Hydraulic transformer

A hydraulic transformer and distribution plate technology, applied in the field of hydraulic transformers, can solve problems such as hydraulic transformer size reduction, increase in hydraulic transformer complexity, oil energy loss, etc., to expand the range of voltage regulation ratio and solve oil throttling loss , Noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

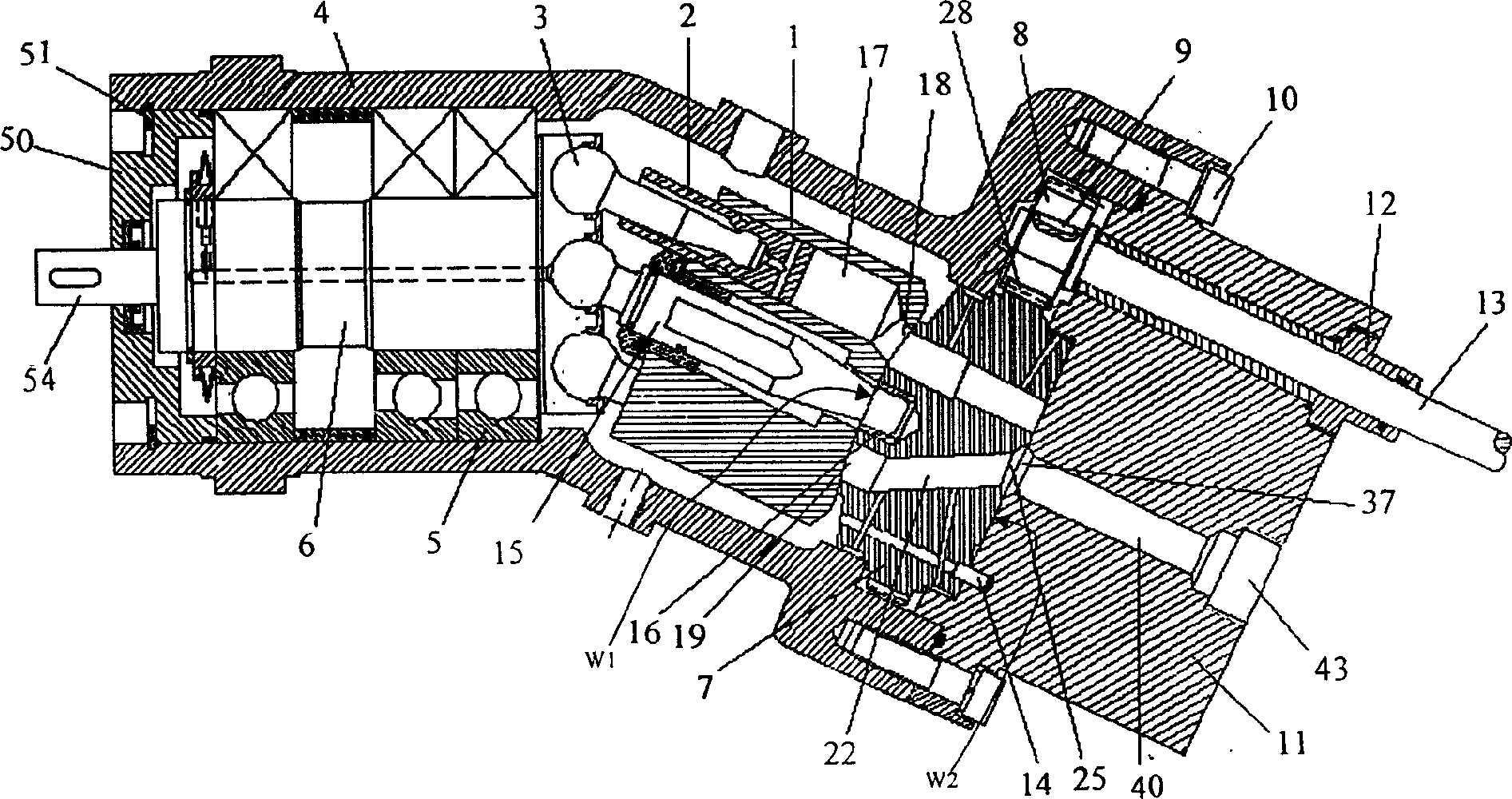

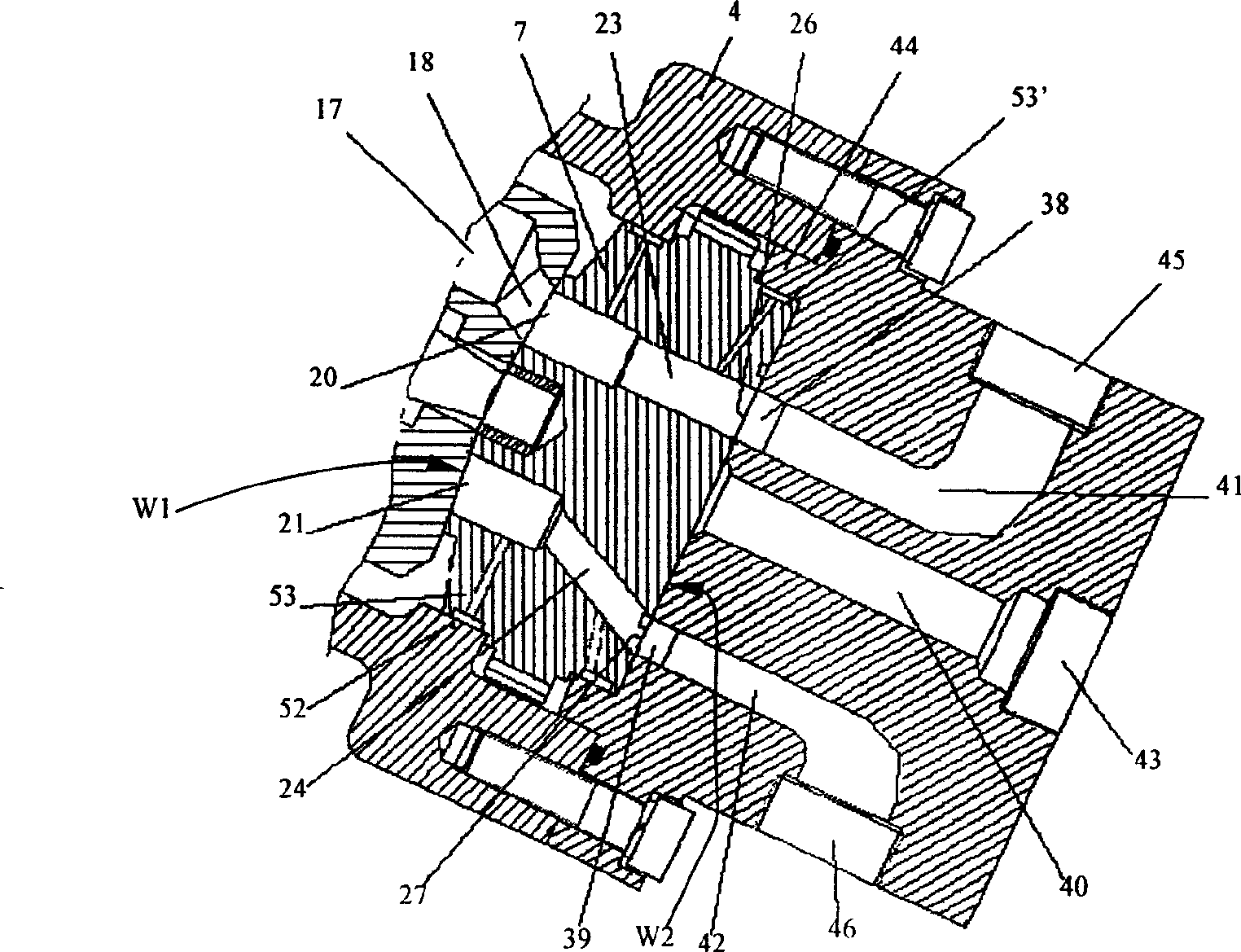

[0031] Such as Figure 1 to Figure 9 As shown, the present invention includes:

[0032]1) One end of the inclined-axis type casing 4 is connected to the rear end cover 11, and the other end of the inclined-axis type casing 4 is connected to the front end cover 50 to form a closed cavity of the inclined-axis type hydraulic transformer, which is mounted on the inclined-axis One end of the rotating shaft 6 in the type housing 4 is connected to the output end 54 installed on the front end cover 50, the axis of the central shaft 15 intersects the axis of the rotating shaft 6, and the flow plate 7 is mounted on the cylinder body 1 and the rear end cover 11 Between; one end of the central shaft 15 on the cylinder body 1 is hinged on one end of the rotating shaft 6, and the other end of the central shaft 15 is installed at the elongated hole 16 in the center of the front end of the distribution plate, and the cylinder body 1 is equipped with a plunger 2, The plunger 2 is connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com