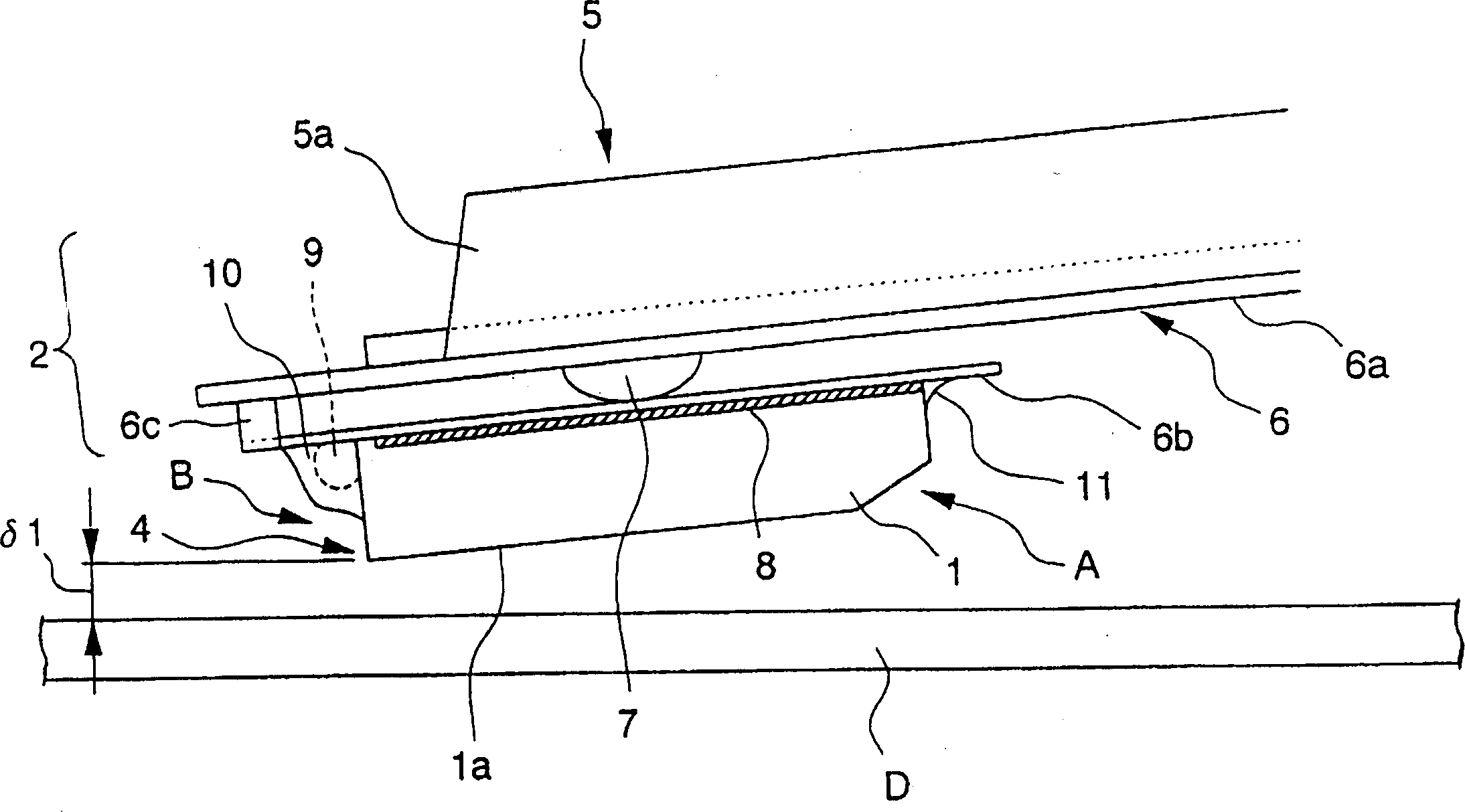

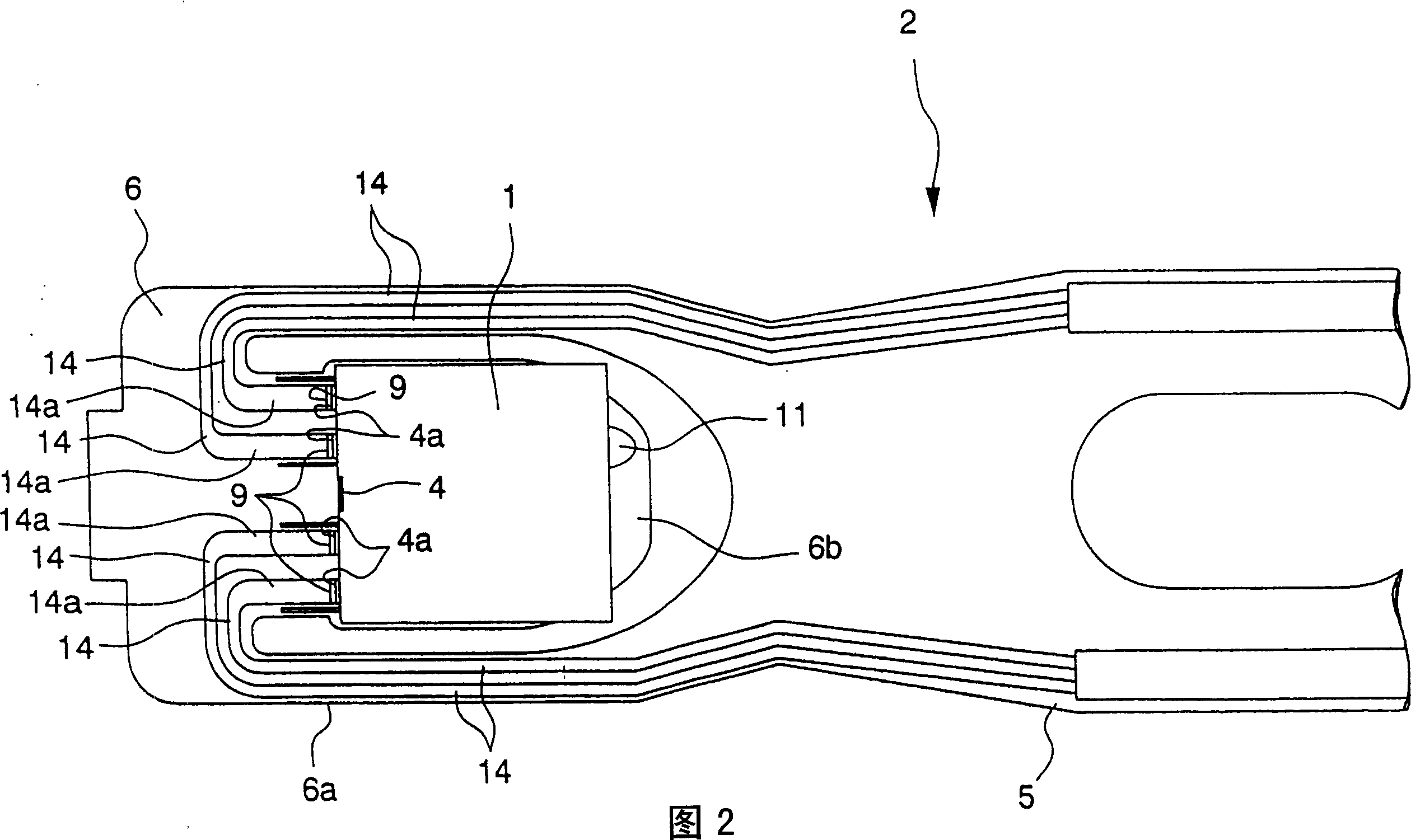

Magnetic head for conducting slider and bracket by conductivity resin

A conductive resin, magnetic head technology, applied in the direction of support head, magnetic recording, circuit device, etc., can solve problems such as inability to ensure the conduction between the slider 1 and the cantilever 6, electrostatic damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0106] First, as Example 1, a silver-based conductive filler with a particle diameter of about 1 to 5 μm and an outer diameter of 5 nm were prepared as a conductive resin film for the magnetic head having the structure of the aforementioned embodiment. About the material of carbon nanotubes. Carbon nanotubes, for the conductive adhesive weight 100% (the thermosetting resin of epoxy type 16% by weight, the conductive filler of silver type 84% by weight) ) added 10% by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com