Medical refuse pyrolytic-gasification incineration apparatus

A technology for pyrolysis and gasification, medical waste, applied in incinerators, combustion methods, combustion types, etc., can solve the problem of high operating costs, difficult to remove dioxins, and the emission of dioxin-like highly toxic substances cannot be fundamentally solved. to solve problems such as saving fuel costs, reducing production conditions and reducing sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

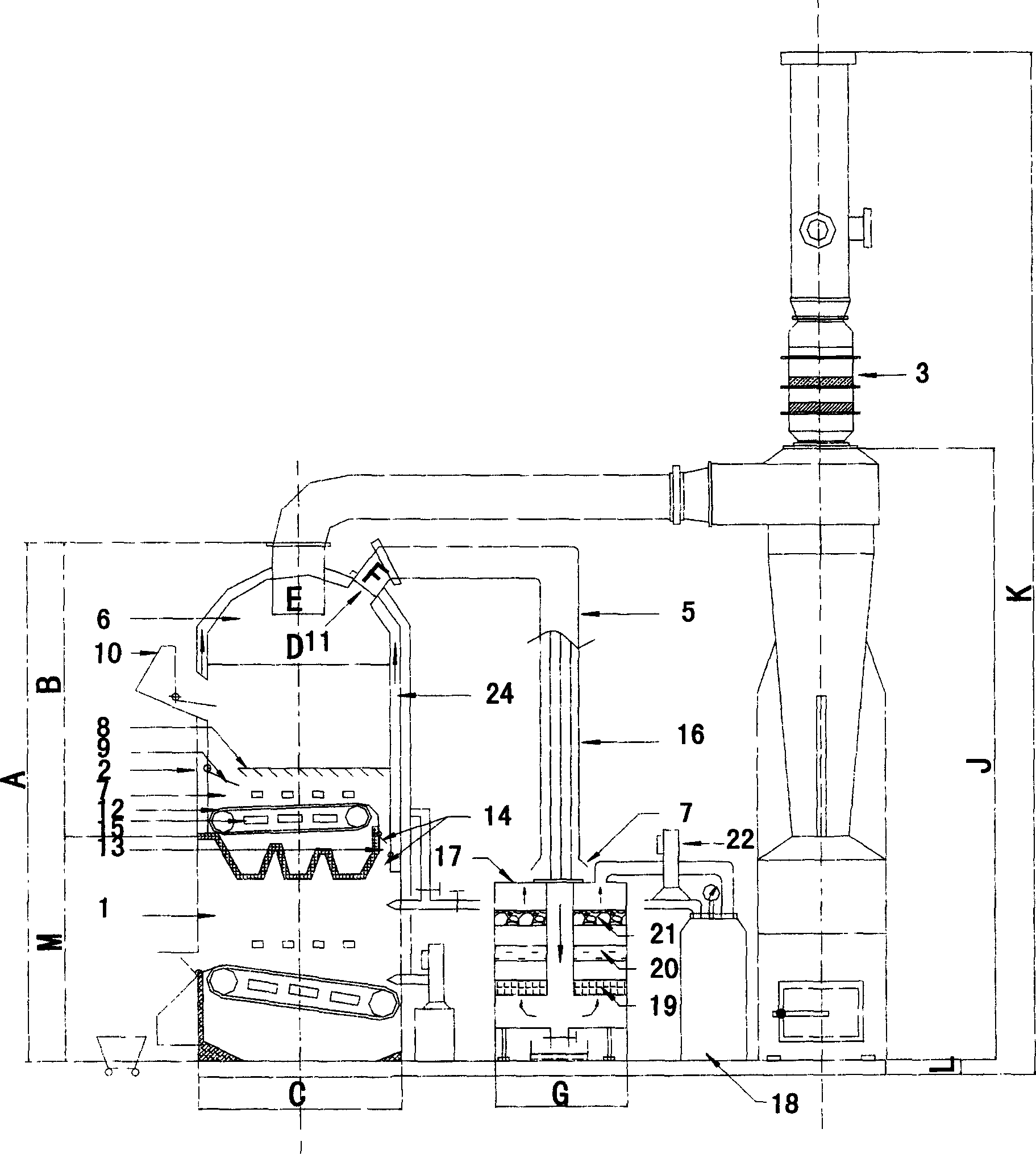

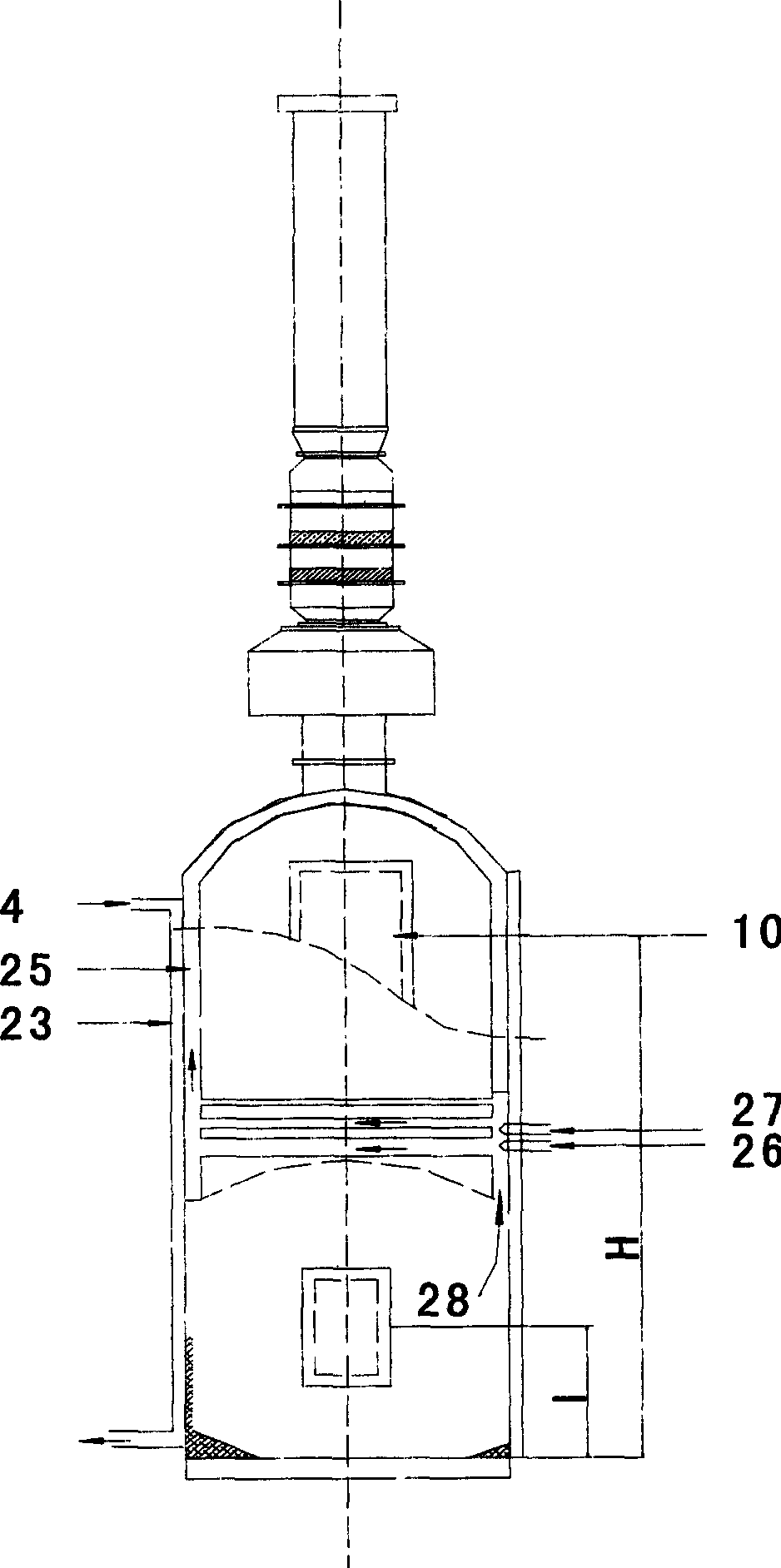

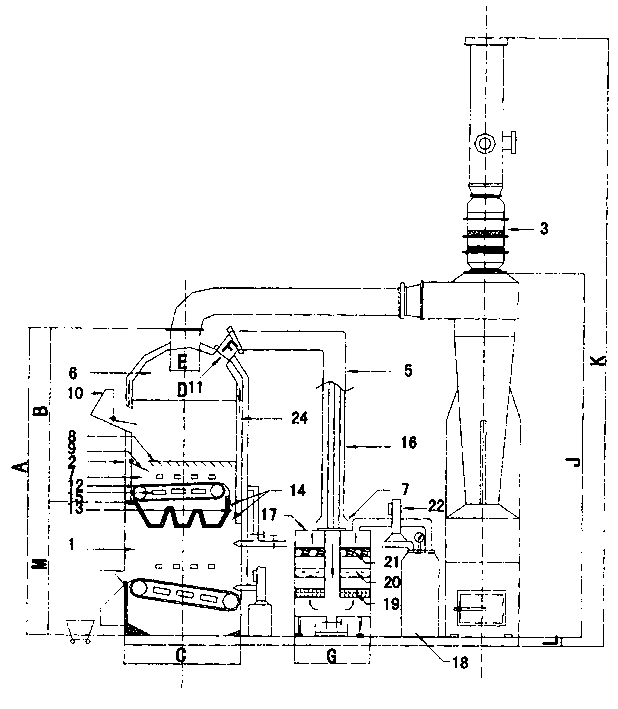

[0009] The overall height of the designed medical waste pyrolysis gasification incinerator body is A (3100mm), and the outer diameter is C (1200mm). It is divided into upper and lower two-layer structure, the lower layer is the incinerator (1) with a height of M (1300mm), the upper layer is the pyrolysis gasifier (2) with a height of B (1800mm), and the outer diameter is D (1000mm). There are water walls. The base height is L (150mm), and the total floor area is 3750×2100m 2 . According to the pyrolysis gasification furnace (2) top 0.5m side is provided with a cracked gas outlet with an opening diameter of F (200mm), the cracked gas outlet is directly connected with the cracked gas-air heat exchanger by the flange, and the cracked gas -The other end of the air heat exchanger is connected to the filter tank (17) whose outer diameter is G (600mm) by a flange. The bottom of the filter tank (17) is provided with a decontamination valve, and the filter tank (17) is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com