Lens, combination lens and its mfg. method, optical pickup

A technology of combining lenses and manufacturing methods, applied in the direction of beam guiding devices, optics, lenses, etc., capable of solving problems such as difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

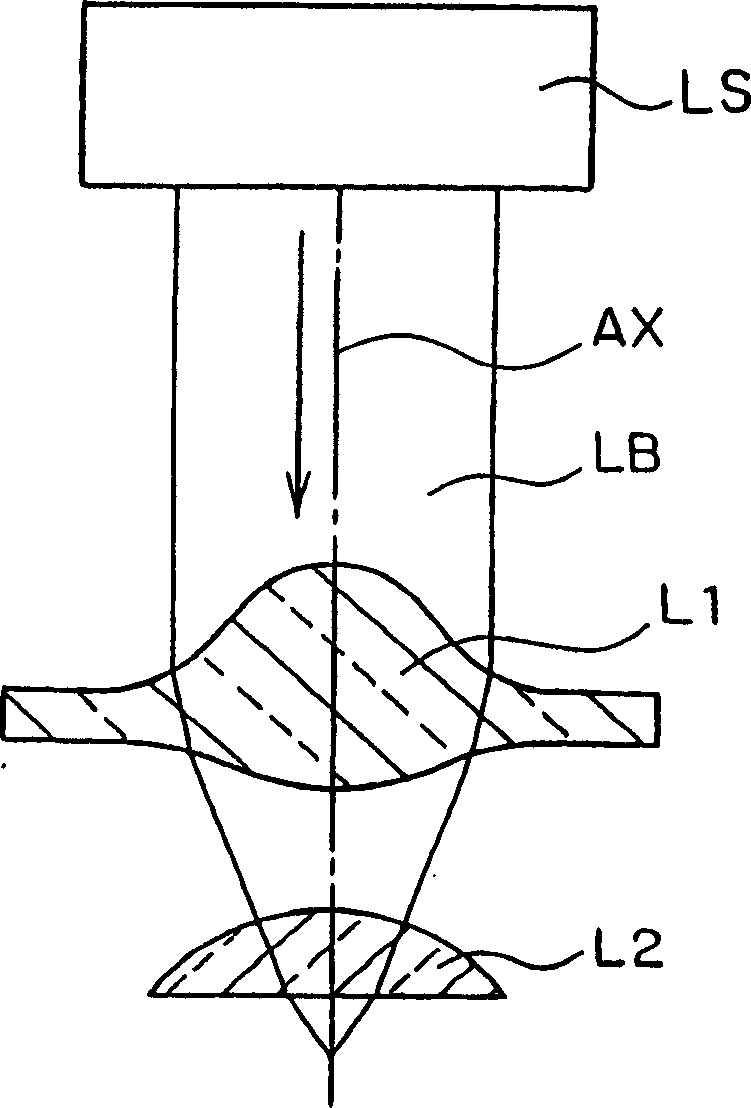

[0099] FIG. 9 is a cross-sectional view showing a schematic configuration of a combined lens (SIL) according to the present embodiment. The SIL is composed of a first convex lens L1 and a second convex lens L2.

[0100] 10A is a perspective view of the first convex lens; FIG. 10B is a perspective view of the second convex lens.

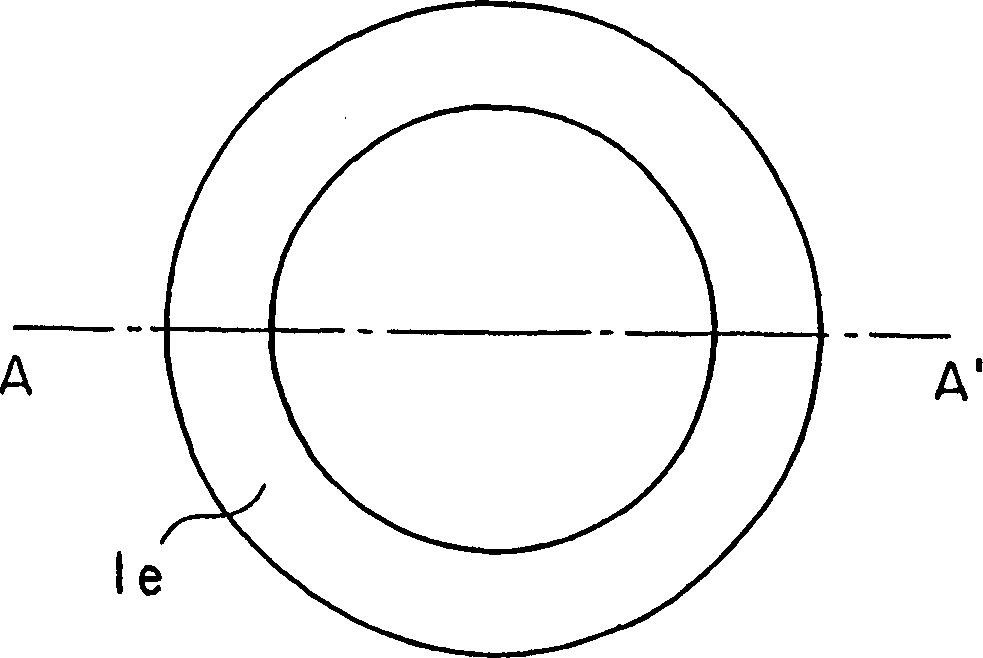

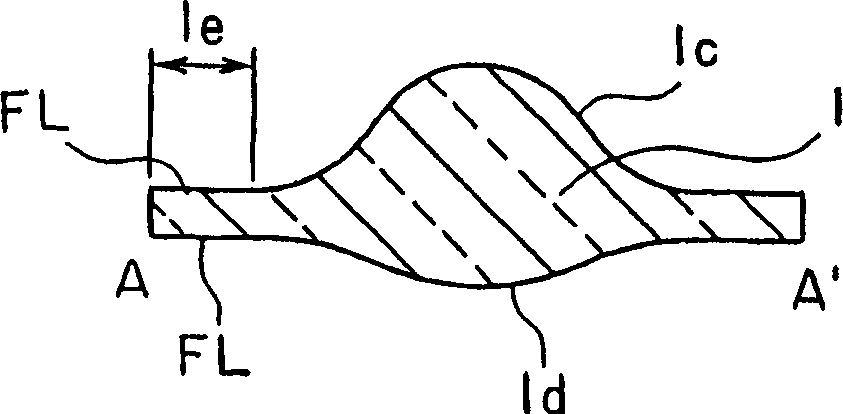

[0101] The first convex lens L1 is composed of the surface of a concave portion 1a with a convex bottom surface on the upper surface of the lens base 1 made of optical materials such as glass and the lower surface of the lens base 1, and the upper surface S of the lens base 1 except for the portion of the concave portion 1a. D and below S A are respectively the planes that should be the datum planes.

[0102] On the other hand, the second convex lens L2 is formed by embedding a material having a higher refractive index than the lens base 2 in a concave portion 2b provided on the lower surface of the lens base 2 made of an optical material such as gl...

Embodiment approach 2

[0124] FIG. 14 is a schematic configuration diagram of an optical pickup device as a main part of an optical disc device according to this embodiment.

[0125] For example, for an optical disk D rotationally driven by a spindle motor SM, a laser diode LD, a collimator C, a 1 / 2 wavelength plate HWP, a beam splitter BS, a 1 / 4 wavelength plate QWP, and an objective lens equipped with an actuator AC The SIL ( L1 , L2 ), the optical lens SL for servo and RF, the first photodiode PD1 , the lens ML for monitoring, and the second photodiode PD2 are arranged at respective predetermined positions.

[0126] The laser light L emitted from the laser diode LD passes through the 1 / 2 wavelength plate HWP after passing through the collimator to become parallel light, and then enters the beam splitter BS.

[0127] In the beam splitter BS, the incident light is partially removed and passes through it, passes through the 1 / 4 wavelength plate QWP, focuses the SIL of the combined lens related to Em...

Embodiment approach 3

[0136] FIG. 15 is a cross-sectional view showing a schematic configuration of a combined lens (SIL) according to this embodiment. It has substantially the same configuration as the combination lens SIL according to Embodiment 1, and is composed of a first convex lens L1 and a second convex lens L2 .

[0137] 16A is a perspective view of the first convex lens; FIG. 16B is a perspective view of the second convex lens.

[0138] The first convex lens L1 is composed of the surface of the convex portion 1a' provided on the upper surface of the lens base 1 made of optical materials such as glass and the lower surface of the lens base 1. The lower surface S of the lens base 1 A becomes the plane that should be the datum.

[0139] On the other hand, the second convex lens L2 is formed by embedding a material having a higher refractive index than the lens base 2 in a concave portion 2b provided on the lower surface of the lens base 2 made of an optical material such as glass.

[0140]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com