Device and method for separating threads out of a thread layer

A technology for separating and warping yarns, which is used in auxiliary equipment for weaving, textiles, textiles and papermaking, etc., and can solve the problems of adding or being pulled out of warp yarn layers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

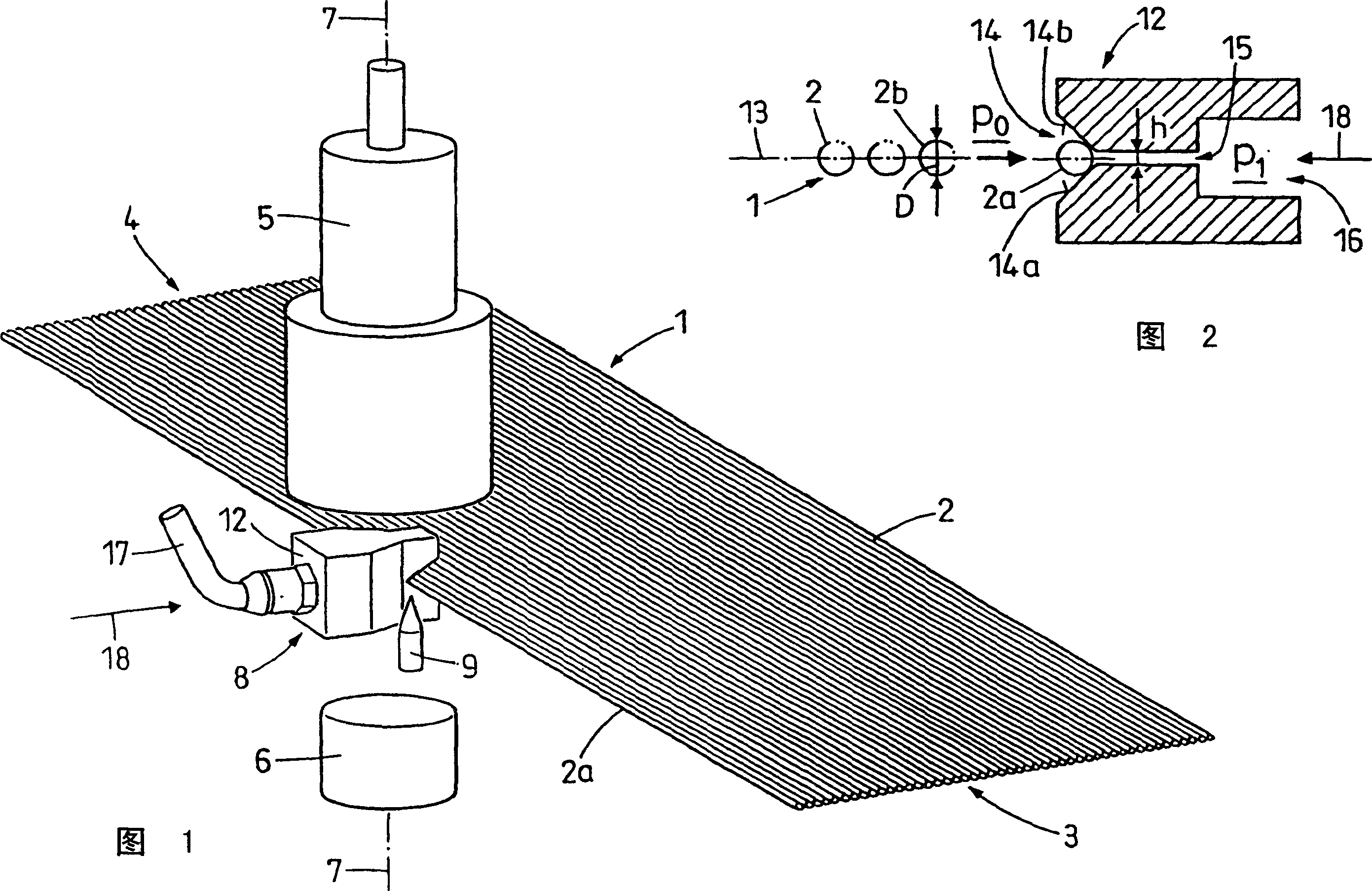

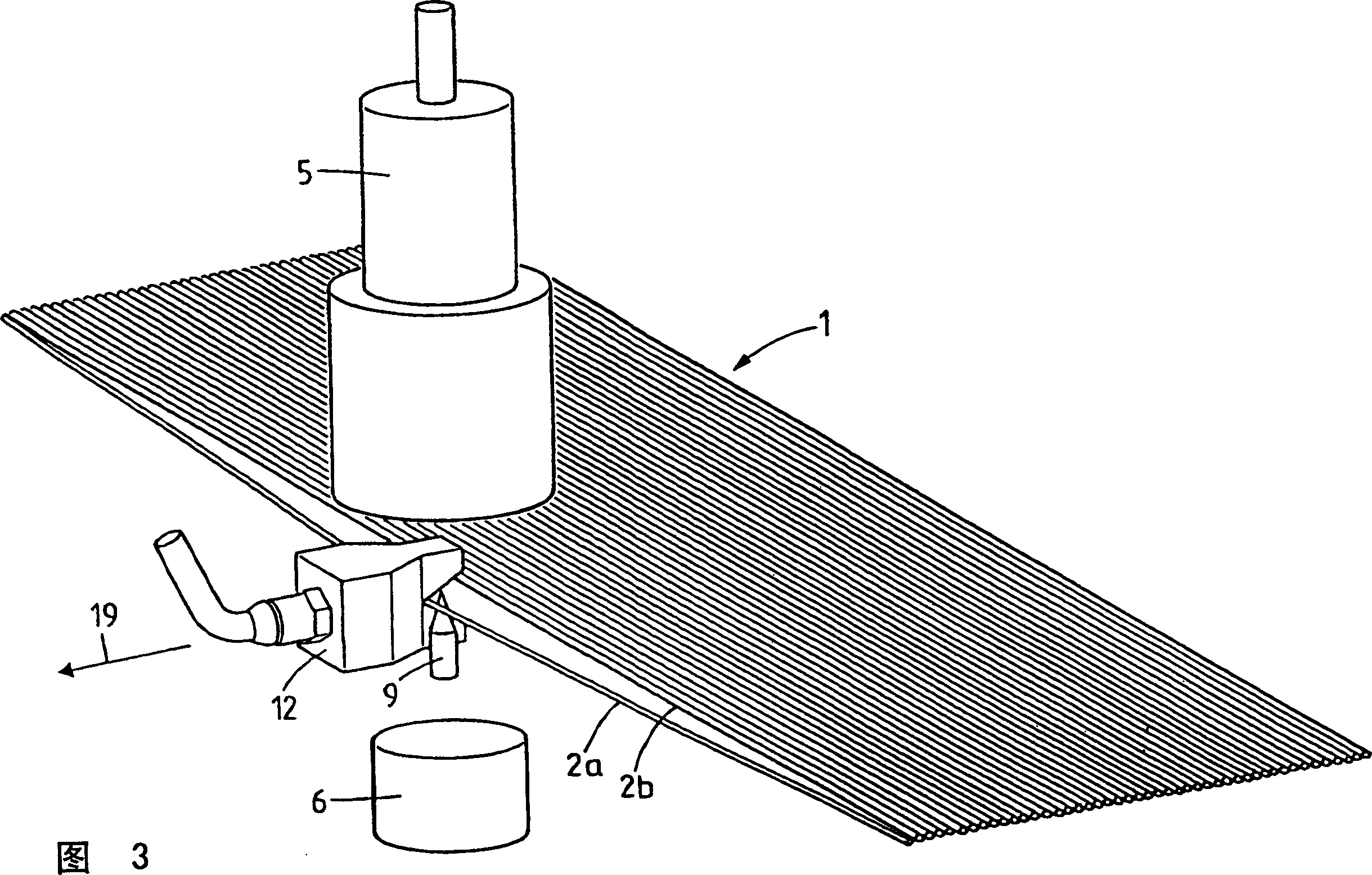

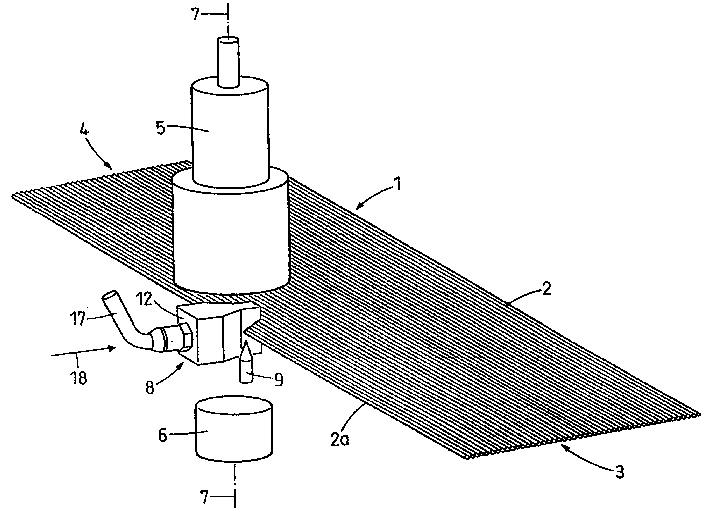

[0021] Fig. 1 shows a layer 1 of warp yarns, which has a plurality of yarns 2 of essentially the same length and extending parallel to one another, said yarns being clamped at both ends 3, 4 respectively in a suitable clamping device not shown tight. The continuous yarns 2 are ideally spaced at the same distance from one another, but they can also be spaced differently without affecting the functionality of the invention. Therefore, these yarns 2 all lie in one plane, the plane of the warp layer. Warp yarn layer 1 does not contain warp dividing elements.

[0022] Fig. 1 also shows a video camera 5 placed above the warp layer plane and a light source 6 (such as a light emitting diode) below the warp layer plane, which all belong to an optical detection device. The camera 5 and the light source 6 are on the same optical axis 7, which is at least substantially perpendicular to the plane of the warp layer.

[0023] A suction device 8 is arranged between the camera 5 and the lig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com