Lighting device for high-pressure discharge lamp

A technology for high-pressure discharge lamps and discharge lamps, which is applied to discharge lamps, lighting devices, circuits, etc., and can solve problems such as reduction of light beams and blackening of discharge containers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Hereinafter, the present invention will be described using examples.

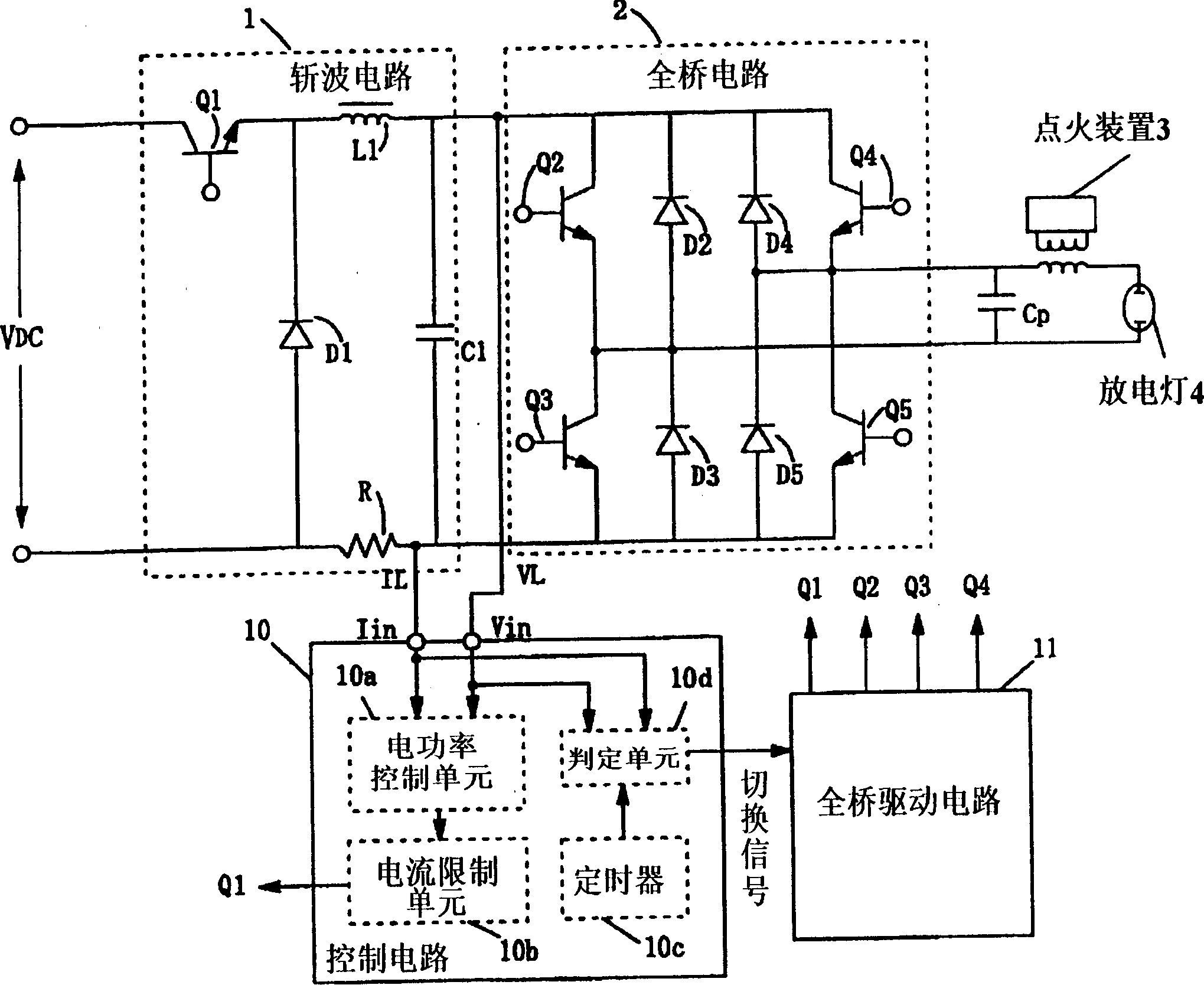

[0033] figure 1 It is a configuration diagram showing a high-pressure discharge lamp lighting device according to an embodiment of the present invention. This figure shows the configuration of a lighting circuit using a full-bridge circuit, but a half-bridge circuit or a push-pull circuit can also be used.

[0034] As shown in this figure, the circuit of the present embodiment consists of a step-down chopper circuit 1 supplying DC voltage; a full bridge circuit 2 that connects the output terminal of the step-down chopper circuit 1 to convert the DC voltage into a rectangular wave voltage; and The ignition device 3 that generates high-voltage pulses when the lamp is started is constituted, and the AC rectangular wave voltage or DC voltage output by the full bridge circuit 2 is applied to the discharge lamp 4 . A bypass capacitor Cp is connected in parallel to the output end of the full bridge circui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com