Adjustable electronic thermostatic valve

An electronic constant temperature and adjustable technology, applied in the direction of control/regulation system, temperature control without auxiliary power supply, valve lift, etc., can solve problems such as damage, engine drop, and wire damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

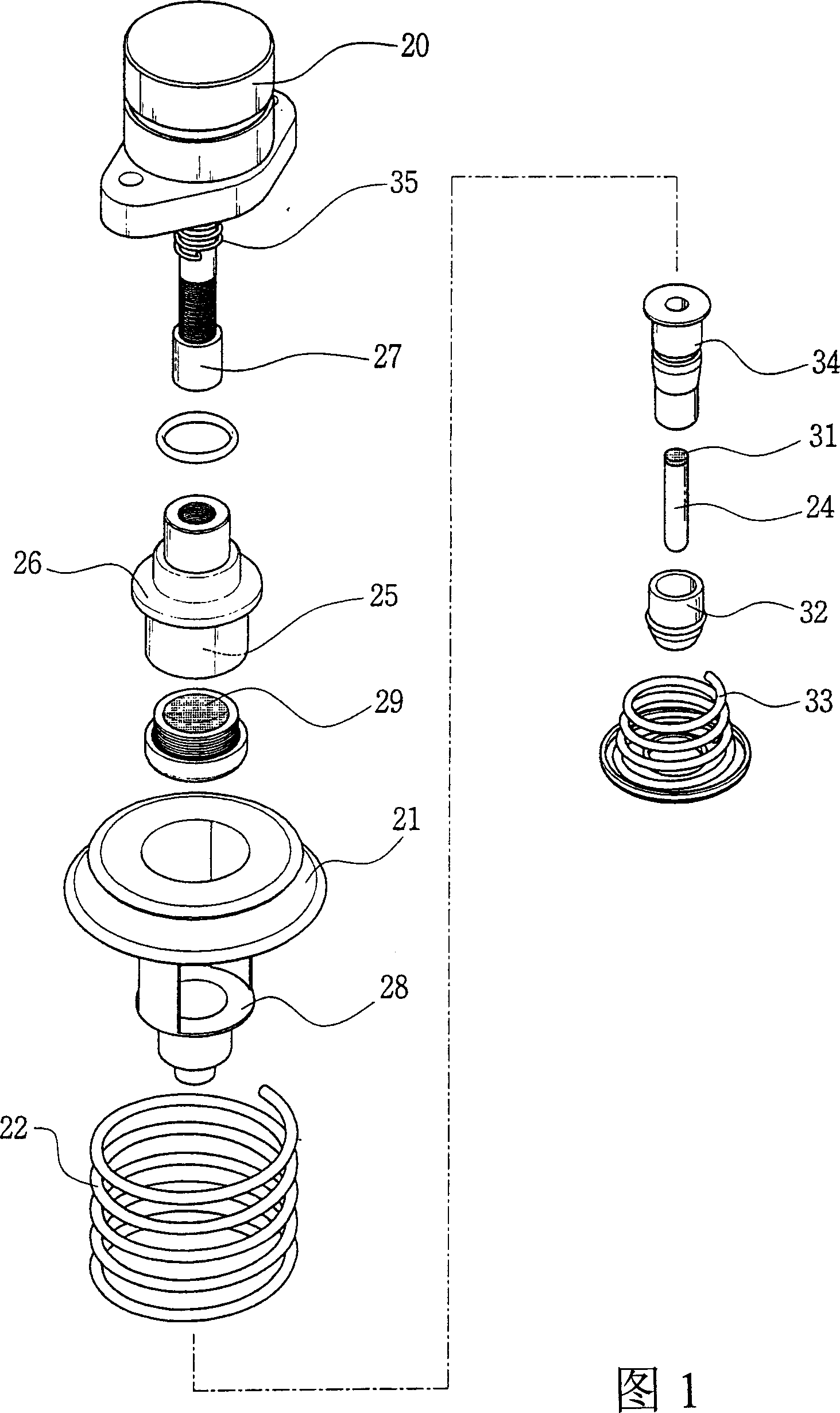

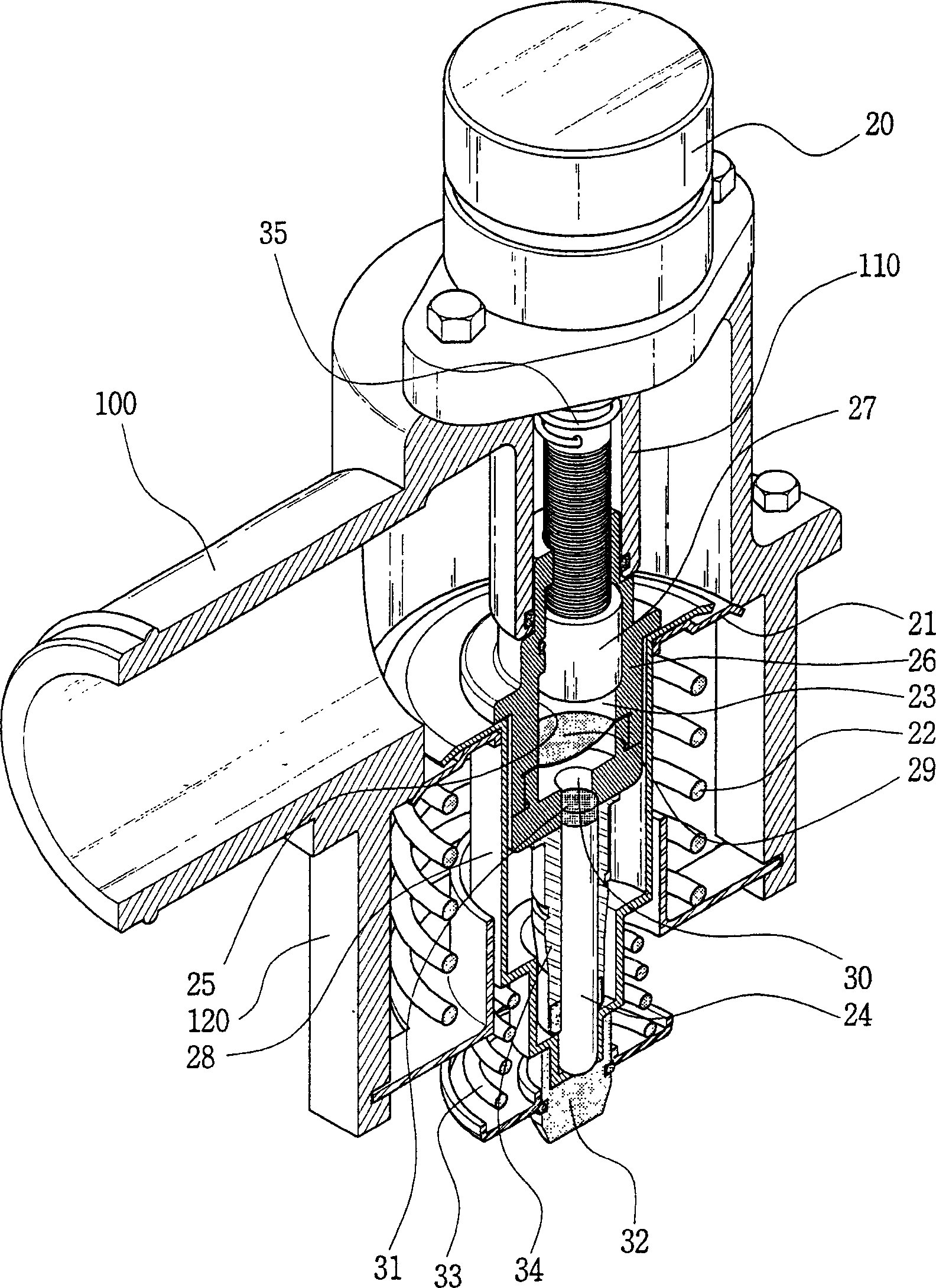

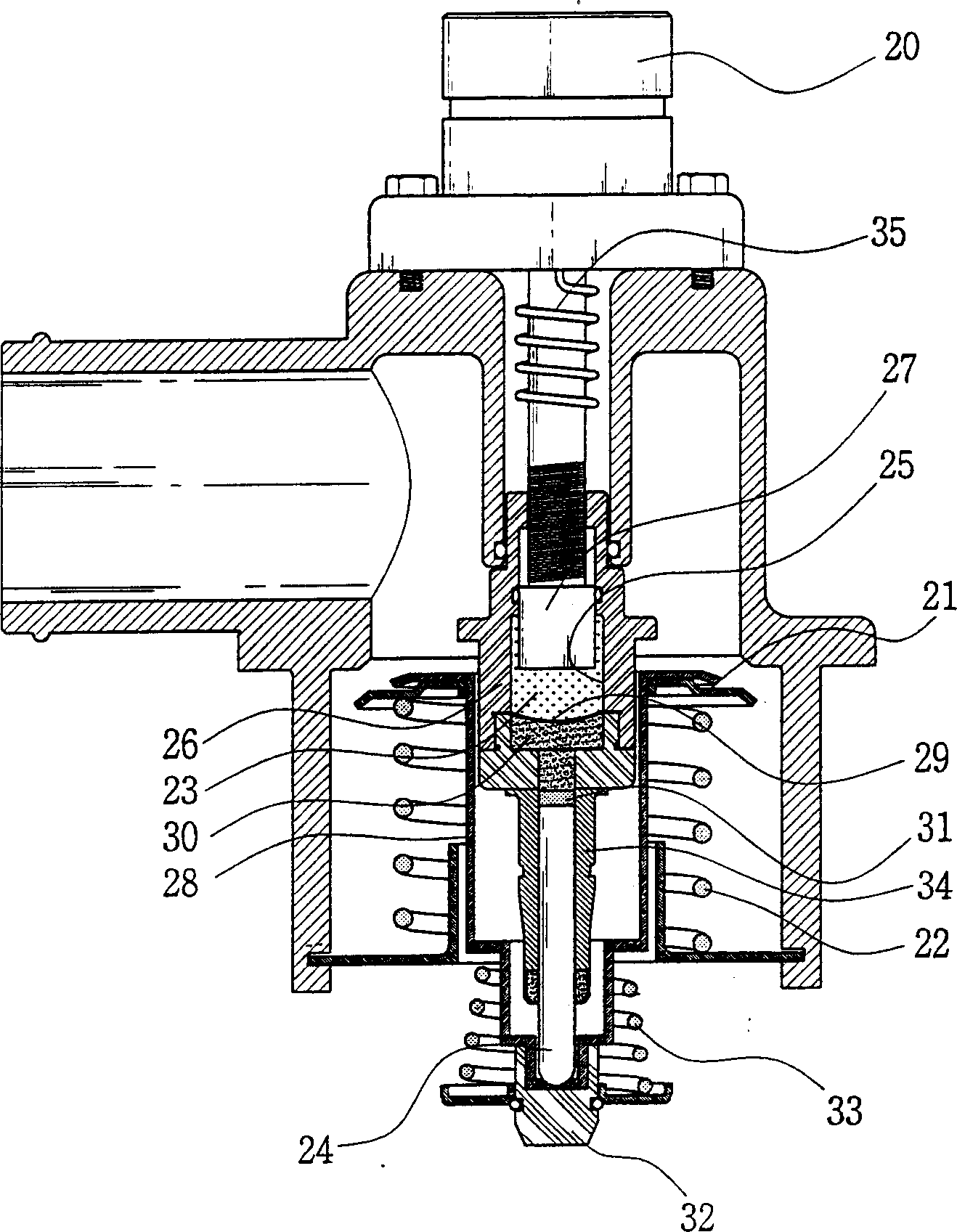

[0021] Next, a preferred embodiment of the present invention will be described in detail with reference to the accompanying drawings. Figure 1 and figure 2 As shown, the adjustable electronic thermostatic valve according to an embodiment of the present invention has a driving device 20 controlled by an electronic control unit (ECU) (not shown) on the vehicle and a container 26 with a chamber 25 for containing Chamber 25 is used to accommodate expandable thermal element 23 . The rod 27 of the drive means 20 is partially inserted into the chamber 25 and engages with the upper part of the container 26 by threads. Thus, the rotational movement generated by the drive device 20 is converted into a linear movement of the rod 27 via the thread on the rod 27 and the container 26 . The drive means used to generate motion in response to an input of electrical energy can be selected by one skilled in the art. Suitable devices include, for example, linear stepper motors, DC motors or li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com