Environment-protecting prefabricated roof for replacing wooden one

A technology of prefabricated parts and wood products, applied in the field of prefabricated parts of building roofs, can solve problems such as easy to cause fire, non-compliance with environmental protection requirements, and need for maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

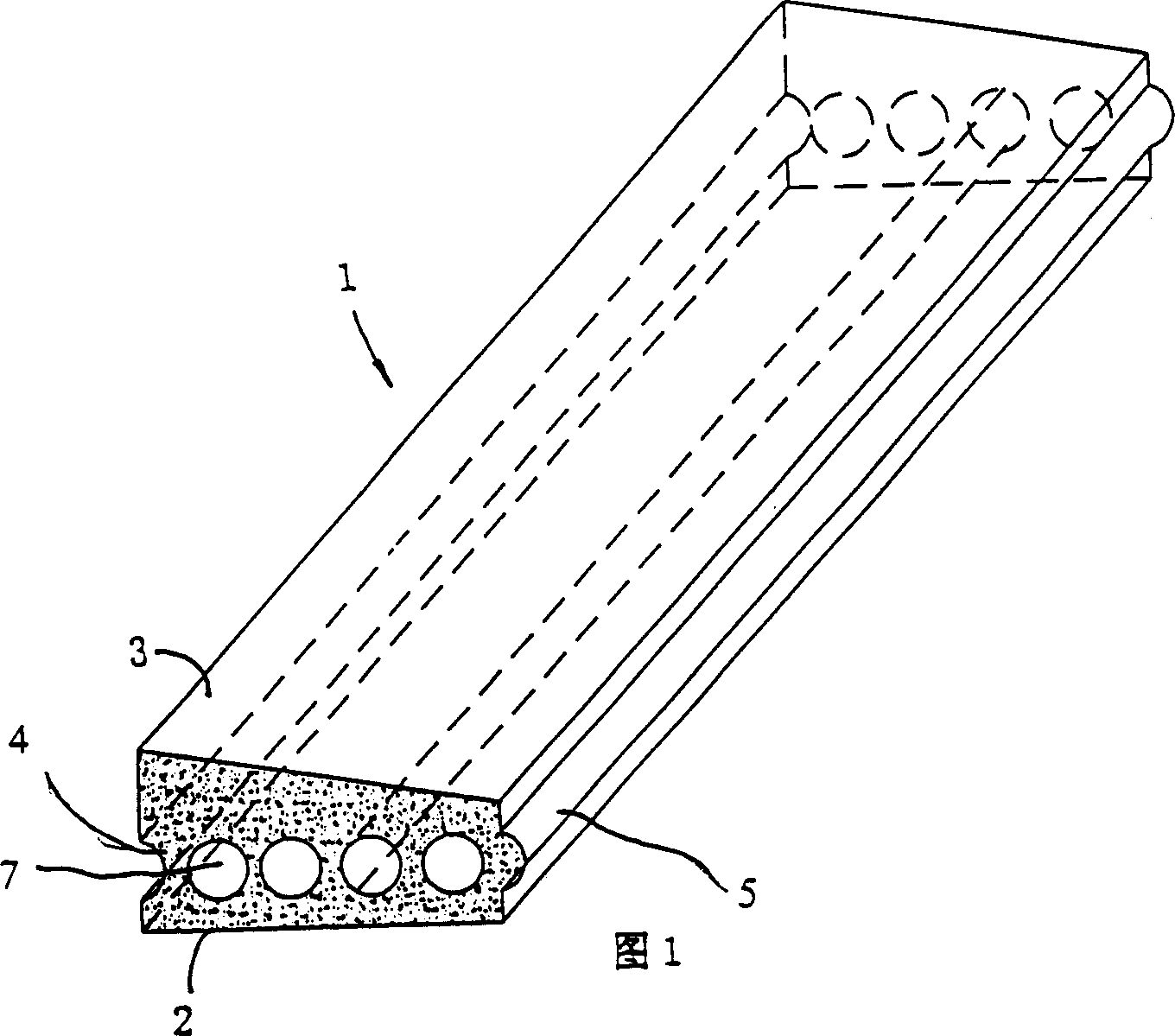

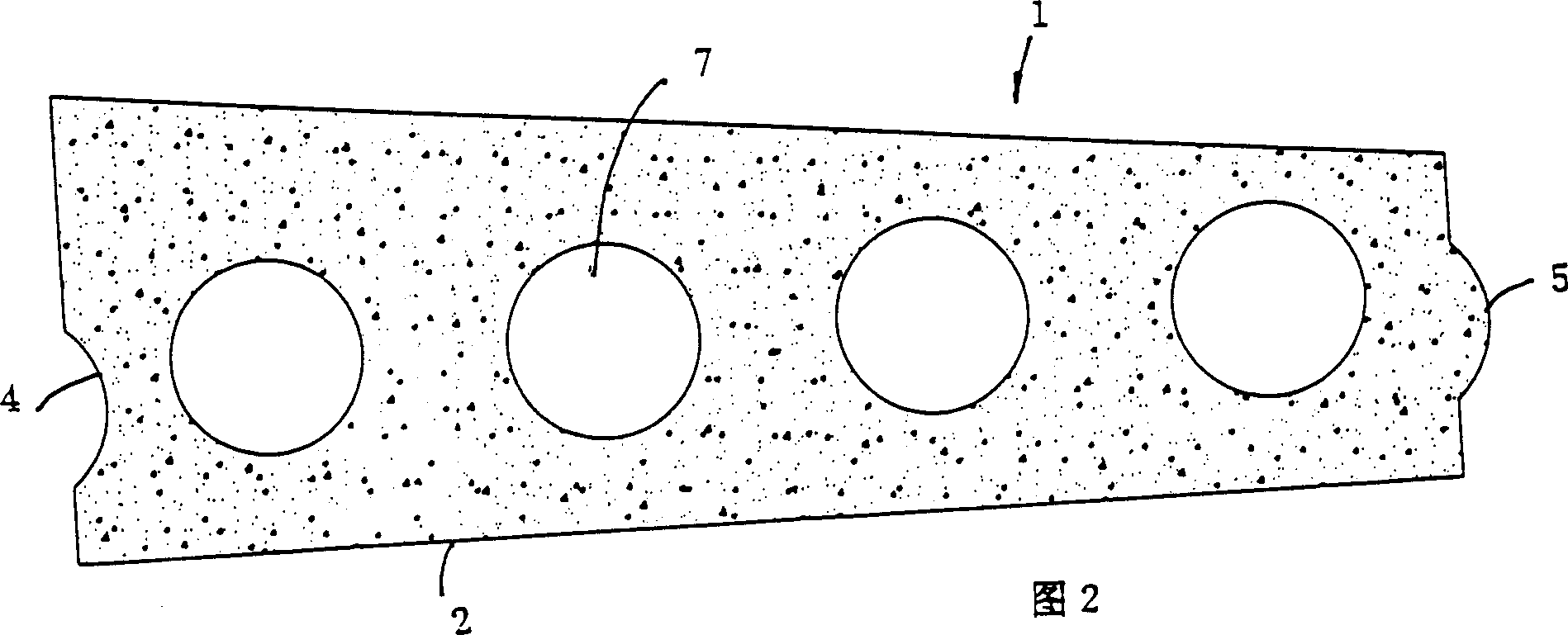

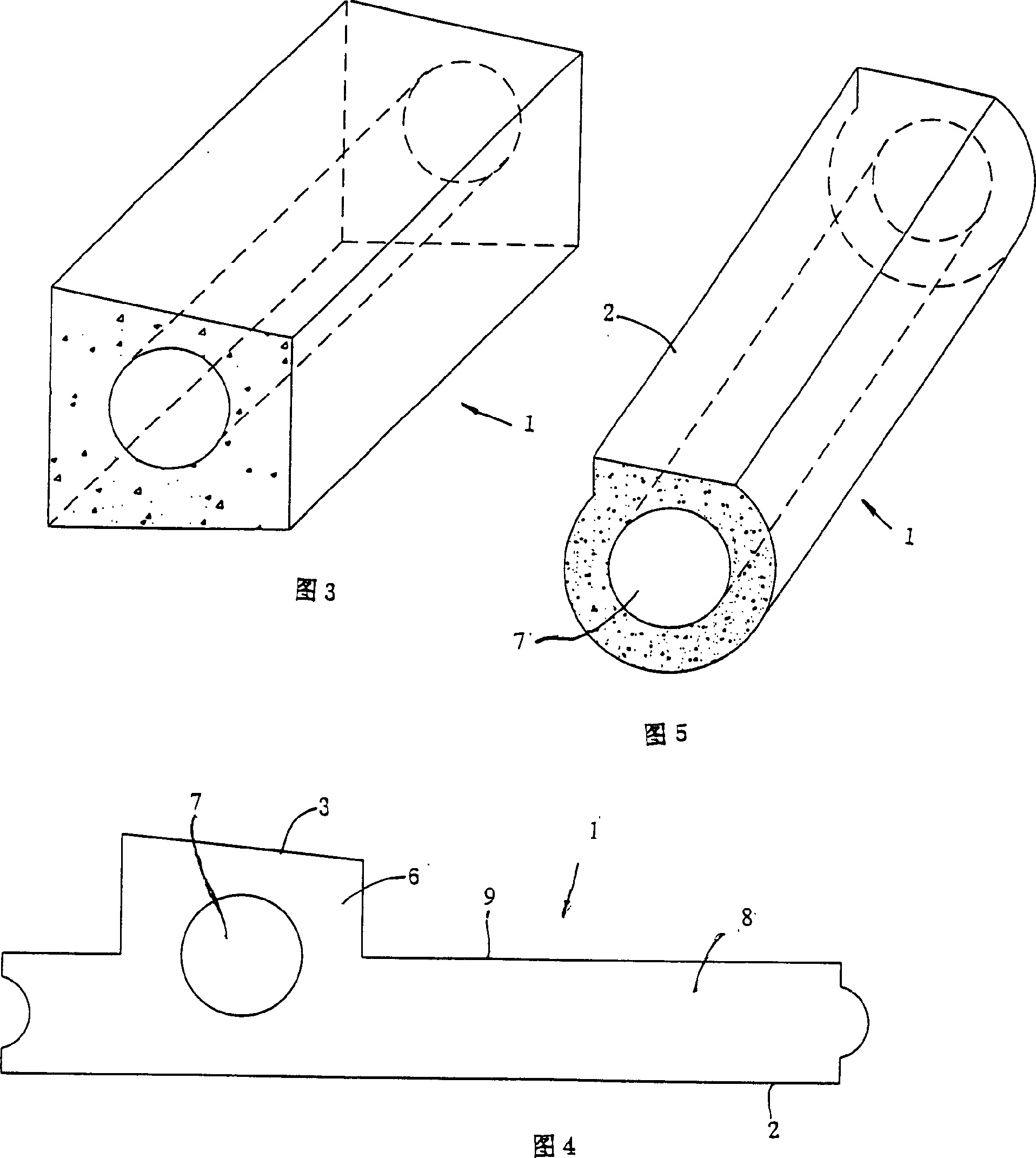

[0017] Fig. 1,2 is the perspective view and the sectional view of the first embodiment of the environment-friendly roof prefabricated part of the present invention that replaces wood products, as shown in Fig. (not shown in the figure) and the concrete module 1 of lightening hole 7, wherein the cross-sectional shape of concrete module 1 is a right-angled trapezoid, and it comprises the bottom surface 2 that is placed on the adjacent load-bearing wall of building and the top that is opposite to it The surface 3 and the bottom surface 2 are horizontal, and the top surface 3 is inclined relative to the bottom surface 2. A concave stop 4 and a convex stop 5 are respectively provided on a surface adjacent to the bottom surface 2 and the surface opposite to the surface. The cross section of the module of the first embodiment of the present invention is trapezoidal.

[0018] Fig. 3 is a perspective view of a second embodiment of an environmentally friendly roof prefabricated part rep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com