Collagen material and its producing method

A collagen material, collagen technology, applied in the direction of non-woven fabrics, textiles and papermaking, packaging food, etc., can solve problems such as difficult to manipulate materials, opacity of polyethylene glycol acid, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

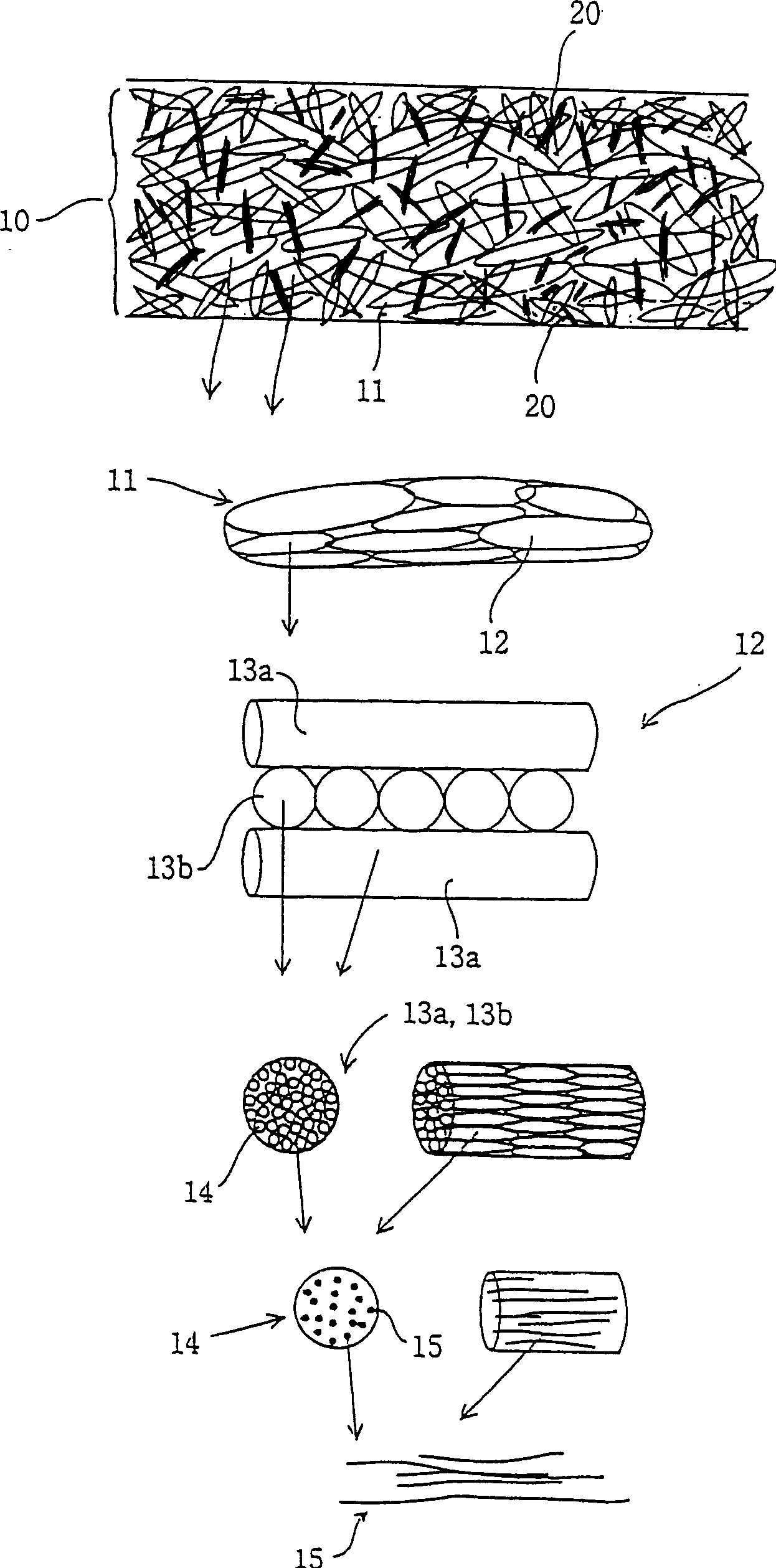

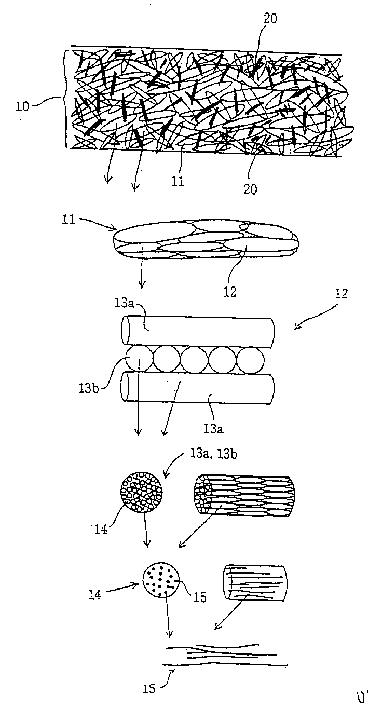

Image

Examples

Embodiment 1

[0085] A 1N hydrochloric acid solution (collagen concentration 1 wt %) for extracting collagen was formulated with collagen obtained from pig skin, and poured into a petri dish to form an 18 mm thick collagen solution layer. This was frozen at -20°C for 24 hours, followed by lyophilization at -80°C for 48 hours. Then carry out thermal dehydration and cross-linking at 140 DEG C for 24 hours under vacuum with the multidimensional structure body (hereinafter referred to as the multidimensional structure body) of this freeze-dried collagen fiber, and then use a glass water pump to make the inside of the multidimensional structure body form a negative pressure ( 50cm water column), and then introduce the 1N hydrochloric acid solution (collagen concentration 0.5wt%) of extracting collagen into this multidimensional structure, so that the gaps inside the multidimensional structure are embedded in non-fibrillated collagen, and then under the same conditions as described , freeze and f...

Embodiment 2

[0093] The collagen material of the present invention was obtained in the same manner as in Example 1 except that the collagen solution layer was formed five times on the compressed material. With regard to the collagen material, the point support tension and tensile strength in dry and wet states were measured by the same method as in Example 1. The results are listed in Table 1.

Embodiment 3

[0095] Except between the second freeze-drying operation and the compression operation, the operation of reducing the voids inside the multidimensional structure through thermal dehydration cross-linking treatment and newly forming fibrous collagen under the same conditions as described above and the Except that the compressed material was not subjected to the operation of forming a collagen solution layer, the point support tension and tensile strength in dry and wet states were measured according to the same method. The results are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com