Continuous mining method of stepped sectional extruding and ore caving followed by filling

A step-by-step, mining-method technology, applied in surface mining, underground mining, special mining, etc., can solve the problems of high operating costs, poor safety conditions, and low working face labor productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further elaborated below in conjunction with accompanying drawing:

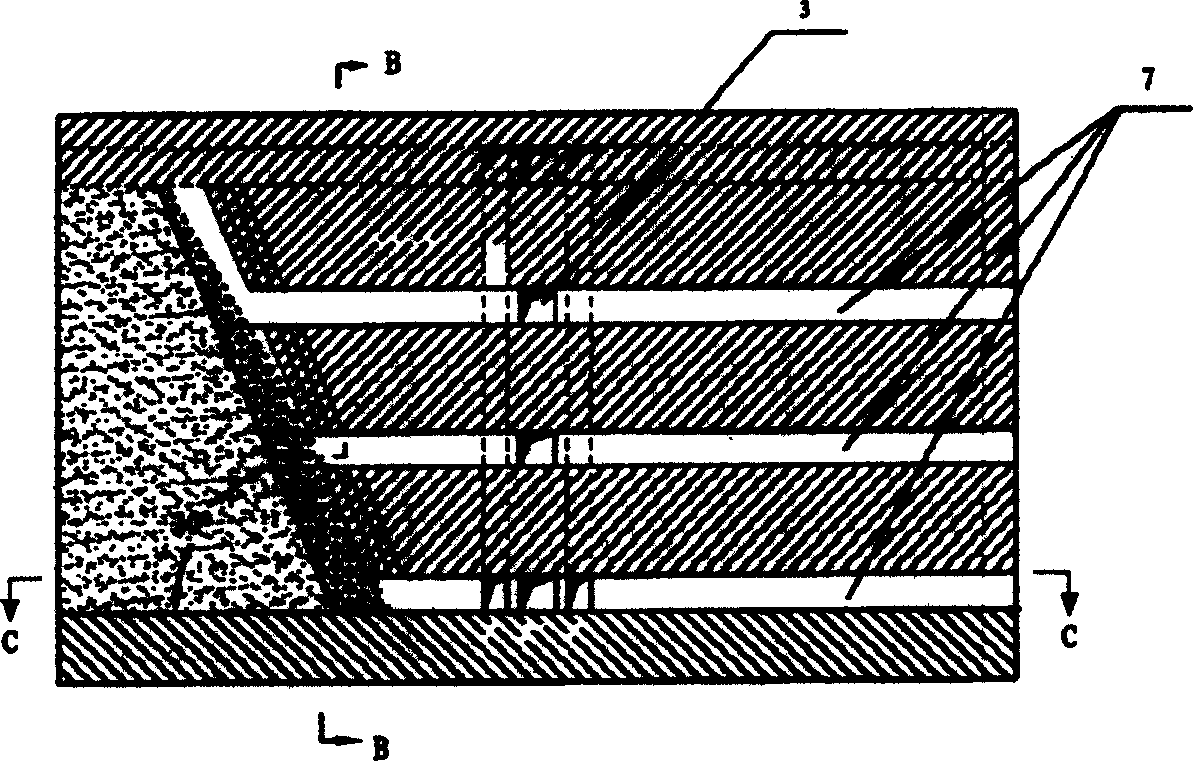

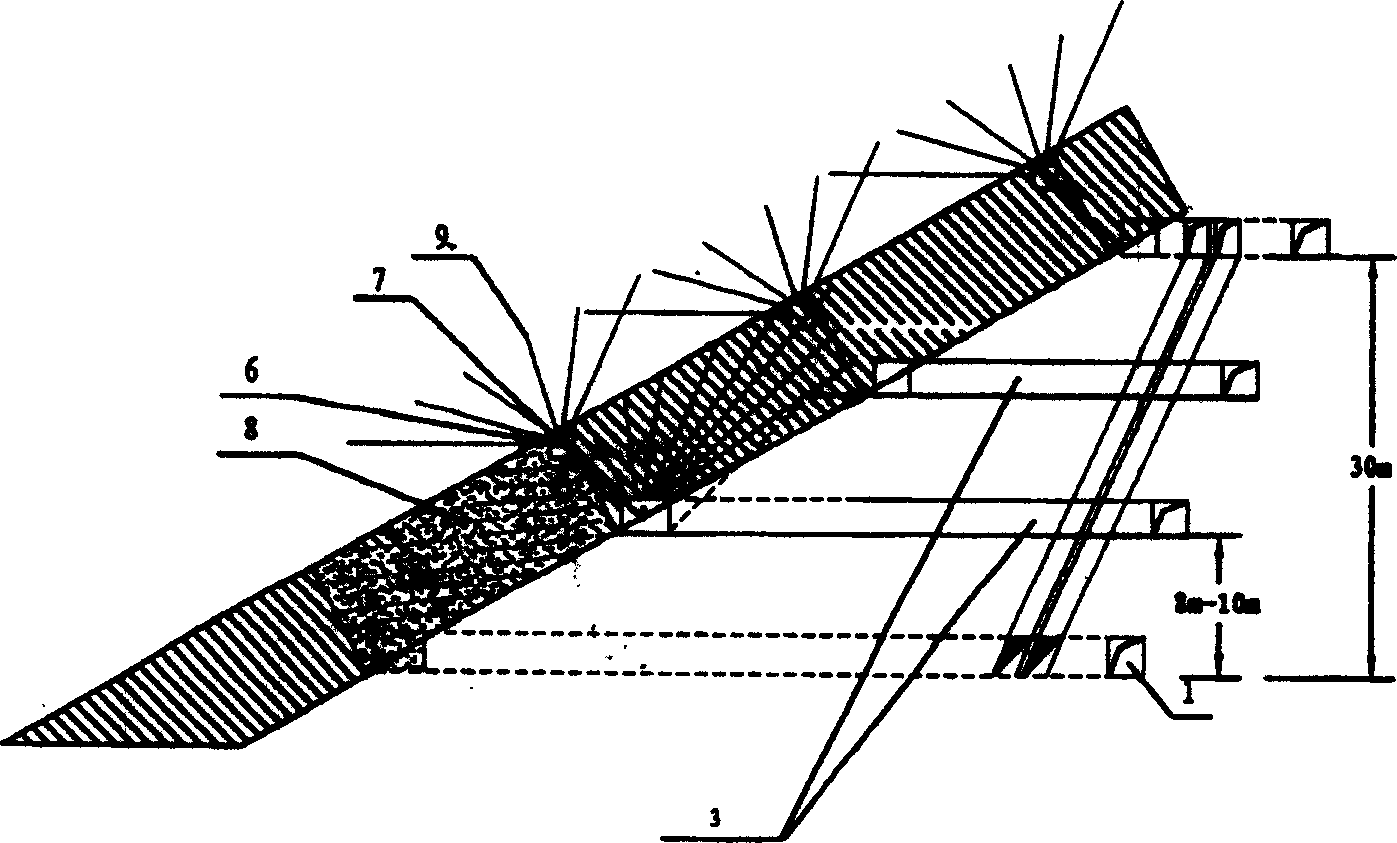

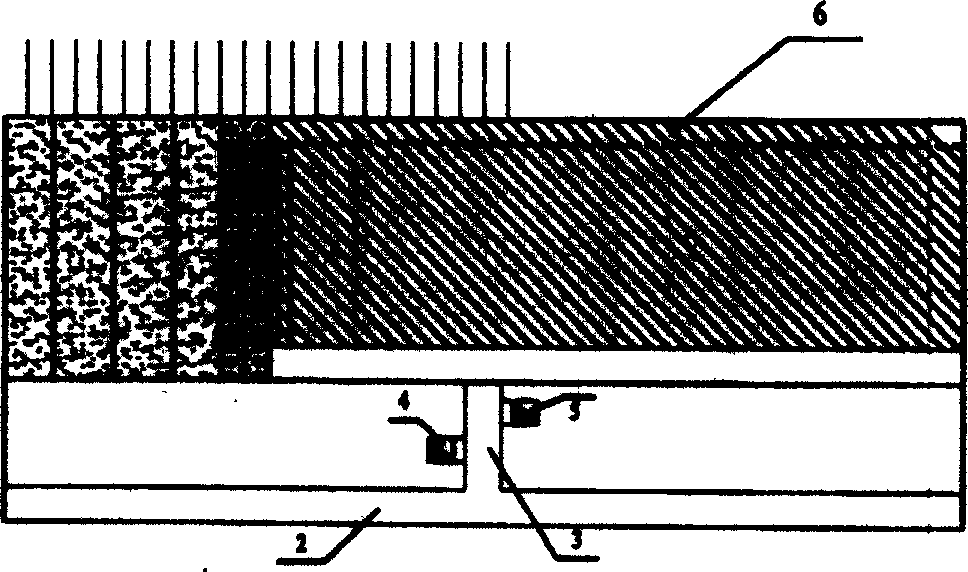

[0021] ① Divide the ore body into a middle section with a height of 80-90m. The middle section is divided into three small middle sections with a height of 30m. Each small middle section is divided into three sections along the strike with a section height of 10m.

[0022] ② Divide the ore section along the strike. The length of the ore section can be 120m. Each section is arranged at the boundary of the footwall of the orebody along the veins to drill out the ore roadway, and its cross-sectional size can be 4m×3m; Ventilation, filling and roof protection roadways are arranged at the position of the wall, and the roadway can also play a role in exploring the boundary line of the hanging wall of the ore body.

[0023] ③ Use the forward-inclined fan-shaped medium-deep hole for ore falling, use the non-electric conduction detonation millisecond detonator in the same row and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com