Sewing machine with cloth cutter

A sewing machine and cutter technology, applied in the field of sewing machines, can solve problems such as difficulty in determining the correct position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] specific implementation

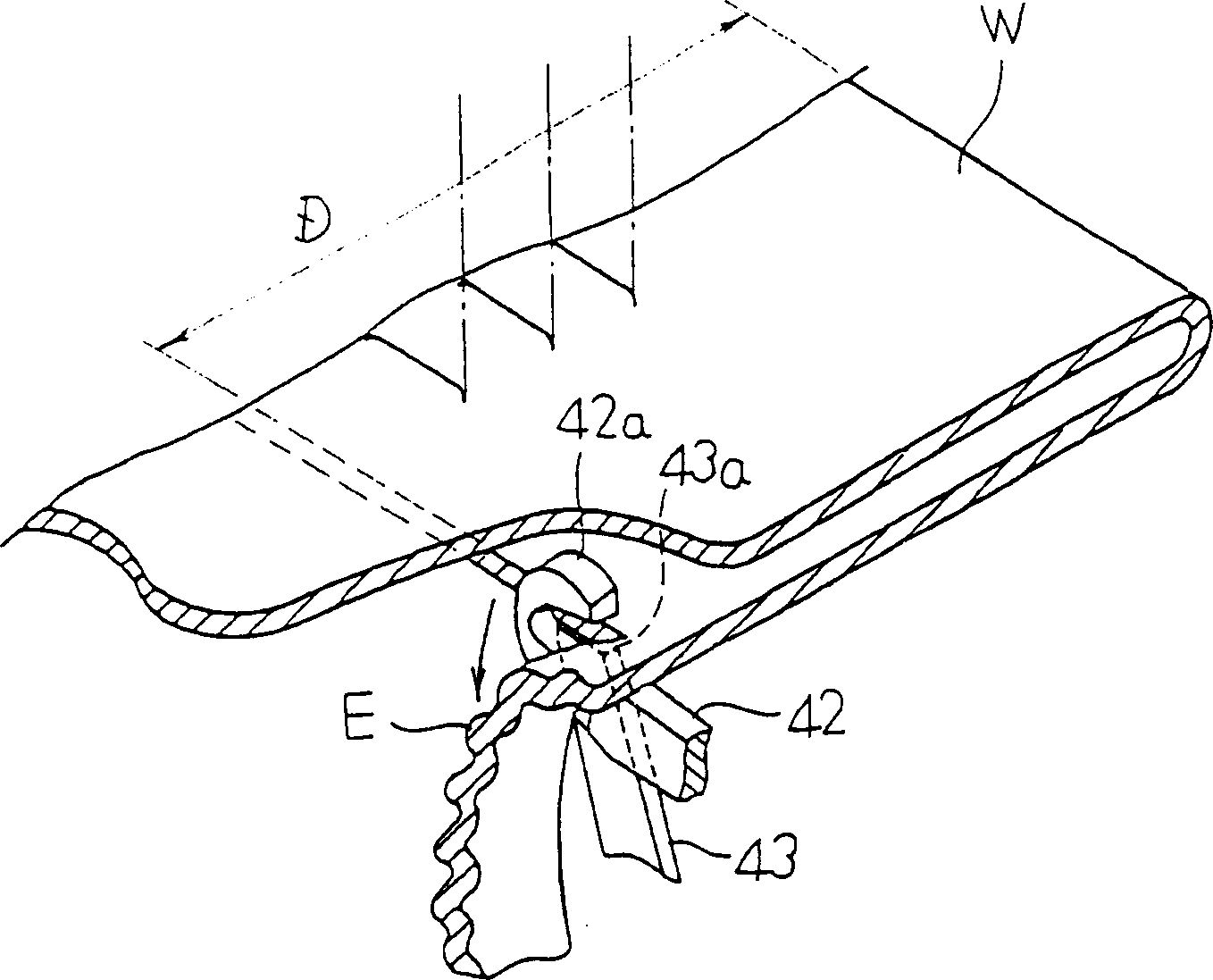

[0027] Hereinafter, the present invention will be described in detail based on drawings showing preferred embodiments. image 3 It is a perspective view of the overall structure of the sewing machine with the cutter according to the present invention.

[0028] The illustrated sewing machine is a flat seam sewing machine having a sewing machine arm A at the bottom supported by a leg part C established on the upper surface of the sewing machine bed B. As shown in FIG. A plurality of needles 1, 1 . Also, on the front end portion of the sewing machine B facing below the needles 1, 1..., a needle plate (Stitch Plate) 3 is erected, and an unillustrated looper (Looper) and a feeding mechanism are arranged on the bottom of the needle plate 3. (Feed Mechanism).

[0029] The above-mentioned needles 1, 1... are transmitted from an unshown upper shaft built in the arm of the sewing machine, and together with the above-mentioned needle bar, move up and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com