Method for preparing Inserted layers type nano composite material of polypropylene/montmorillonite

A nano-composite material and polypropylene technology is applied in the field of preparation of organically modified montmorillonite filled polypropylene to form intercalated nano-composite materials, and achieves the effect of good comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

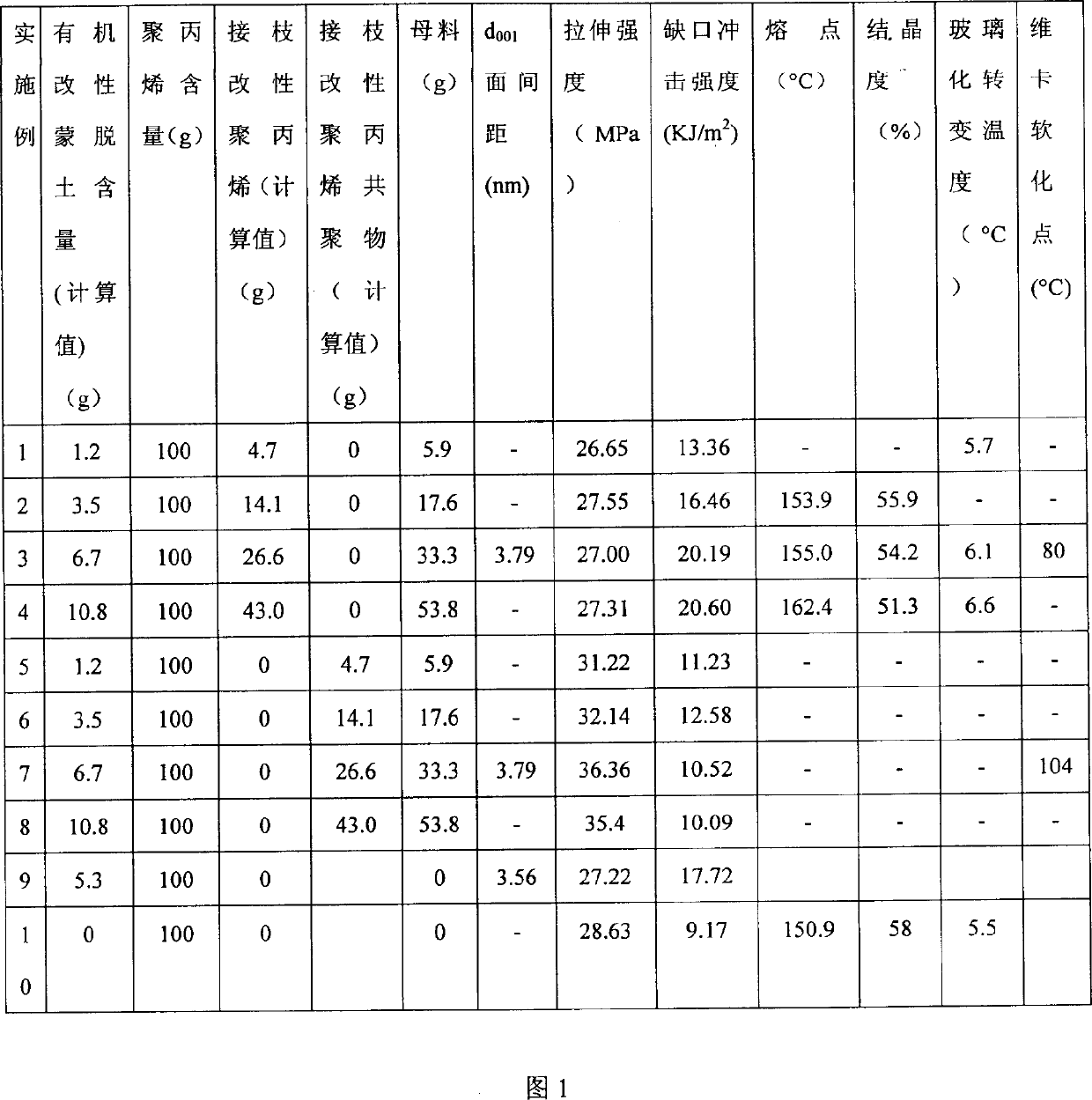

Examples

Embodiment 1

[0029] 100g polypropylene, 4.2g maleic anhydride and 0.84g dibenzoyl peroxide are blended, extruded and granulated with a twin-screw extruder, and the extrusion temperature is 160-190°C to obtain graft modified polypropylene; then 100g Graft modified polypropylene is mixed with 25g of organically modified montmorillonite, stirred with a high-speed mixer, extruded and granulated with a twin-screw extruder, and the extrusion temperature is 180-220°C to obtain a masterbatch; then 100g of polypropylene Mix 5.9 g of the masterbatch, stir with a high-speed mixer, extrude and granulate with a twin-screw extruder, and the extrusion temperature is 180-220° C. to obtain the product. Its performance is shown in Table 1.

Embodiment 2

[0031] 100g polypropylene, 1.2g maleic acid, 0.14g dicumyl peroxide, extrude and granulate with a twin-screw extruder, and the extrusion temperature is 160-190°C to obtain grafted modified polypropylene; then graft 100g Modified polypropylene is mixed with 15g of organically modified montmorillonite, stirred with a high-speed mixer, extruded and granulated with a twin-screw extruder, and the extrusion temperature is 180-220°C to obtain a masterbatch; then 100g of polypropylene 17.6g The masterbatch is mixed, stirred with a high-speed mixer, extruded and granulated with a twin-screw extruder, and the extrusion temperature is 180-220°C to obtain the product. Its performance is shown in Table 1.

Embodiment 3

[0033] 100g of polypropylene, 10g of acrylic acid, and 1.0g of dibenzoyl peroxide are blended, extruded and granulated with a twin-screw extruder, and the extrusion temperature is 160-190°C to obtain graft-modified polypropylene; Mix permanent polypropylene with 35g of organically modified montmorillonite, stir with a high-speed mixer, extrude and granulate with a twin-screw extruder, and the extrusion temperature is 180-220°C to obtain a masterbatch; then mix 100g of polypropylene with 33.3g of masterbatch Mix the materials, stir with a high-speed mixer, extrude and granulate with a twin-screw extruder, and the extrusion temperature is 180-220°C to obtain the product. Its performance is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com