Compacting purified air gas storage chamber and cylinder structure

A technology for purifying air and air storage chamber, applied in the directions of cylinders, cylinder heads, engine components, etc., can solve problems such as heavy volume, and achieve the effects of reducing manufacturing costs, reducing overall weight, and improving overall rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

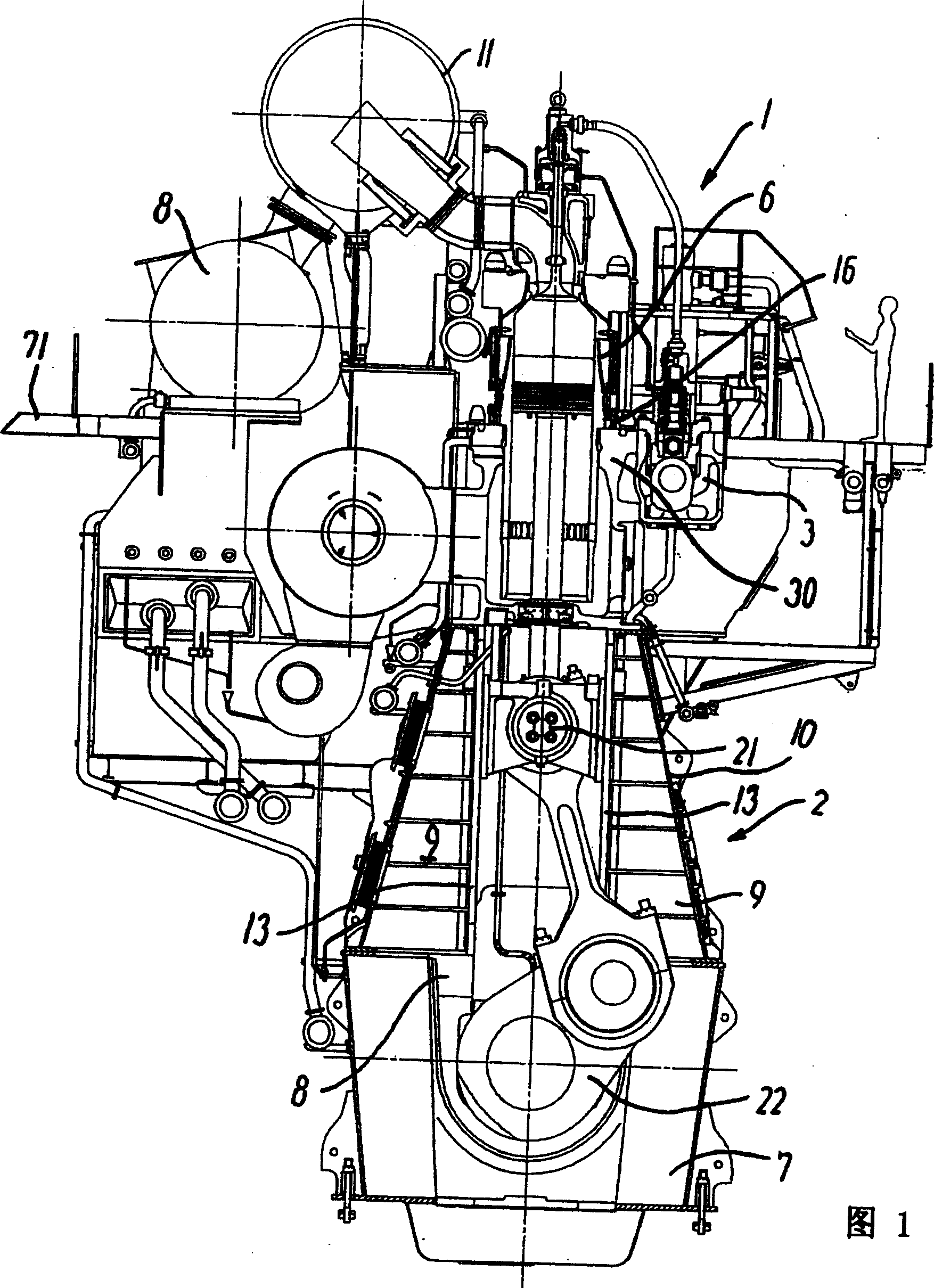

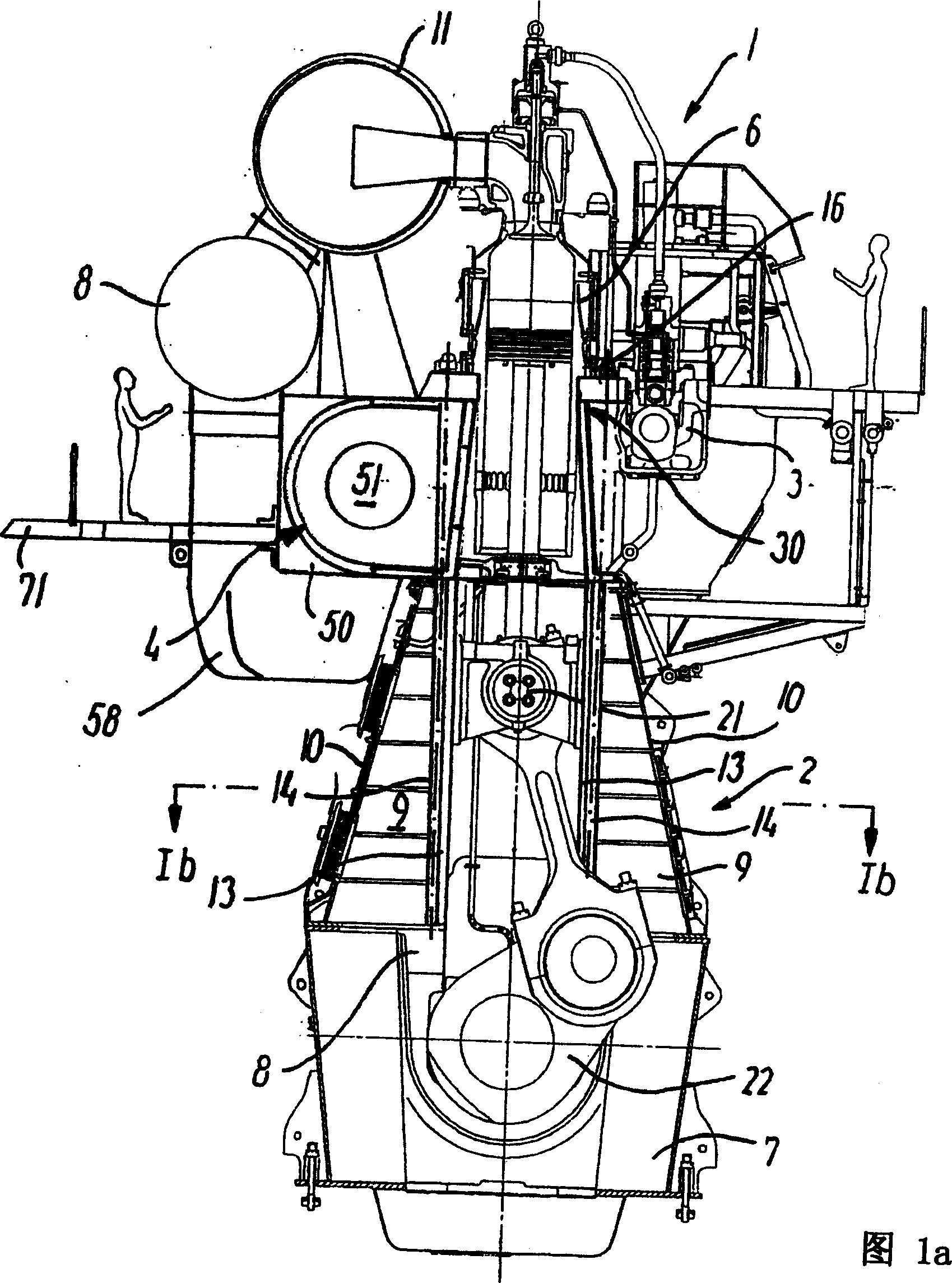

[0035] In the following detailed description, the present invention will be described by way of preferred embodiments. Figure 1 discloses an existing engine which is taller and wider than the engine of the present invention.

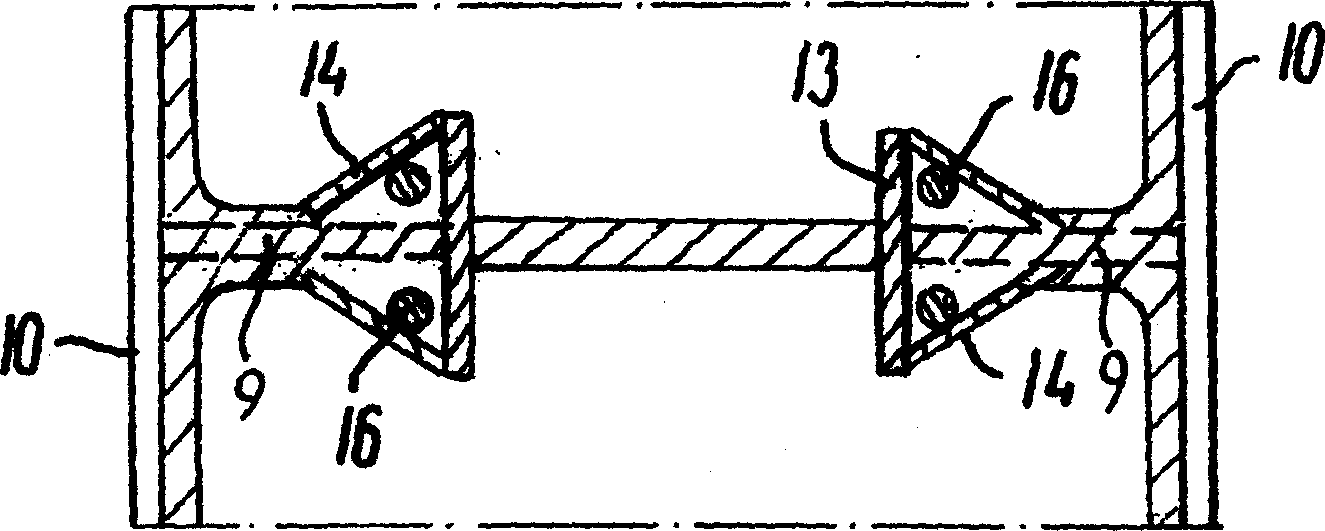

[0036] FIG. 1 a discloses a large 12-cylinder two-stroke direct-flow purified diesel engine 1 arranged on a foundation 7 with main bearings for a crankshaft 22 . For ease of production, the base 7 is divided into several sections of suitable size. It consists of high-quality welded elongated channels and welded beams with cast steel bearing supports. The welded A-shaped crankcase structure 2 is installed on the base 7 . The crankcase structure is arranged between each cylinder, on which there are ribs arranged in the form of transverse plates 9, which are interconnected with the longitudinally extending outer wall 10 of the crankcase structure 2, and the transverse plates 9 are formed from the A-shaped crankshaft The top of the box structure 2 extends...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com