Constructing method for treating soft foundation of highway by cement, flyash and macadam

A cement fly ash and soft foundation treatment technology, which is applied in the fields of infrastructure engineering, soil protection, construction, etc., can solve the problems of insufficient pile quality, bearing capacity and treatment depth, and restrict the quality of soft foundation treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

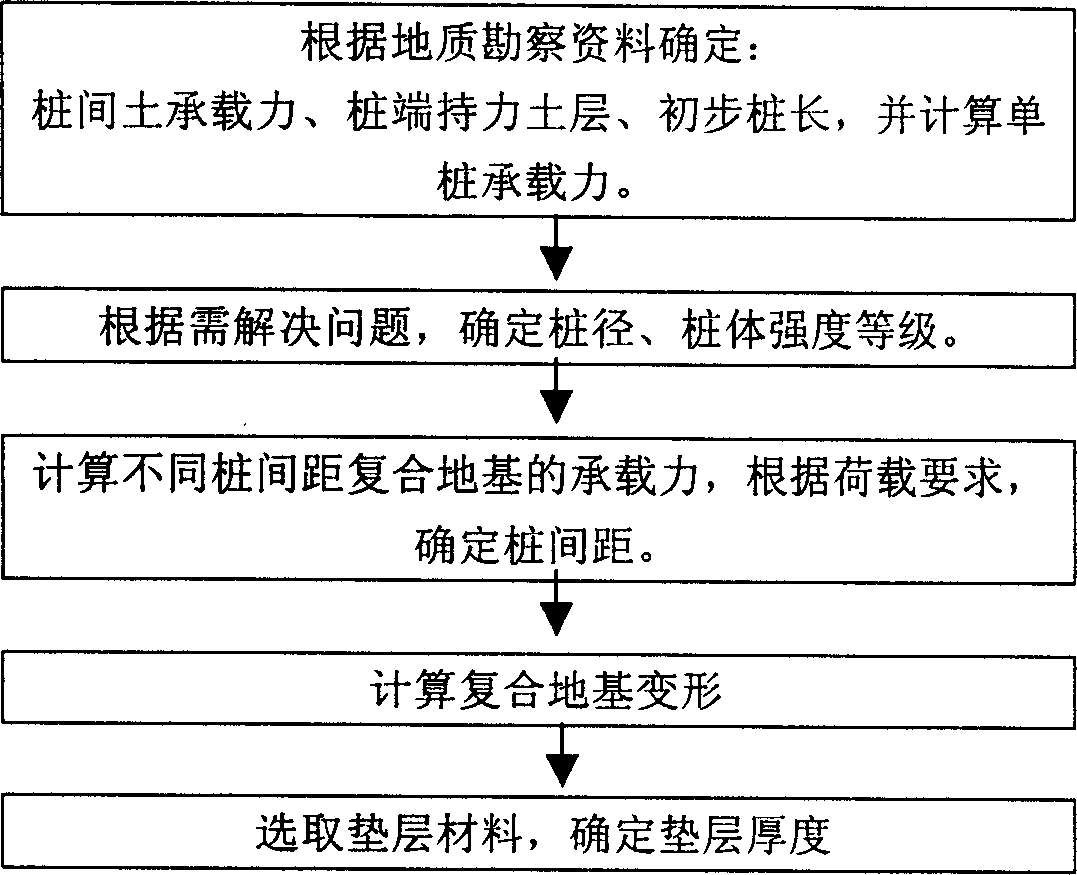

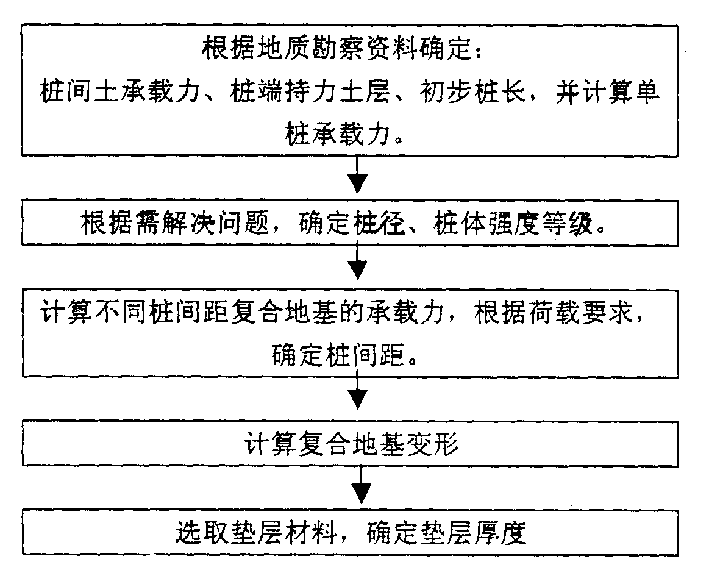

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1: Treatment of the subgrade of the bridge head section.

[0044] In order to reduce the post-construction settlement of the bridge head section and avoid the problem of bridge head jumping, the applicant carried out CFG pile treatment. According to the actual construction situation (bag sand well and sand cushion construction completed) and geological conditions, the CFG pile is designed to have a diameter of 50cm and a pile spacing of 1.8m, and it is required to drive 1.0m below the bearing layer (controlled by the hammer closing standard). The original drainage system can avoid the dissipation of super static pore water pressure caused by piling. The pile spacing and hammer collection standard are determined by the upper load of the foundation (embankment, vehicles, etc.) and the allowable post-construction settlement. During the laying process and after the completion of the construction, the settlement of the pier was observed. The cumulative settlement ...

Embodiment 2

[0045] Example 2: Treatment of subgrade in collapsed section.

[0046] Due to complex geology and rapid changes in the silt layer, K18+380~K18+545 near the Niuwan Interchange of Xintai Expressway in Guangdong Province slumped. At that time, the entire line embankment had been filled to the design height. If conventional methods or vacuum preloading were used, the construction period would be extended, and the uneven settlement of the old and new embankments would also cause cracks. In order to solve the above problems, the expert meeting decided to use CFG piles plus sand piles. In order to reduce the cost, the Design Institute adopts a variable spacing arrangement, with the pile spacing in the middle of the road being 1.5m, the pile spacing on the left and right road shoulders being 2.0m, and the pile spacing on the road slope being 2.5m. In order to dissipate the excess static pore water pressure and improve the consolidation degree of silt between piles, sand piles are add...

Embodiment 3

[0048] Embodiment 3: Treatment of widened roadbed.

[0049] The widening section of the toll station of the main line of the Niuwan Interchange of Xintai Expressway in Guangdong Province is treated with CFG piles. Since the filling of the main line is completed earlier, in order to prevent uneven settlement between the widening section and the main line, the spacing between the CFG piles is 1.5m, and the gravel pad is used. Layer 30cm. Open to traffic for 3 months, there is no crack caused by uneven settlement between the CFG pile treatment and the original roadbed, that is, the widening section and the main line.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pile diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com