Flow control of extruder

A technology of compressors and expanders, which is applied to compressors using turbines, irreversible cycle compressors, refrigerators, etc., and can solve problems such as waste of power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

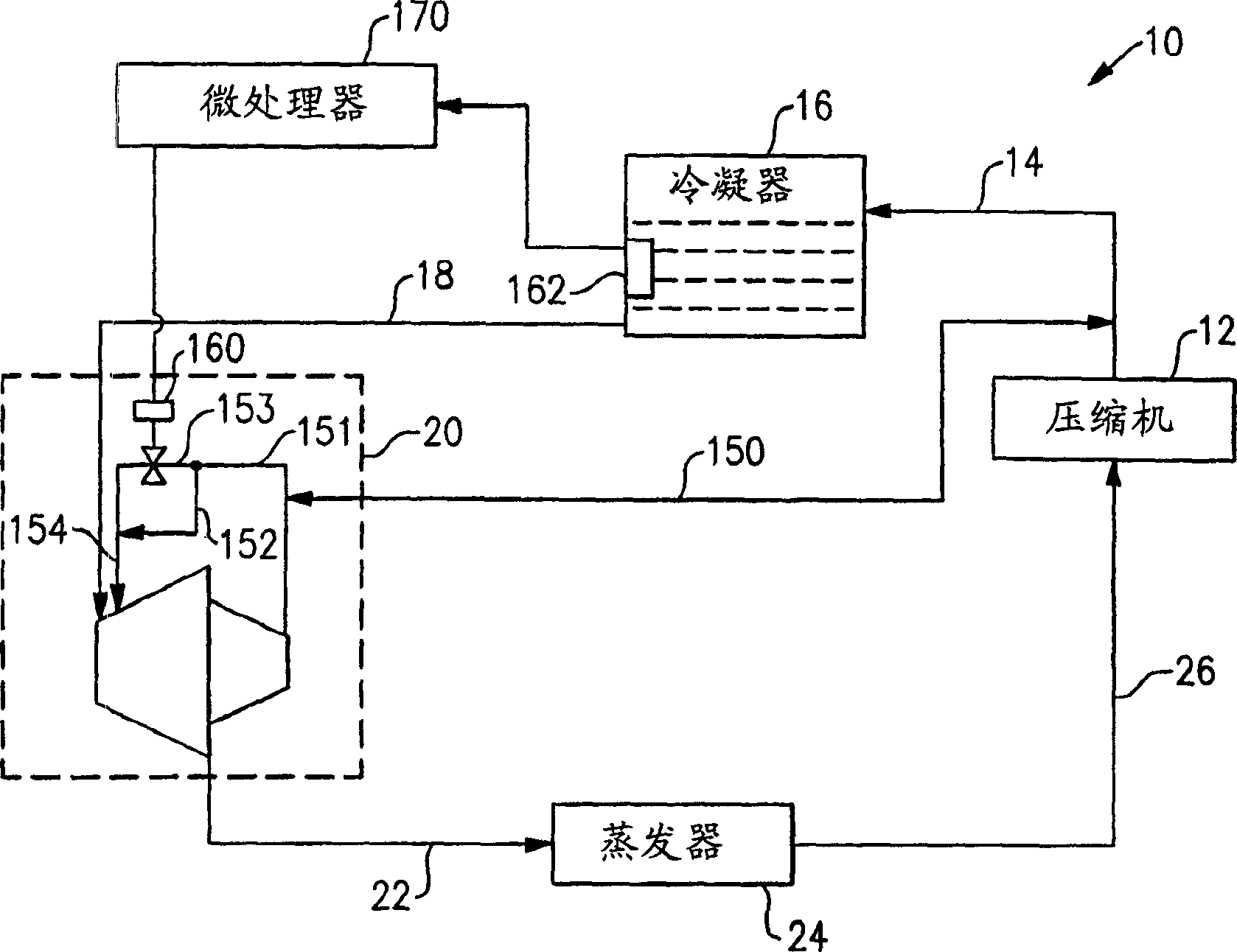

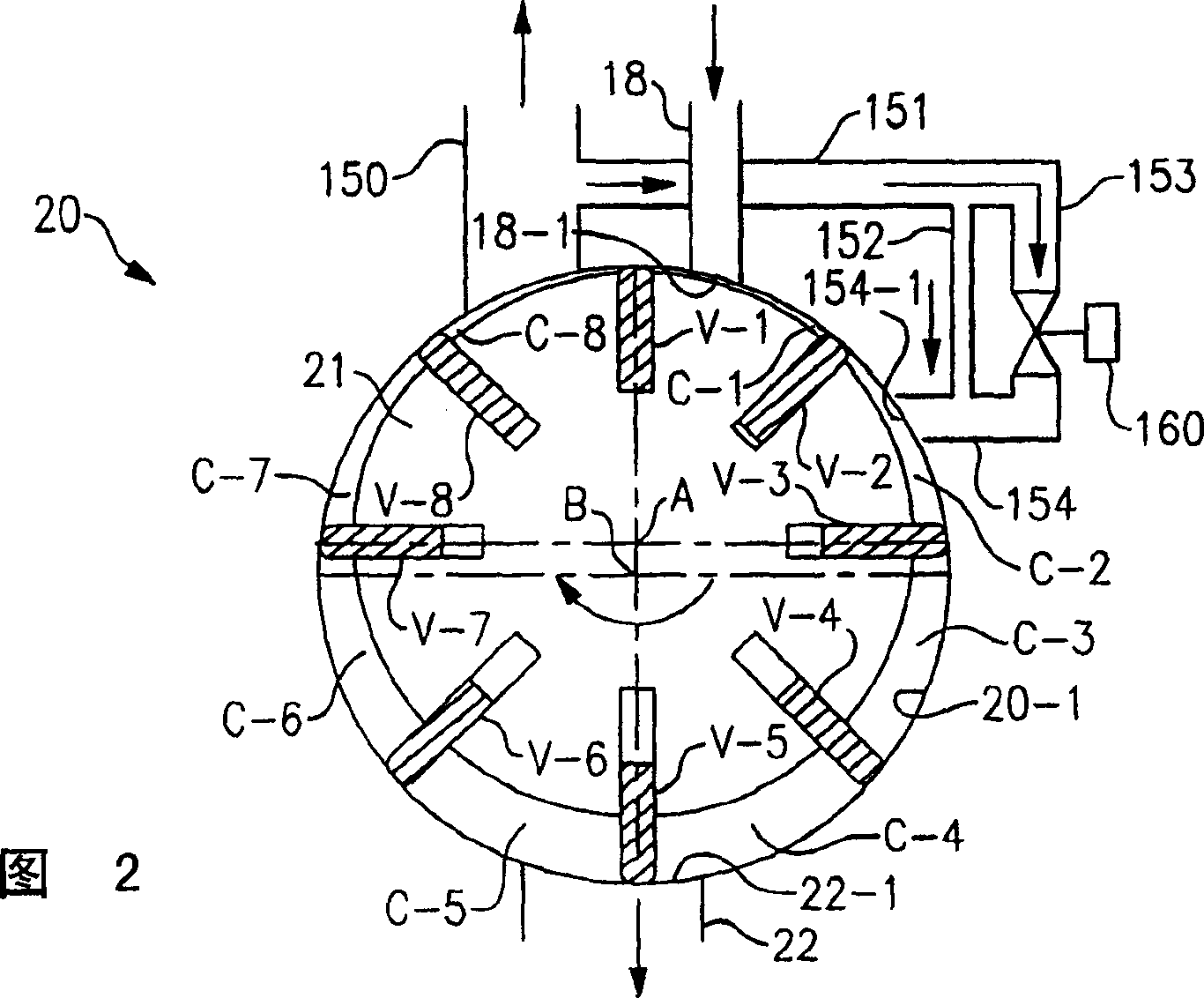

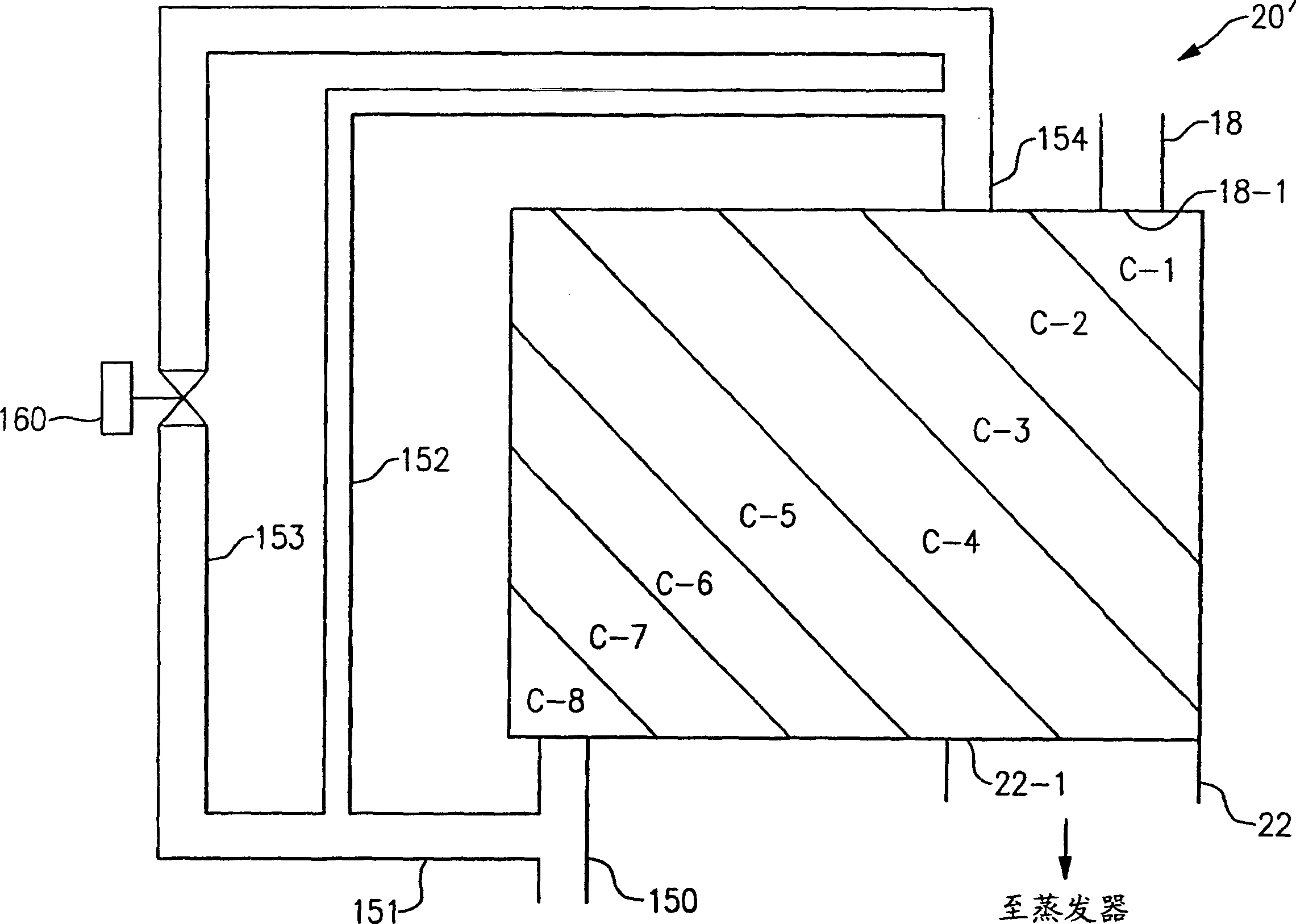

[0015] exist figure 1 , reference numeral 10 generally denotes a refrigeration system or an air conditioning system. The system 10 comprises in sequence, starting from the compressor 12, a discharge line 14, a condenser 16, a line 18, an expansion device in the form of an extractor 20, a line 22, an evaporator 24 and a suction line 26, so that the complete the loop. Referring to Figure 2, the extruder 20 shown is a rotating vane device that nominally uses half of each revolution as an expander and half of each revolution as a compressor, so the extruder 20 is a two-stage device that is effectively balanced in terms of loads and the like. As shown, the extruder 20 has a rotor 21 about an axis of rotation A and eight symmetrically circumferentially spaced vanes, designated V-1 to V-8, respectively. Vanes V-1 to V-8 seal against the cylinder wall defined by cylinder 20-1 due to centrifugal force, or are spring biased into contact with the cylinder wall if necessary or desired....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com