Multi-stage liquid curtain spray washing flue gas desulfurizing deivce

A desulfurization device and flue gas technology, applied in the direction of dispersed particle separation, chemical instruments and methods, separation methods, etc., can solve the problems of short mixing time of desulfurization liquid and flue gas, low desulfurization efficiency, etc., to facilitate installation and maintenance, Effects of improving utilization, enhancing turbulence and gas-liquid mass transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

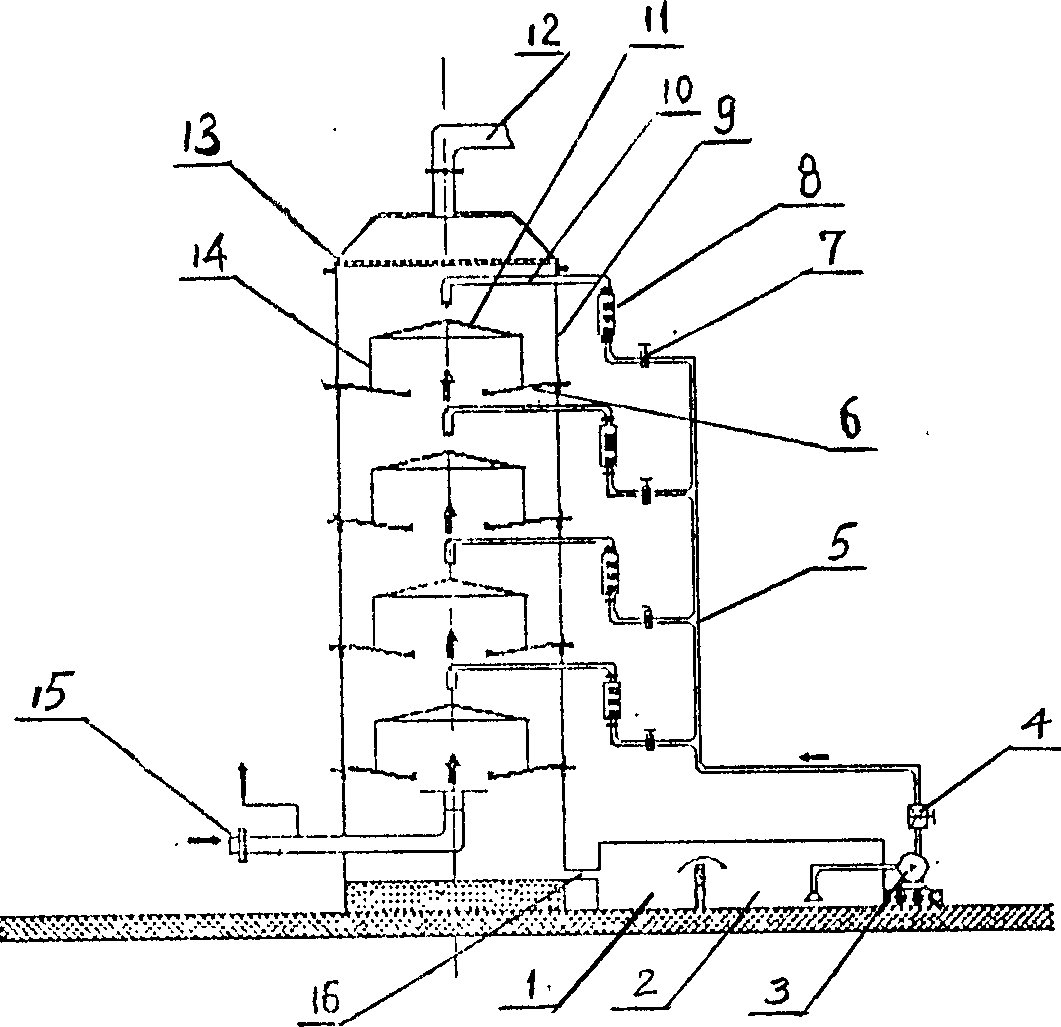

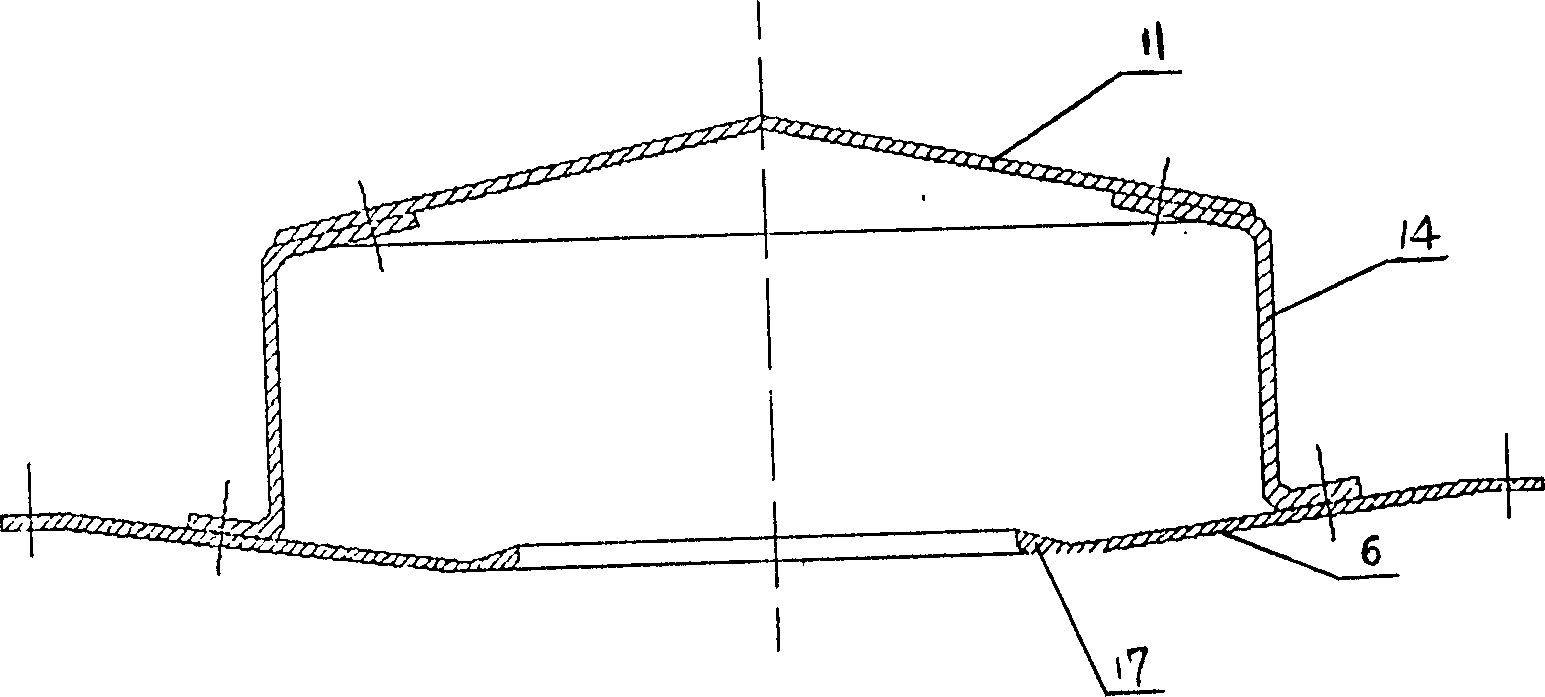

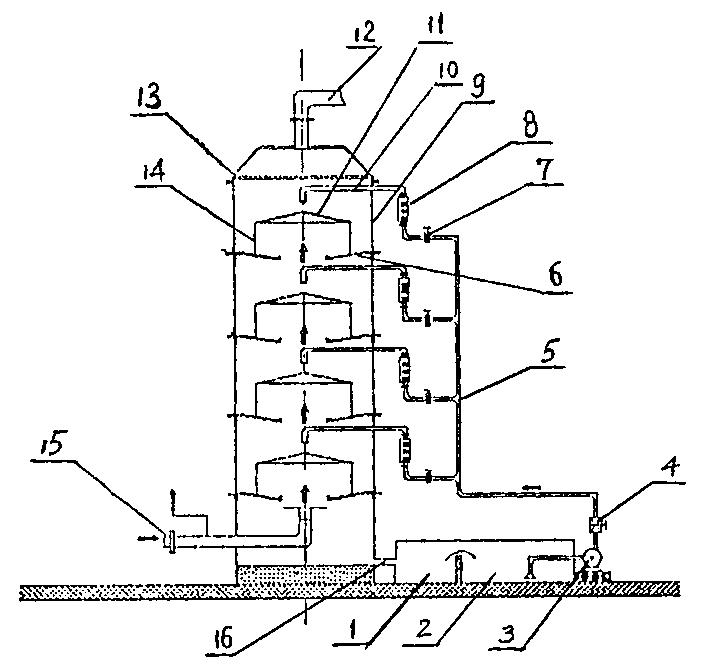

[0008] Depend on figure 1 As shown, the multi-stage liquid curtain spray washing type flue gas desulfurization device includes valve 4, circulation pump 3, desulfurization liquid pool 2, overflow pool 1, regulating valve 7, flow meter 8, desulfurization liquid inlet pipe 5, desulfurization liquid The return pipe 16, the barrel body 9, the desulfurization liquid spray pipe 10, the flue gas inlet 15, and the flue gas outlet 12 are characterized in that there are multi-stage desulfurization pipes corresponding to the multi-stage desulfurization liquid spray pipe 10 in the barrel body 9. The tower, the desulfurization tower adopts the lower stop ring 6 and the top cover 11 which can not only prevent the short circuit of the flue gas, but also enhance the gas-liquid mixing to form an inner stop structure. The lower stop ring 6 and the top cover 11 are connected by a bracket 14, and the bracket 14 Stainless steel flat steel is used. In order to facilitate installation and maintenanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com