Low-temp radiation heating slab

A low-temperature radiation and plate technology, applied in the field of building decoration, can solve the problems of complicated construction procedures and operations, high labor intensity of construction personnel, unclean construction site, etc., to achieve the effect of convenient daily maintenance, easy demolition and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

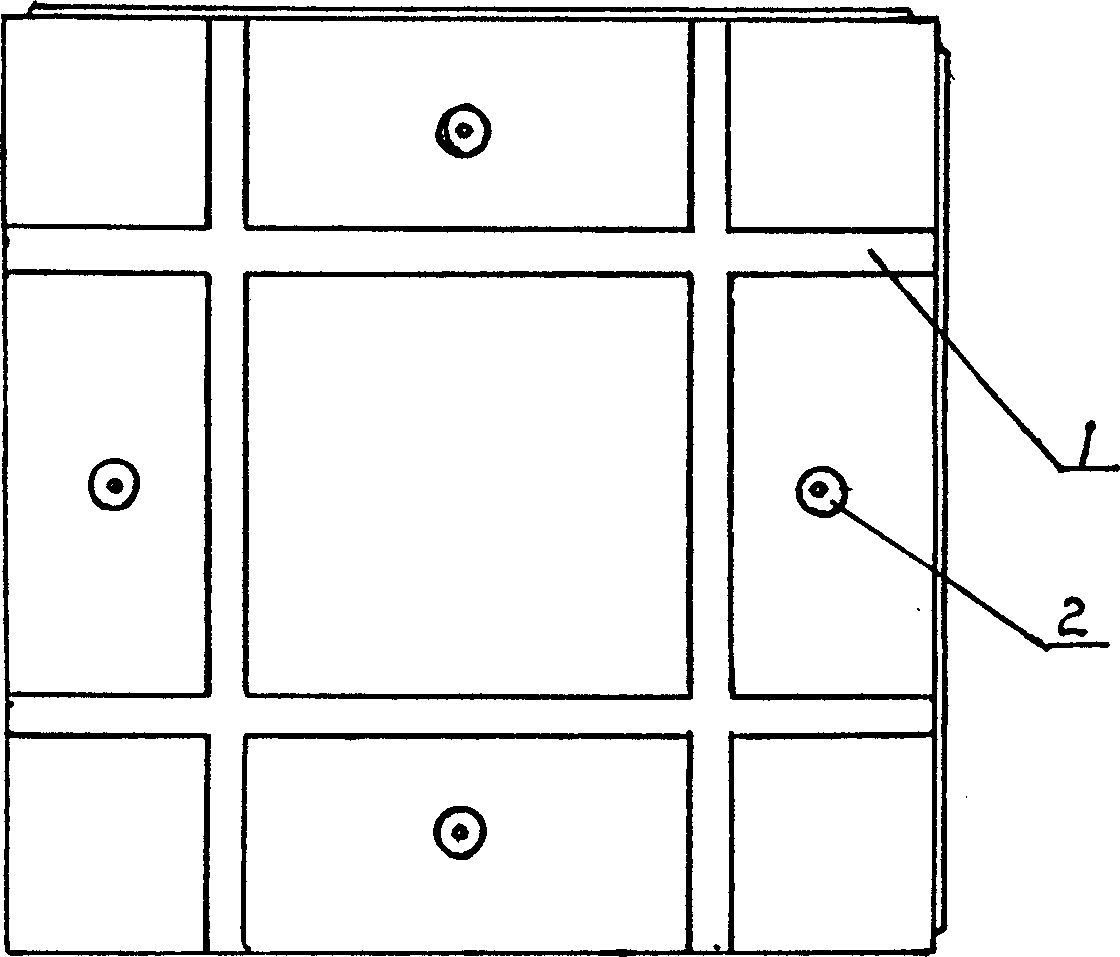

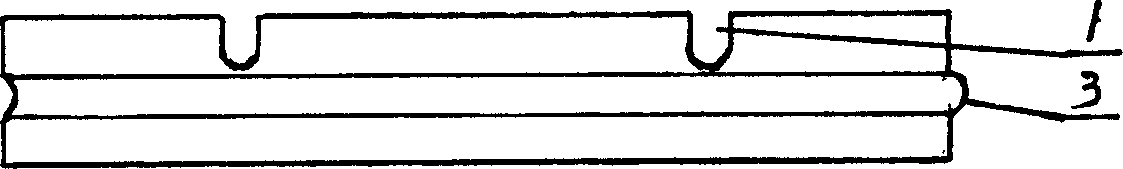

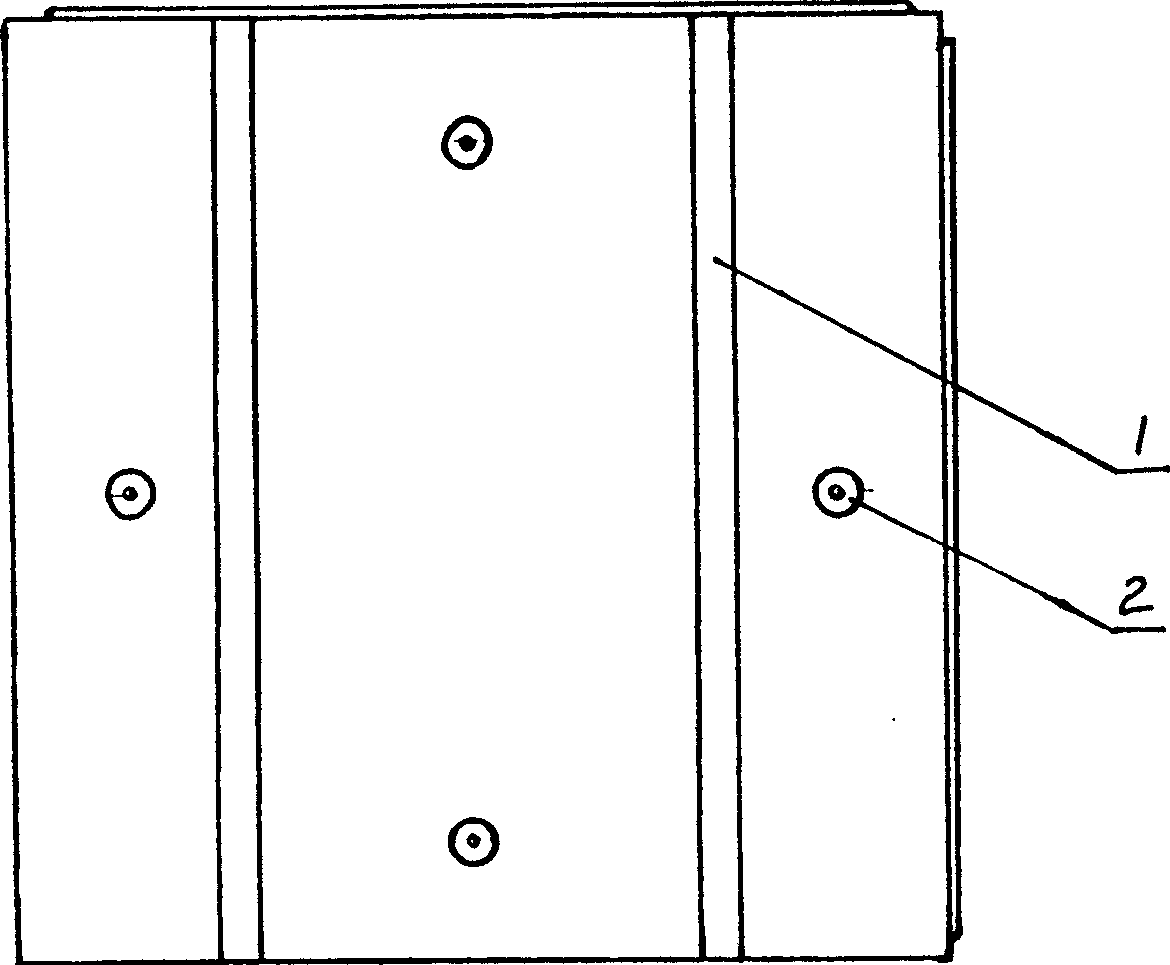

[0011] As can be seen from the accompanying drawings, the square plate grooves (1) are divided into multiple forms such as well-shaped, parallel tracks, parallel curved tracks and well-shaped intersecting and dividing lines, and fixed mounting holes (2) are evenly provided on the plates. The groove depth of the groove (1) is 10-100mm, and the groove width is 10-50mm; the thickness of the plate is 15-150mm, and there are convex and concave surfaces connected with each other around the plate; Use slotted holes and bolt connections. There are different types of grooves (1) and uniform fixing holes (2) on the plate made of mixed soil. Pipes of different varieties and specifications can be embedded in the grooves, which are used for low-temperature radiant heating of hot water floors. The plates can be assembled on the ground in a large area, and can also be assembled and fixed on the wall. It can simplify the installation procedures and complicated construction of the mixed soil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com