Method for producing alkyl lithium

A production method and technology of alkyl lithium, applied in the direction of lithium organic compounds, etc., can solve the problems of long reaction period, uneconomical process, low production capacity, etc., and achieve the effects of stable reaction, improved production capacity, and reduced consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

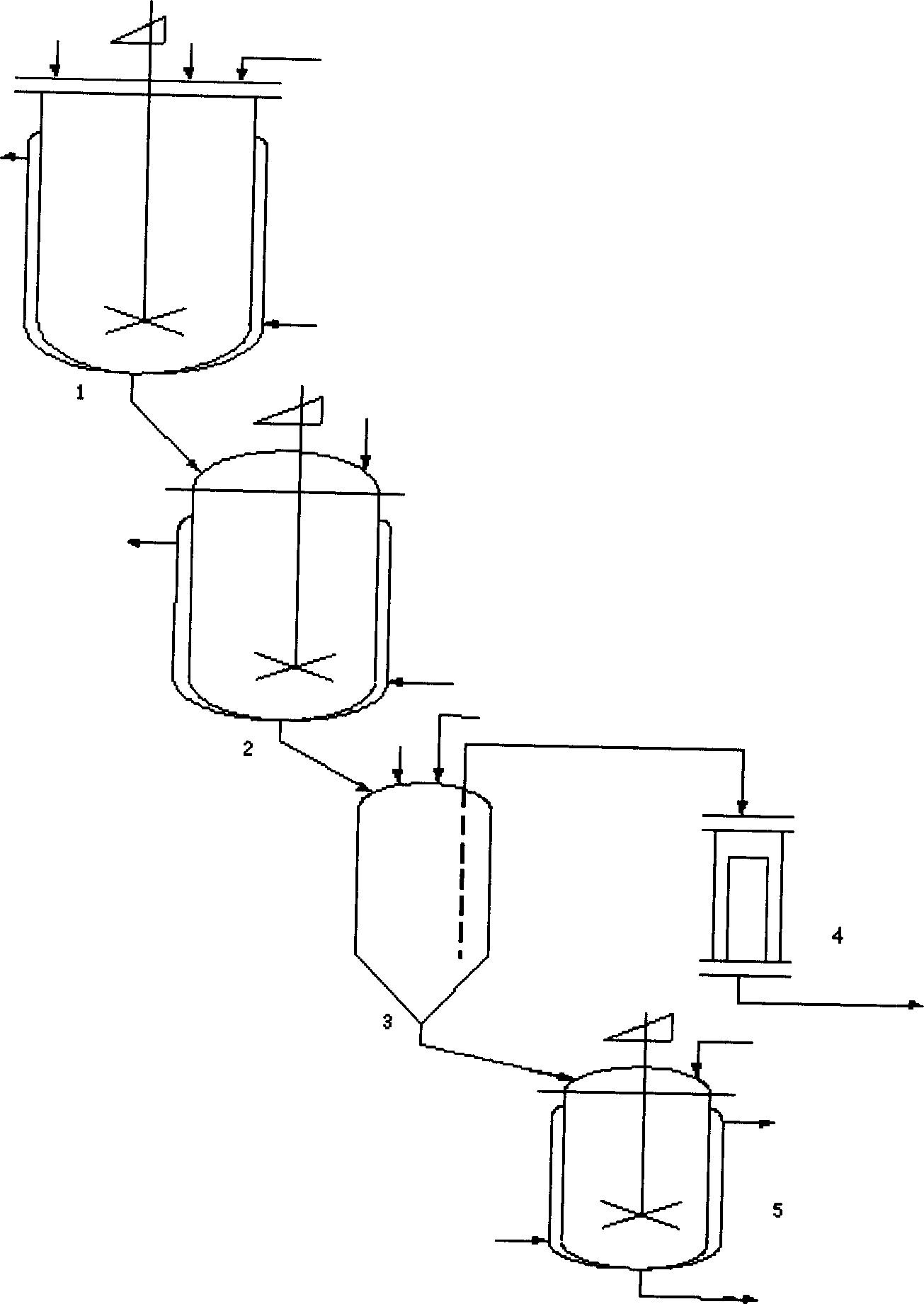

Method used

Image

Examples

comparative example 1

[0029] Comparative Example 1: Put 14.33kg of prepared lithium sand, 70L of dispersion medium white oil, and 600L of cyclohexane for washing the dispersion tank into the synthesis tank (the specific steps are the same as in Example 1). Add 93.8L of n-butyl chloride dropwise in the kettle (about 14% excess lithium than the theoretical value), control the reaction temperature to be 35-55°C, react and filter the rest according to Example 1 to obtain 430L of butyl chloride with a concentration of 1.10M light yellow and transparent Lithium solution with active C-Li content of 98.3%, residual BuCl content of 1.09%, Cl - The content is 275ppm. Add 800L cyclohexane into the settling tank, and after settling for 4 hours, pump the supernatant and filter to obtain a 0.26M concentration of butyllithium solution. The combined yield of the two is 76.6% based on chlorobutane. The lithium slag in the settling tank is discharged into the hydrolysis tank and then deactivated by hydrolysis.

comparative example 2

[0030] Comparative Example 2: 14.07kg of prepared lithium sand and 70L dispersion medium white oil, 600L industrial cyclohexane (composition is the same as Example 2) for washing the dispersion tank are put into the synthesis tank (the specific steps are the same as Example 1). Add 88.2L of n-butyl chloride dropwise into the kettle (about 19% excess lithium than theoretical value), control the reaction temperature to 35-55°C, react and filter the rest according to Example 1 to obtain 430L of butyl chloride with a concentration of 1.08M light yellow and transparent Lithium solution with active C-Li content of 98.7%, residual BuCl content of 0.89%, Cl - The content is 313ppm. Add 800L hexanaphthene in the settling tank, after the clear liquid is drawn out, the two are combined and the yield is 79.8% in terms of chlorobutane. The lithium slag in the settling tank is discharged into the hydrolysis tank and then deactivated by hydrolysis.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com