Automatic regulating and controlling method of wet steam boiler dryness

A technology of regulating control and wet steam, which is applied in the direction of steam generation, control system, lighting and heating equipment, etc., to achieve the effect of overcoming reliability and stable and reliable control results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

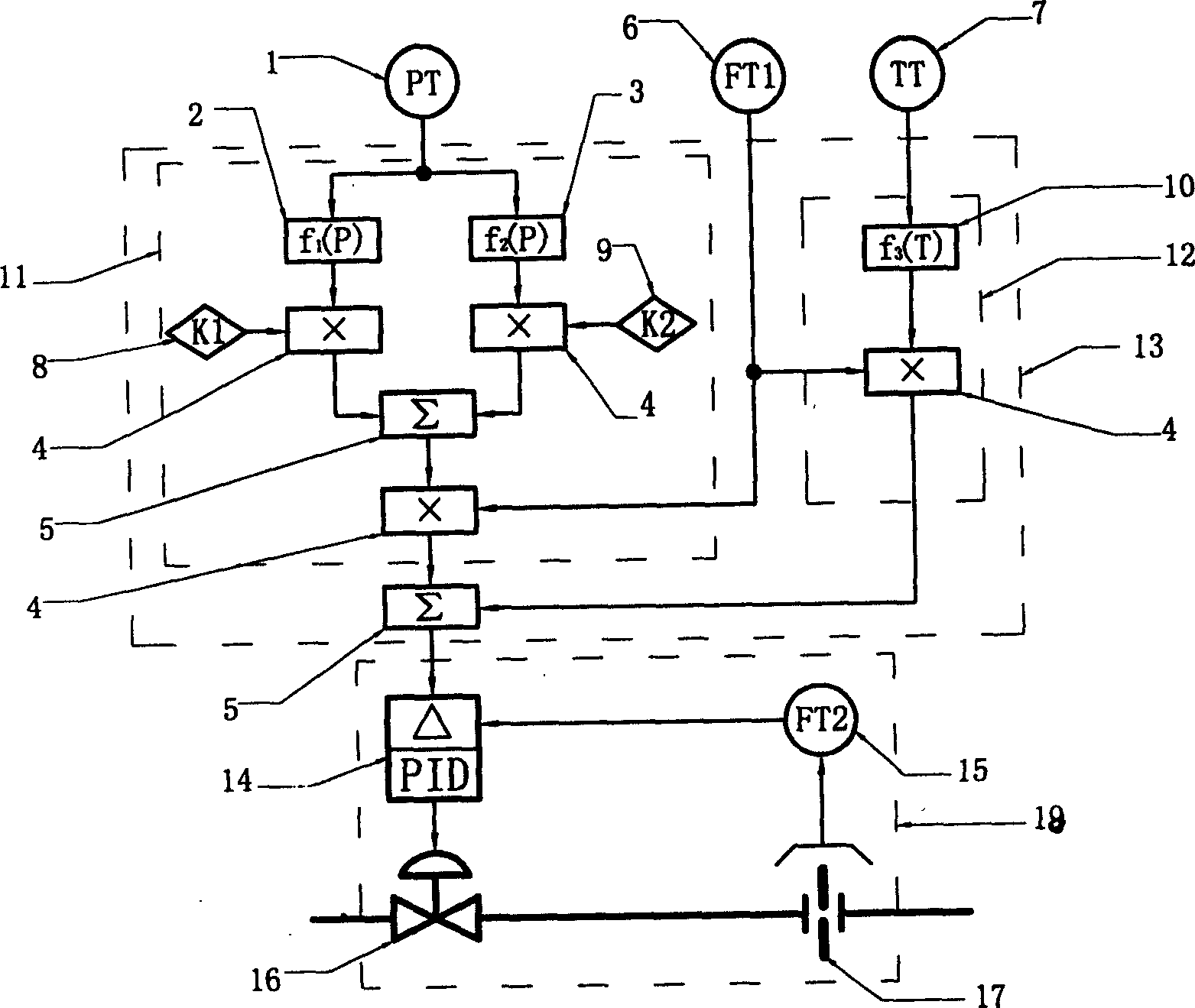

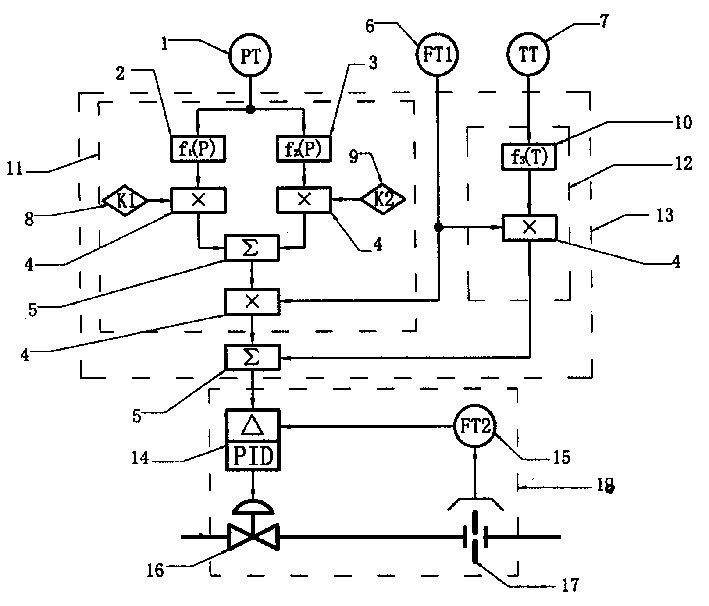

[0039] Step 1 Obtain the function f of the enthalpy per unit mass of saturated water and the enthalpy per unit mass of saturated steam with respect to pressure by looking up the table or other methods 1 (P) and f 2 (P), and the enthalpy per unit mass of water as a function of temperature f 3 (T). Then, according to needs, convert them into self-defined standard functions that can be accepted by the control system corresponding to the original functions one by one.

[0040] Step 2 According to the method provided in this paper or formula (1) andfigure 1 Draw the flow chart of the control system, or directly adopt figure 1 The flow chart of the wet steam dry degree adjustment control system is shown.

[0041] The third step is to connect the hardware device according to the flow chart, or compile the software input hardware device according to the flow chart.

[0042] The fourth step is to put into operation and debug the system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com