Forced oil and forced air cooling control device of power transformers

A technology for power transformers and control devices, which is applied to emergency protection circuit devices, temperature control using electric methods, DC motor speed/torque control, etc. Acceleration shock, fan and oil pump motor failure and other problems, to improve the overall reliability, avoid full stop of air cooling, and protect the motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

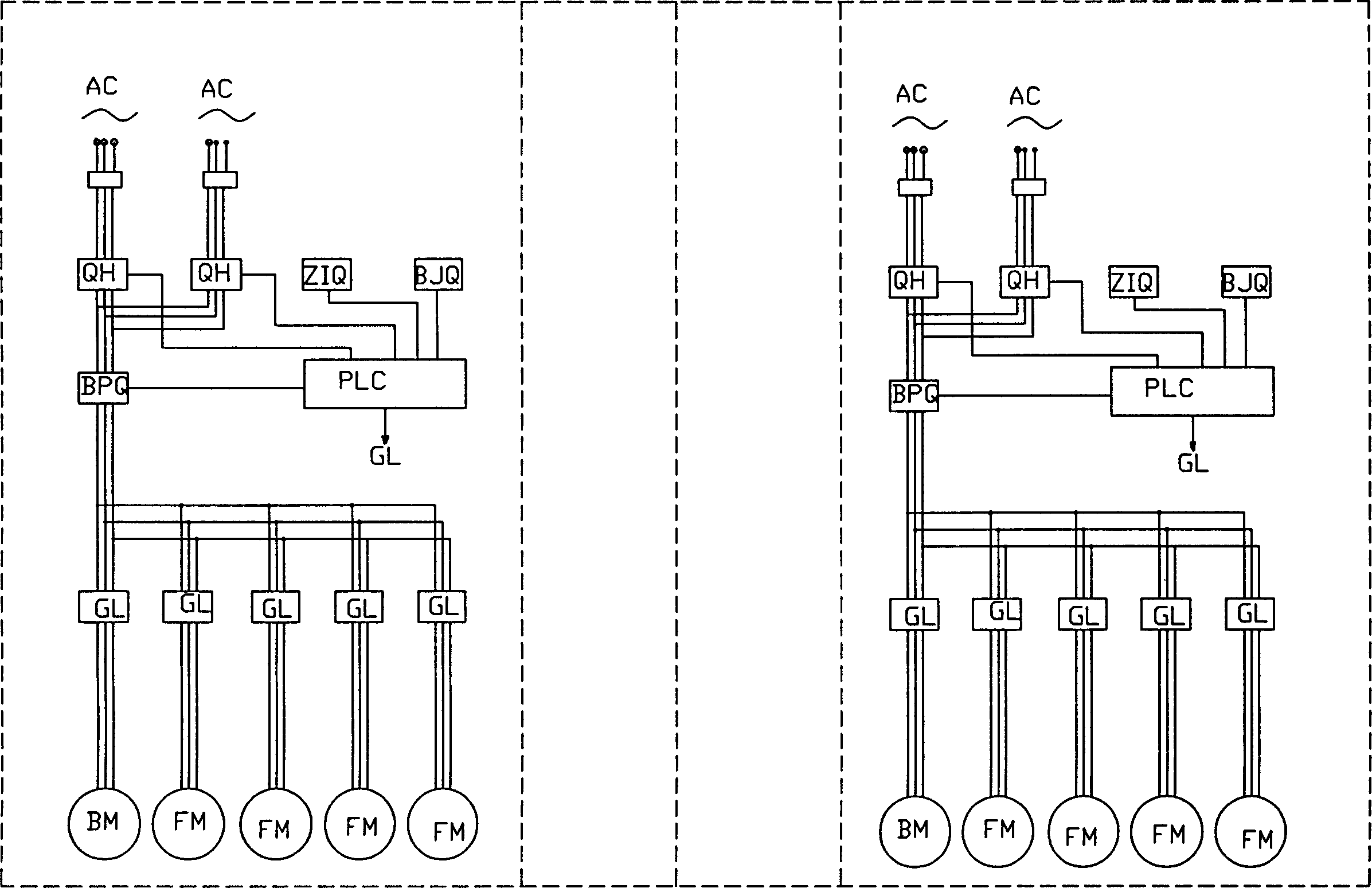

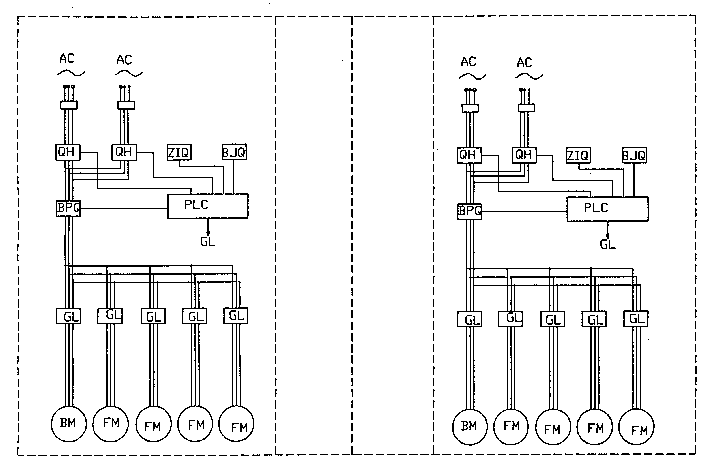

[0009] As shown in the figure, the present invention includes multiple groups of coolers made up of fan FM and oil pump BM, and the inlet end of each group of coolers is connected with a frequency conversion governor BPQ controlled by a single-chip PLC; in the fan FM, The inlet ends of the oil pump BM are respectively connected in series with overcurrent protectors GL, and the signal output terminals of the overcurrent protectors GL are connected to the signal input interfaces of the single-chip microcomputer PLC. A power switch QH controlled by the single-chip PLC is arranged at the incoming line end of the frequency conversion speed regulator BPQ; a working status indicator ZIQ and an alarm BJQ are connected to the output interface of the single-chip PLC.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com