-5 type zeolite and the binder. After being formed into a diameter of 1.5 mm and a length of 10 mm, it was dried at 200° C. for 12 hours, and then calcined at 500° C. for 4 hours to obtain a catalyst.

[0055] By using the catalyst prepared above, a reaction test was carried out, the conditions and results of which are listed in Table 1 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com