Combined water draining device and its connecting method

A drainage body and support plate technology, applied in the field of drainage materials, can solve the problems of reduced drainage efficiency, easy blockage of joints, low drainage efficiency, etc., and achieve the effects of reduced water flow space, expanded water permeable range, and reduced drainage efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

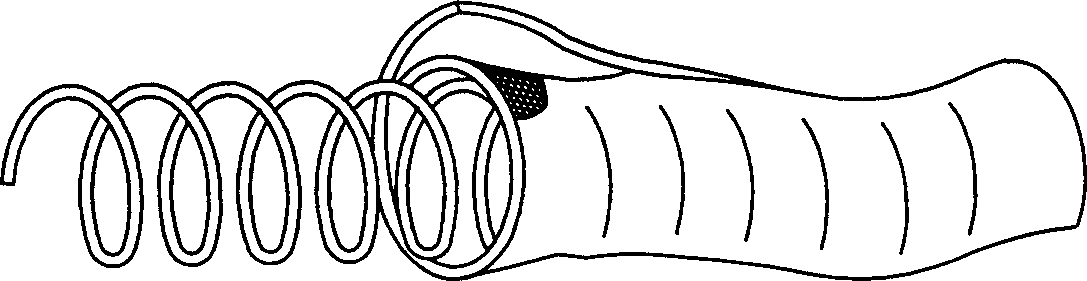

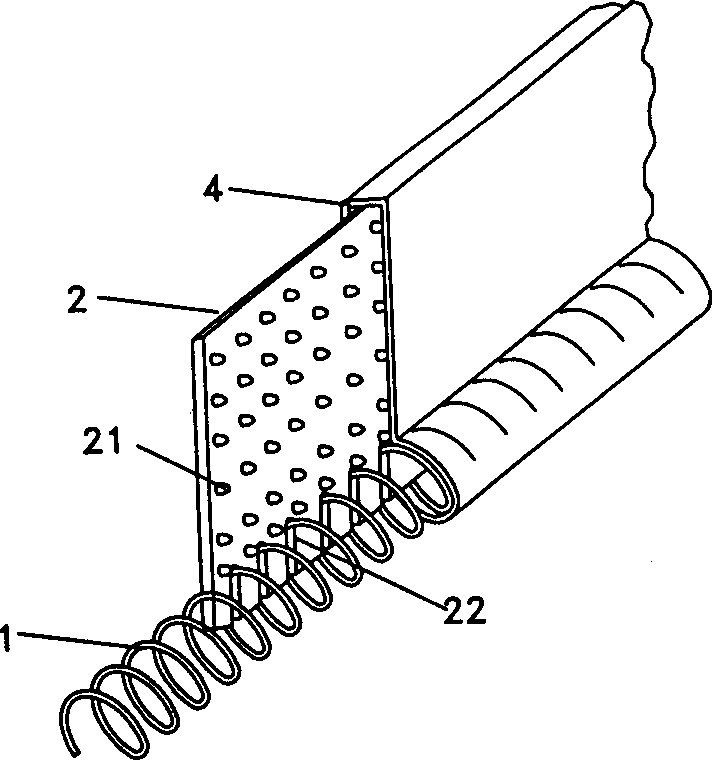

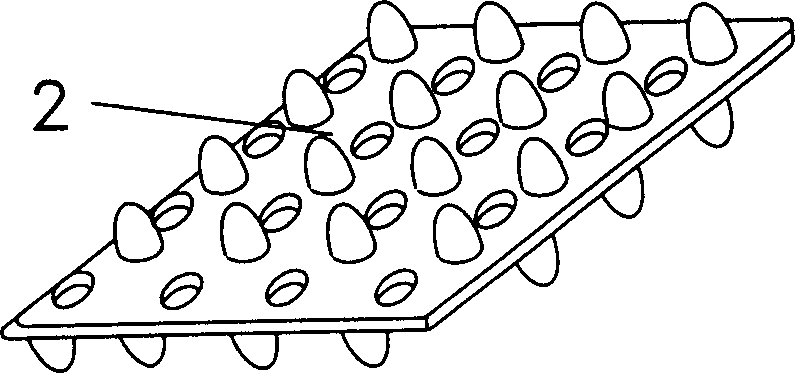

[0036] figure 2It is a structural schematic diagram of the first embodiment of the present invention, which includes a spiral spring tube 1 and a permeable support plate 2, wherein the spring tube 1 is bent from a helical high-strength rust-proof spring wire, and the permeable support plate 2 is a 21 plastic plates, the discrete protrusions 21 can support the overlying geotextile 4 to permeate and drain water, the spring tube 1 and the support plate 2 are embedded with each other, that is, a spring wire matching with the spring wire is arranged on the edge of the support plate 2 Group belt slit 22, the spring wire snaps into the corresponding belt slit to form an inlay body. In the above-mentioned inlay body, one side edge of the support plate 2 extends into the spring tube; the outside of the inlay body is wrapped with a geotechnical Cloth 4, the geotextile can be stitched by adding a piece of geotextile to cover the suture hole; it can also be sewn on the plastic support pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com