Hydraulic switches track-lifting and shifting machine

A track switch and turnout technology, which is applied to roads, tracks, and track laying, can solve problems such as low operating efficiency, large manpower required, and small amount of track lifting, and achieve low operating efficiency, manpower saving, and cost reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

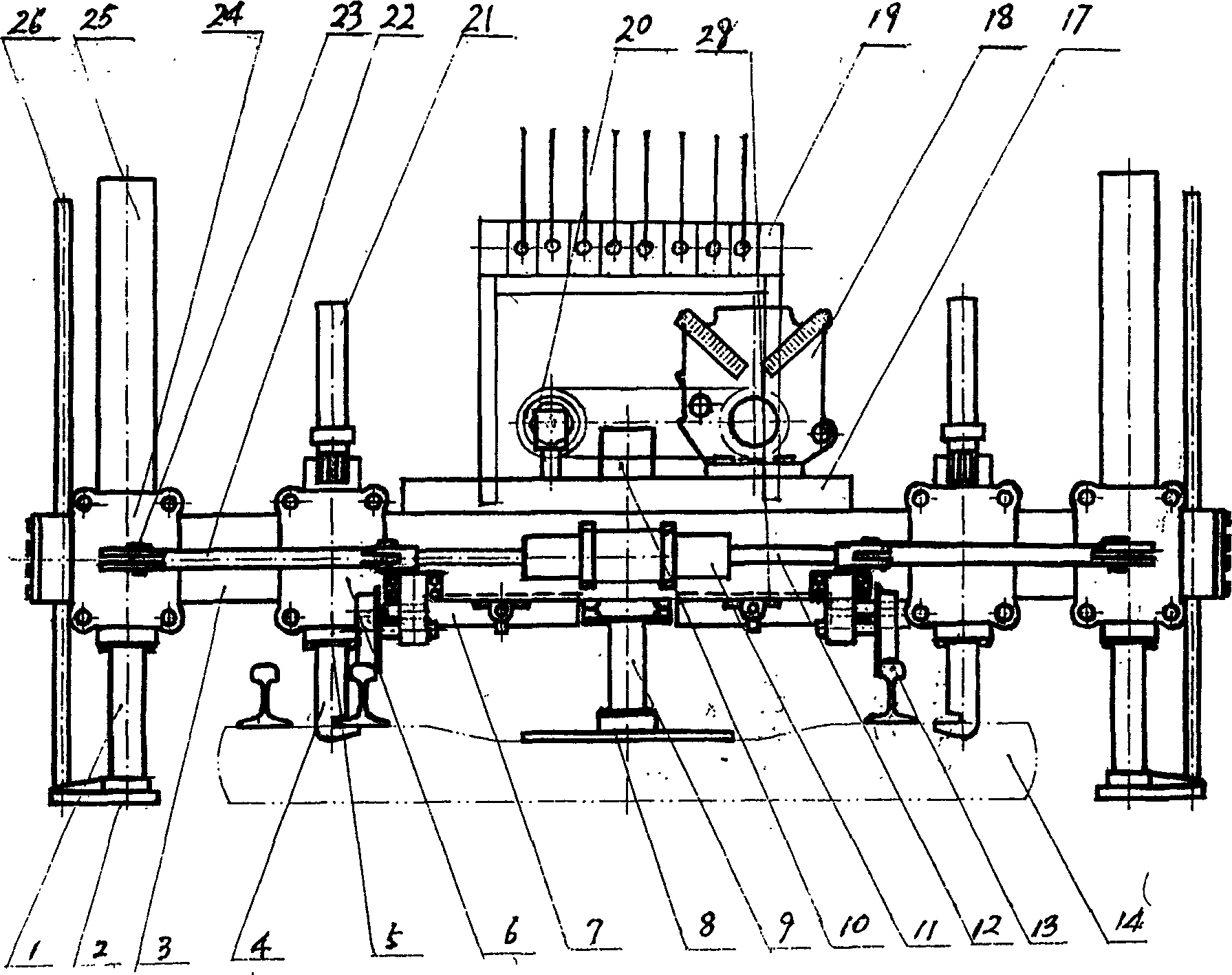

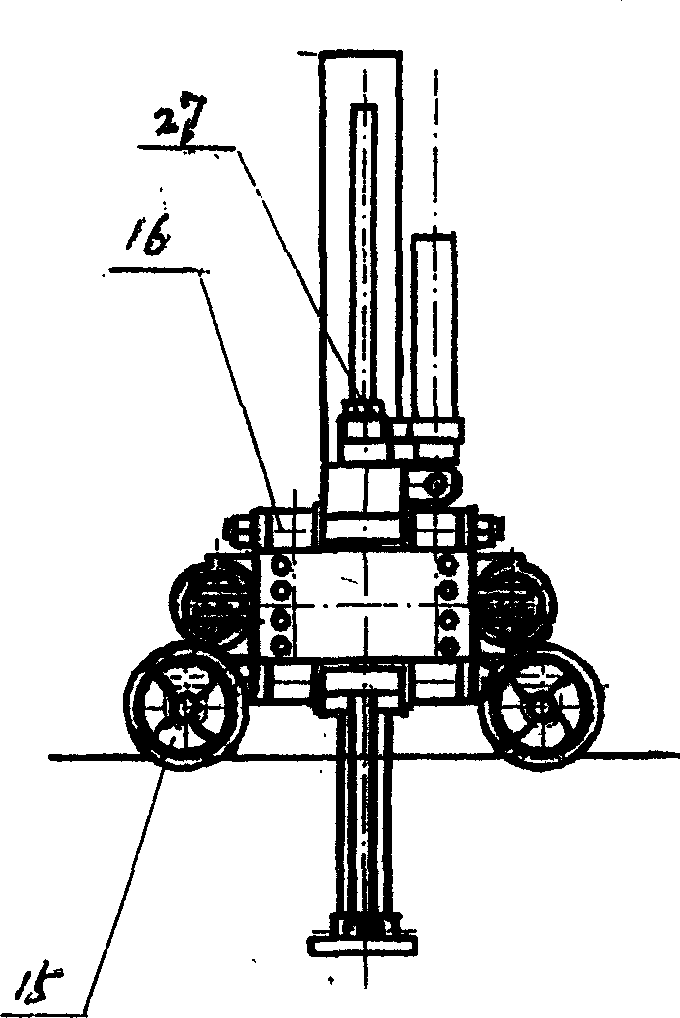

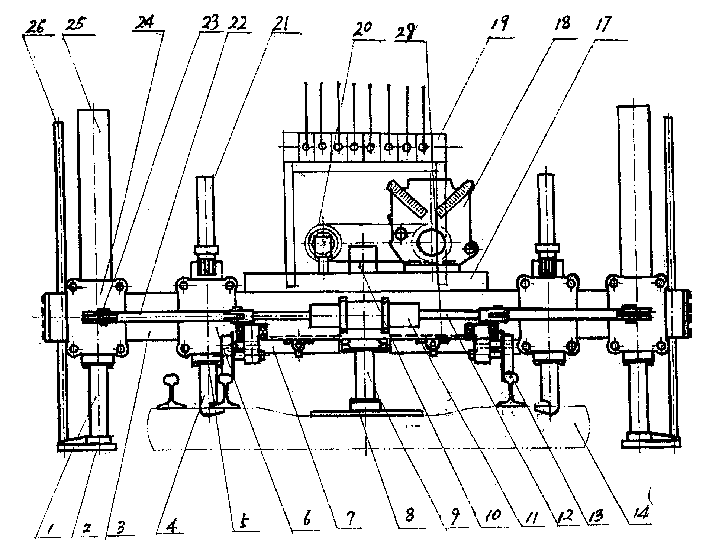

[0022] The working principle of this machine is: when the hydraulic lifting track machine is working, the gasoline engine (18) drives the hydraulic gear oil pump (20) through the belt to generate high-pressure oil, and the multi-way reversing valve (19) controls the hooking rail device, and hooks the rail tightly. Then make the upper chamber of the lifting oil cylinder (25) full of pressure oil, the lifting support seat moves downward, and the ballast is pressed to lift the rail (13) and the sleeper (14) to the specified height with the reaction force, and the lifting operation is completed. . When it is necessary to dial the track, move the track dial handle of the multi-way reversing valve (19) when the sleeper (14) and the steel rail (13) are lifted, so that the horizontal track track oil cylinder (11) and the piston rod (12) are retracted. Connect the track rolling bracket (24) in the track lifting device through the pull rod (22), forcing the body to drive the rail hook d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com