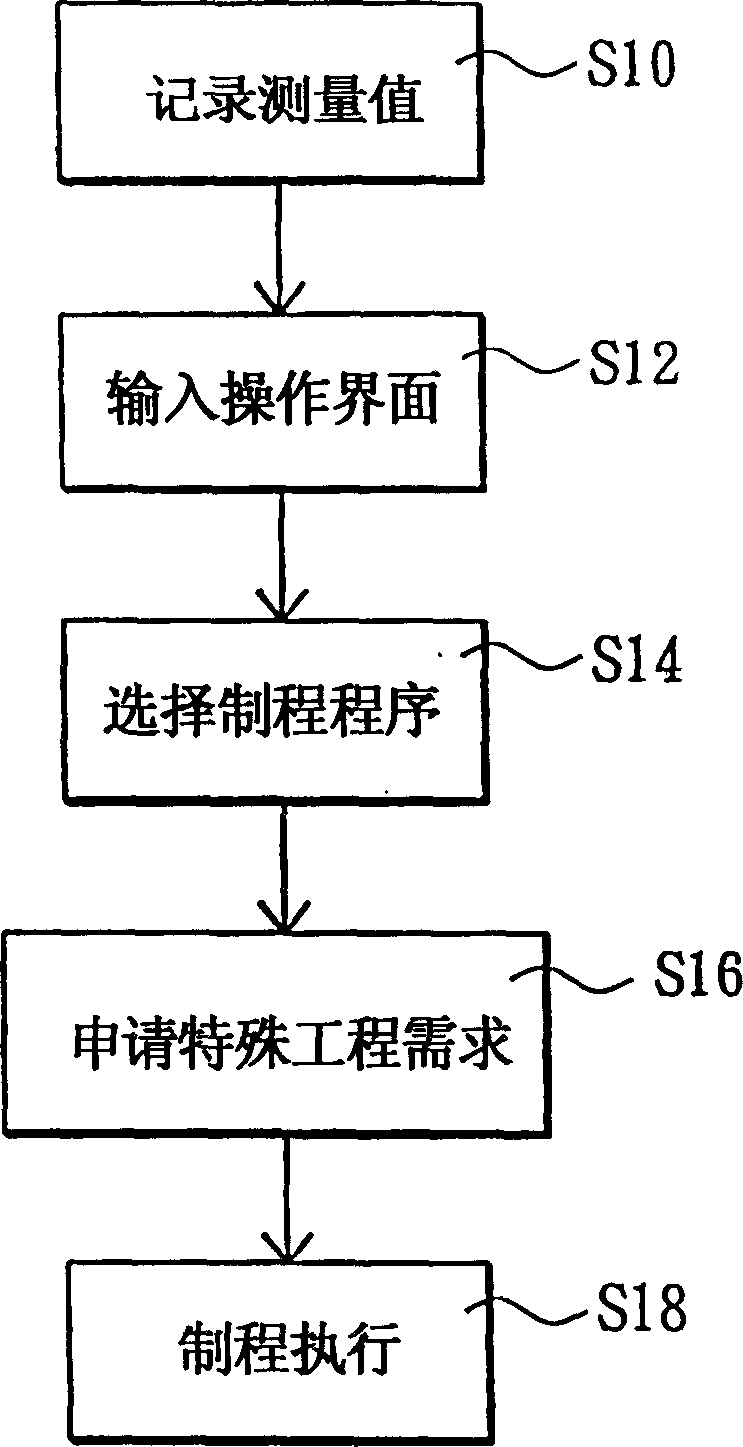

Semiconductor manufacturing system and process control method thereof

A technology for manufacturing systems and semiconductors, applied in semiconductor/solid-state device manufacturing, program control design, memory systems, etc., can solve problems such as complexity, low production efficiency, and increased manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

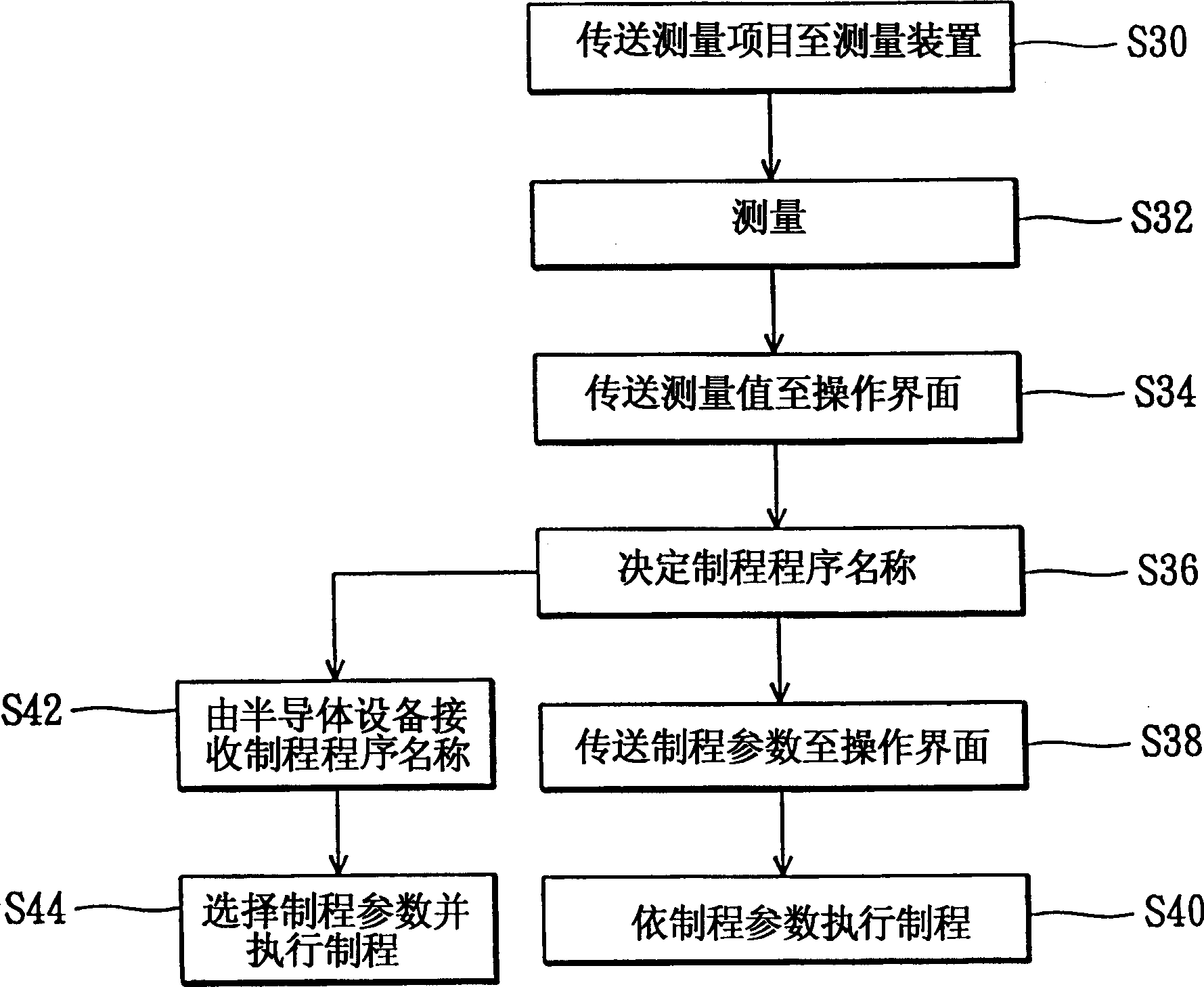

[0011] figure 2 with image 3 Respectively, a block diagram of a semiconductor manufacturing system according to an embodiment of the present invention and a flow chart of a control process program used therein.

[0012] First, in figure 2 In the illustrated embodiment, the semiconductor manufacturing system includes a data module (basic record, BR) 20 , an operation interface (operation interface, OPI) 22 , a measurement device 24 and semiconductor devices 26 and 28 . Wherein, the operation interface (OPI) 22 is associated with the data module (BR) 20, and both are included in a control system (not shown in the figure). The data module 20 has a measurement item field (not shown in the figure) and a process procedure identification field (not shown in the figure), the functions of which will be described later in this article.

[0013] In this embodiment, a measuring device 24, such as a thickness gauge, is coupled to the operation interface 22 of the control system. In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com