Novel process for producing calcium nitrite

A technology of calcium nitrite and a new process is applied in the field of industrial production of calcium nitrite to achieve the effects of shortening the process flow, improving the reaction efficiency and improving the reaction speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

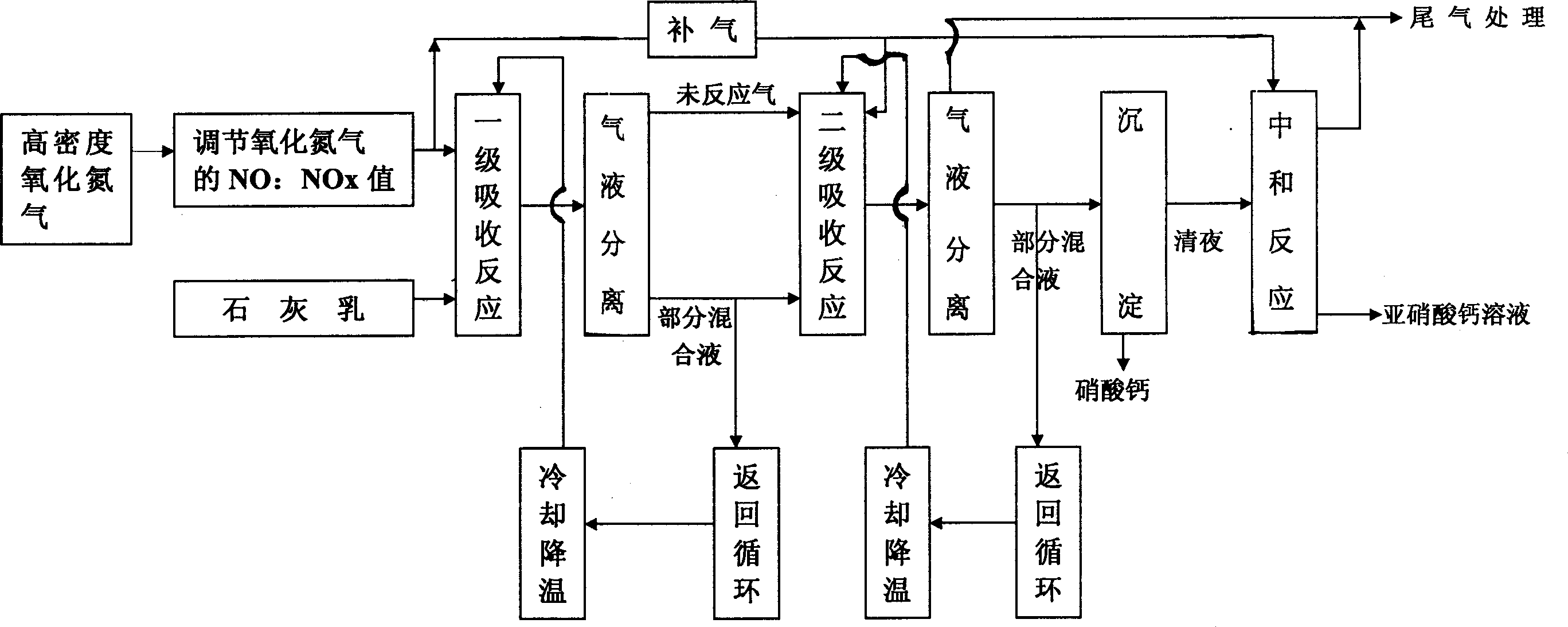

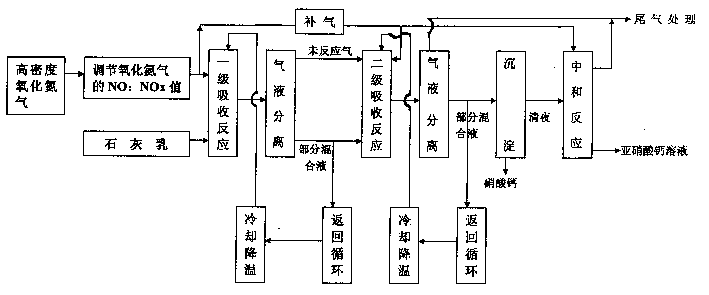

Method used

Image

Examples

Embodiment Construction

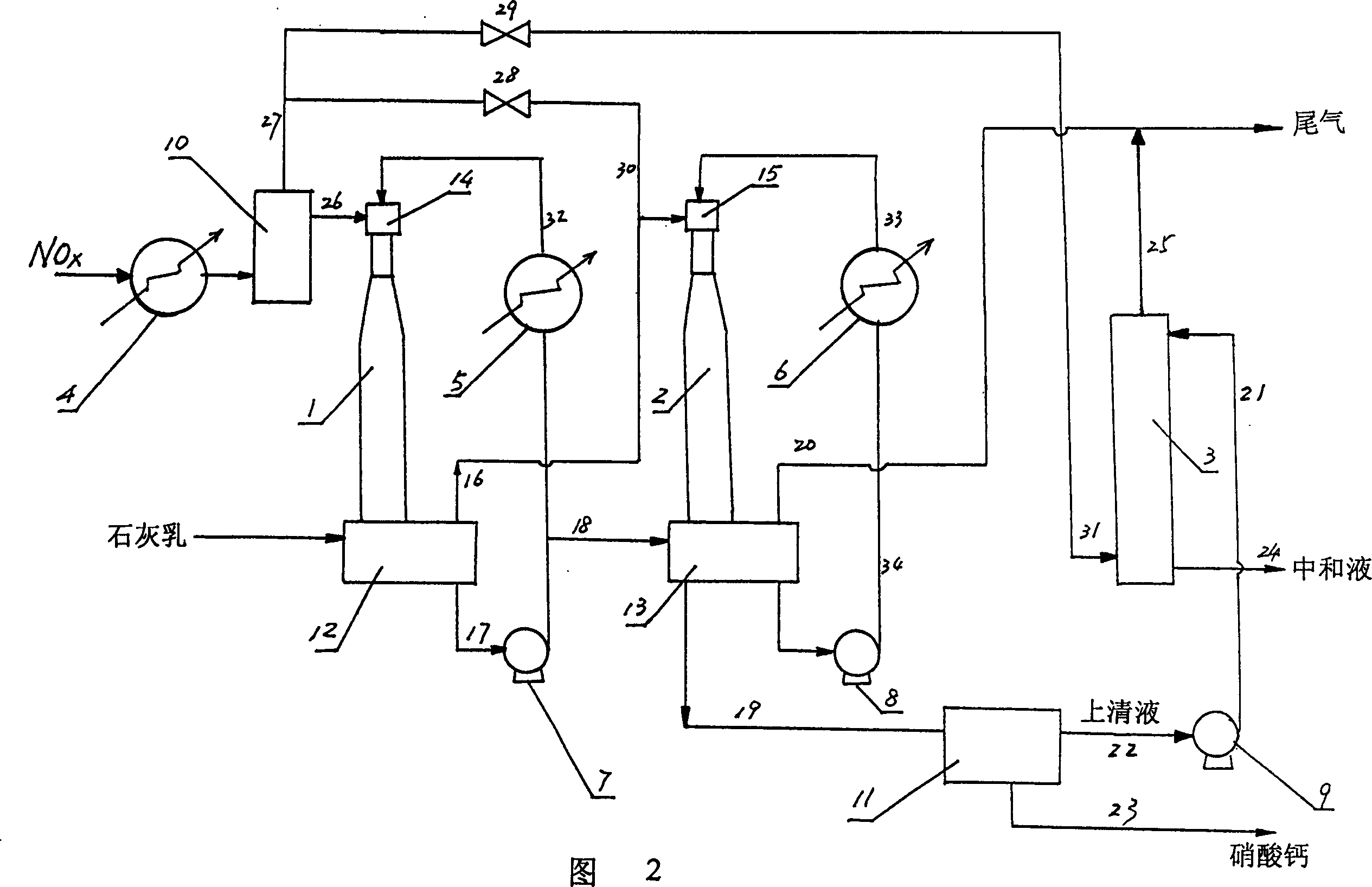

[0012] The process equipment of the present invention comprises a first stage absorption tower 1, a second stage absorption tower 2, a settling tank 11 and a neutralization tower 3, the bottoms of the absorption towers 1 and 2 are respectively separators 12, 13, and the tops are respectively injectors 14, 15, the first-stage absorption tower 1 is connected to the top ejector 15 of the second-stage absorption tower 2 through a pipe 16 on the bottom separator 12, and the second pipe 17 on the separator 12 , is connected to the separator 13 at the bottom of the second-stage absorption tower 2 through the circulation pressure pump 7 and its output pipe 18, a pipe 19 at the bottom of the second-stage absorption tower 2 is connected to the sedimentation tank 11, and the other pipe is the tail gas discharge main pipe 20. There is a pipeline 21 on the top of the neutralization tower 3, which is connected to the supernatant output pipe 22 of the sedimentation tank 11 through the pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com