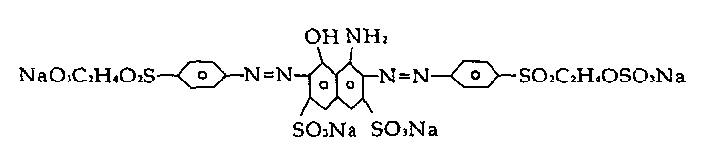

Complex color matching reactive black dye

A technology of reactive black and dyes, applied in the direction of organic dyes, etc., can solve the problems of poor lifting power and blackness, poor color brightness, and difficult washing, and achieve the effect of reducing impurities and improving blackness and color brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The preparation of a composite color-blocking reactive black dye B-BGFF of the present invention is: according to the corresponding process, p-(vinylsulfone-based sulfate) aniline is dissolved, and diazotization is carried out after filtration, and then condensation, coupling, salting out , filtering and drying to prepare monomer No. 1 reactive orange dye and B-BF reactive navy blue dye respectively. Mix 100 grams of No. 1 reactive orange dye, 400 grams of B-BF reactive navy blue dye, and 1-1.5 grams of butyl oleate and grind them to the required particle size.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com