Method and device for controlling febric output for loom

A loom and fabric technology, applied in the field of controlling fabric output, can solve the problems of unclear fabric structure boundaries, etc., and achieve the effect of suppressing changes in warp tension and suppressing changes in warp tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

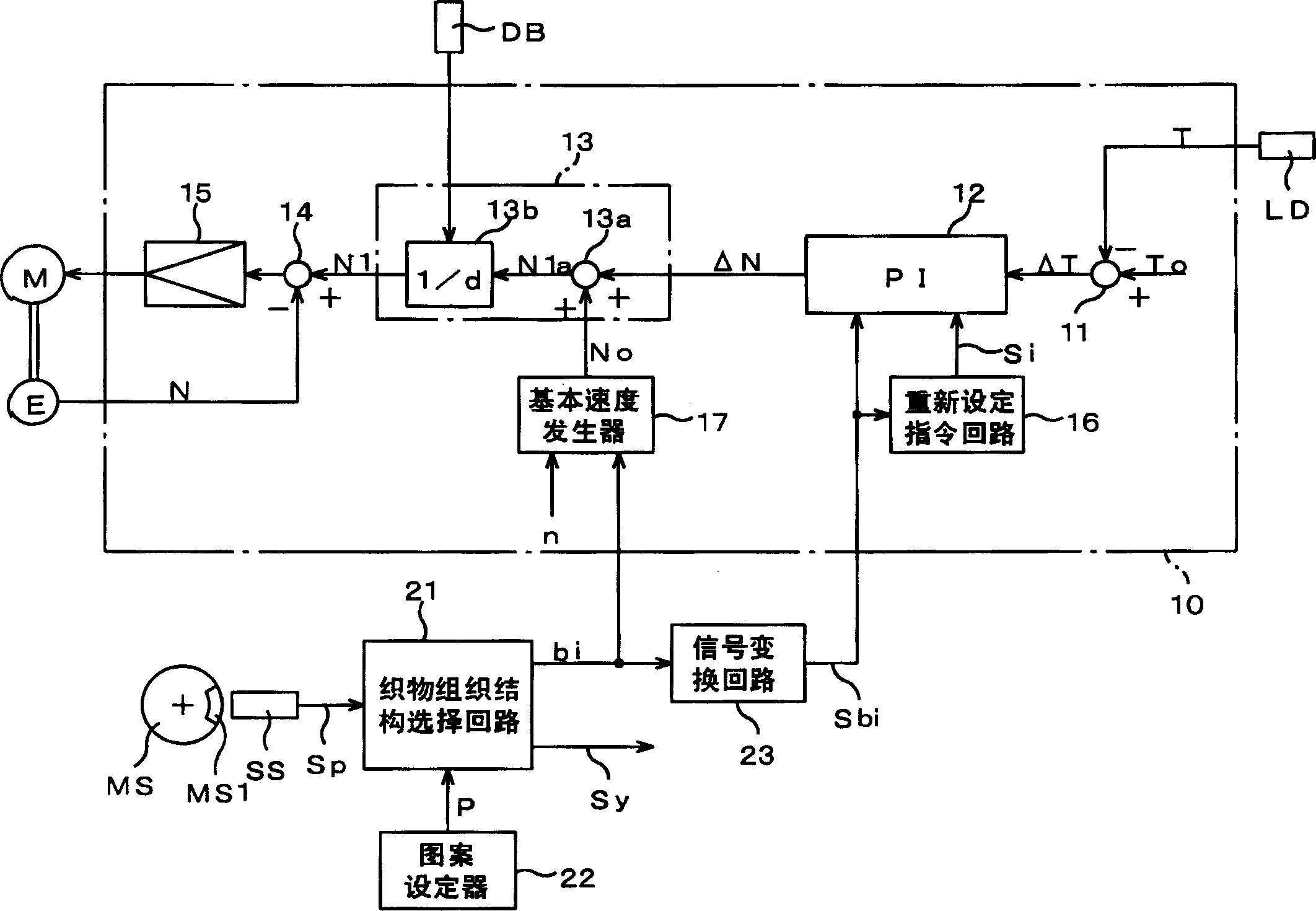

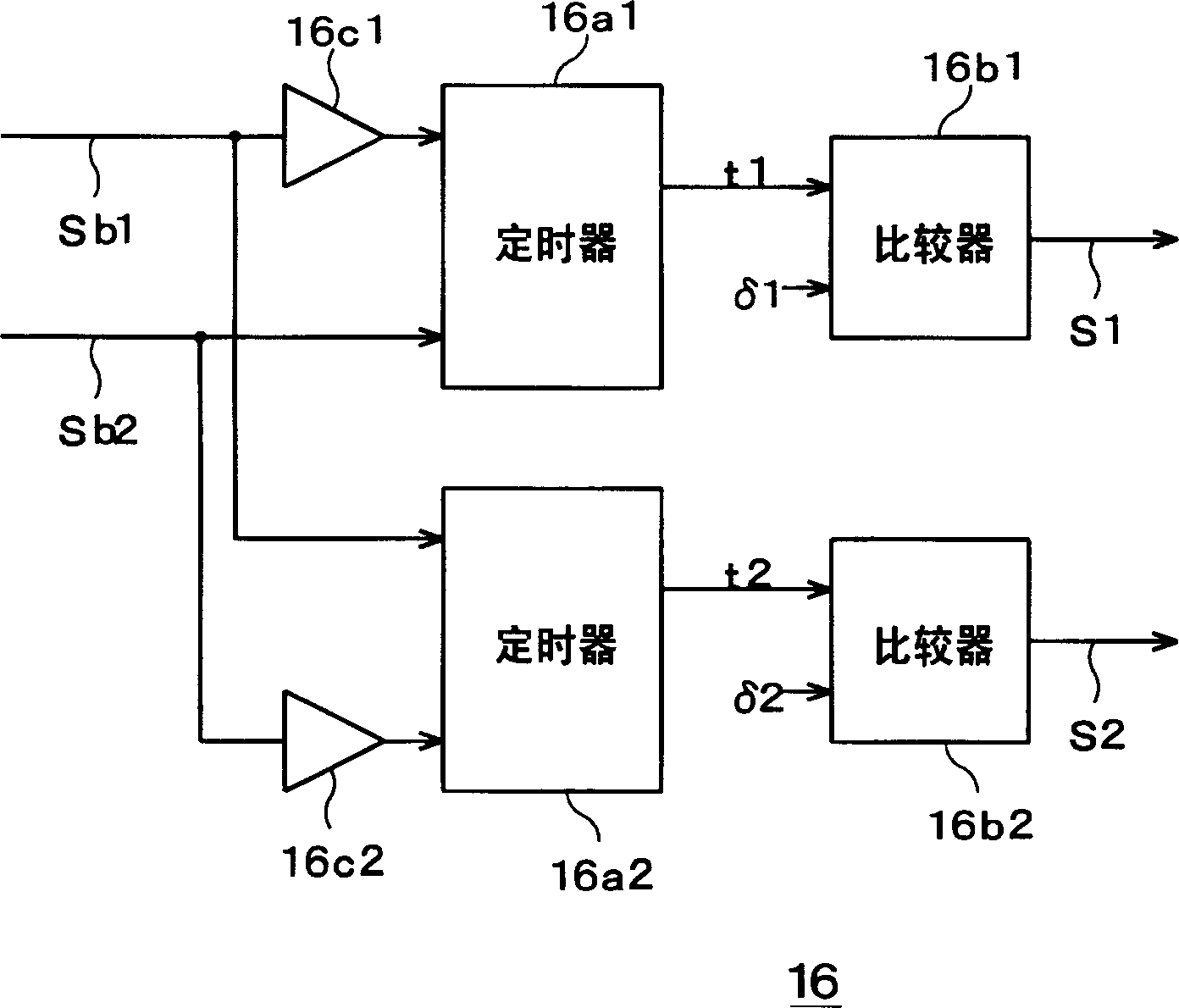

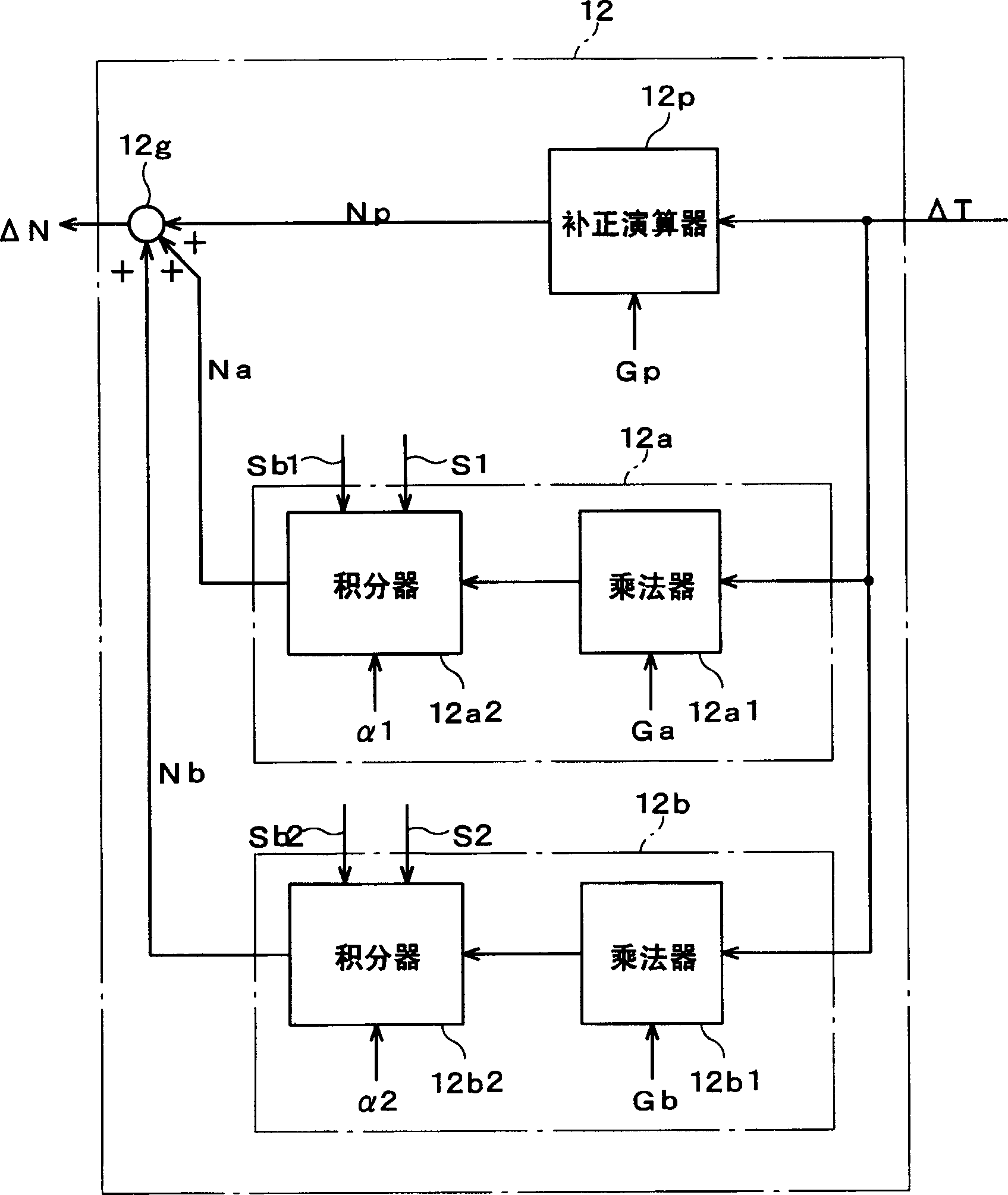

[0033] The output control device 10 of the loom includes a correction calculation device 12, a command speed calculation device 13, and a basic speed generator 17 ( figure 1 ). At the same time, the correction calculation device 12, the command speed calculation device 13, combined with the synthesis points 11, 14, and the control amplifier 15 form a speed control system for the output motor M. exist figure 1 Among them, the output motor M, the tension sensor LD, the roll diameter sensor DB, and the rotation sensor E correspond to Figure 10 Machines with the same symbol in . In addition, a resetting command circuit 16 is attached to the correction calculation device 12 .

[0034] The set tension To set by a setting device not shown and the warp tension To from the tension sensor LD are respectively input to the addition end point and the subtraction end point of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com