Fastener driver with auxiliary fuel box measuring valve rod sealing adaptor

A technology of fastener driving and adapter, applied in the direction of manufacturing tools, nailing tools, etc., can solve problems such as structural fatigue, fuel leakage, damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

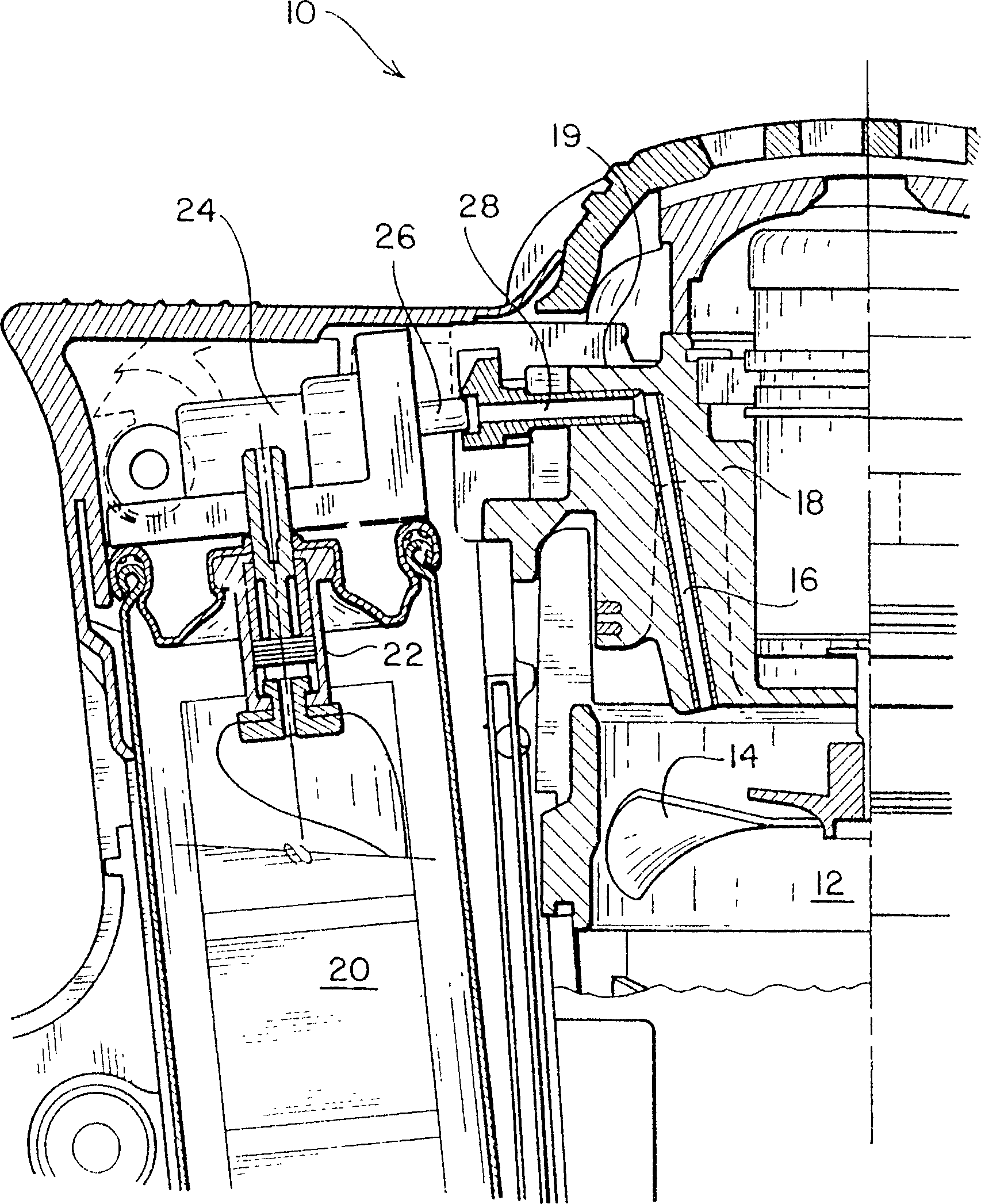

[0022] See now the attached drawings, especially the Figure 4 , disclosed is a fuel tank powered fastener driving tool in which a new and improved auxiliary fuel tank gauge valve stem seal adapter constructed in accordance with the principles and teachings of the present invention may be utilized, which The tool is indicated generally at 110 . Figure 4 shown in Tool 110 with figure 1 The tool 10 shown in is similar, therefore, the tool 110 and the corresponding components in the tool 10 will be indicated by corresponding reference numerals, except that the labeling of each component in the tool 110 is within the range of 100 series.

[0023]Correspondingly, briefly, since such fastener driving tools are well known in the art industry, the fastener driving tool 110 seen in the figures includes a trunk portion 101 defining a burner The combustion chamber 112 and the air-fuel mixture distribution fan 114 are arranged in the combustion chamber 112 . The piston 102 is vertical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com