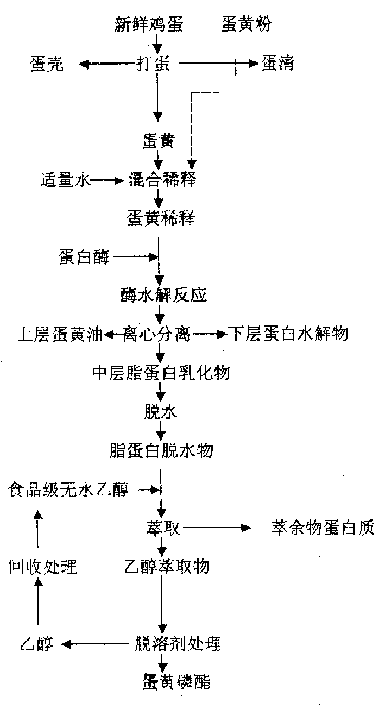

Method for extracting yolk oil by enzyme hydrolysis-solvent extraction

A technology of enzymatic hydrolysis and egg yolk, applied in the direction of fat oil/fat production, fat production, etc., can solve the problems of industrialized large-scale production constraints, achieve the effect of high total oil yield and improve economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Beat the eggs with fresh eggs to separate them, and stir them with egg yolks and water to prepare 10% (W / W) egg yolk liquid.

[0049] Add protease A of 1% (W / W) of substrate mass, perform enzymatic hydrolysis reaction at 37°C and pH7 for 2.5 hours, and then add protease B of 1.5% (W / W) substrate mass to continue enzymatic hydrolysis reaction for 2 hours.

[0050] Centrifuge at 90° C. and 3000 rpm for 15 minutes, the upper layer is the first part of neutral fat egg oil product, and the oil yield is 59%, and the lower layer protein hydrolyzate is a by-product.

[0051] Dehydrate the lipoprotein emulsion in the middle layer for 60 minutes at a vacuum degree of 0.1 MPa and a heating temperature of 50°C.

[0052] Add food-grade absolute ethanol to the dehydration mixture at a ratio of 1 g:gml, and extract at 50° C. for 50 min.

[0053] The extraction mixture is separated by filtration using analytical filter paper as a medium, and the raffinate remains on the filter paper a...

Embodiment 2

[0056] Add water and stir with egg yolk powder to prepare 10% (W / W) egg yolk liquid. The rest of the operating conditions are the same as

[0057] Example 1.

Embodiment 3

[0059] Add water and stir with egg yolk powder to prepare 10% (W / W) egg yolk liquid.

[0060] Add protease A with 2% (W / W) of the substrate mass. The hydrolysis reaction time is 3.5 hours. All the other operating conditions are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com