Scraper for piston rod of reciprocating compressor

A technology of scraping device and piston rod, which is applied in the direction of engine sealing, liquid variable displacement machinery, mechanical equipment, etc., and can solve the problems of scraper ring wear, oil scraping function deterioration and oil leakage hazards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

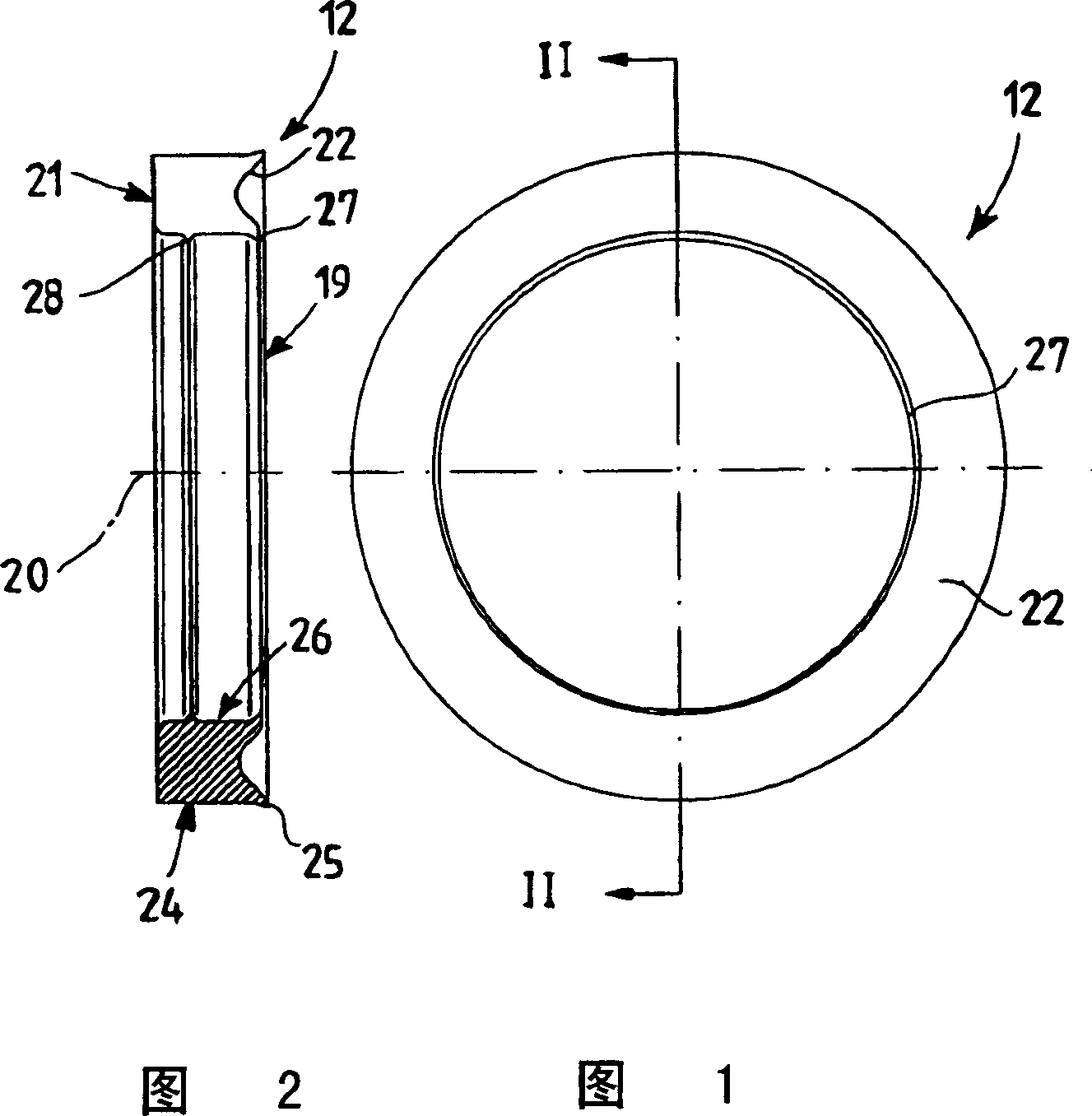

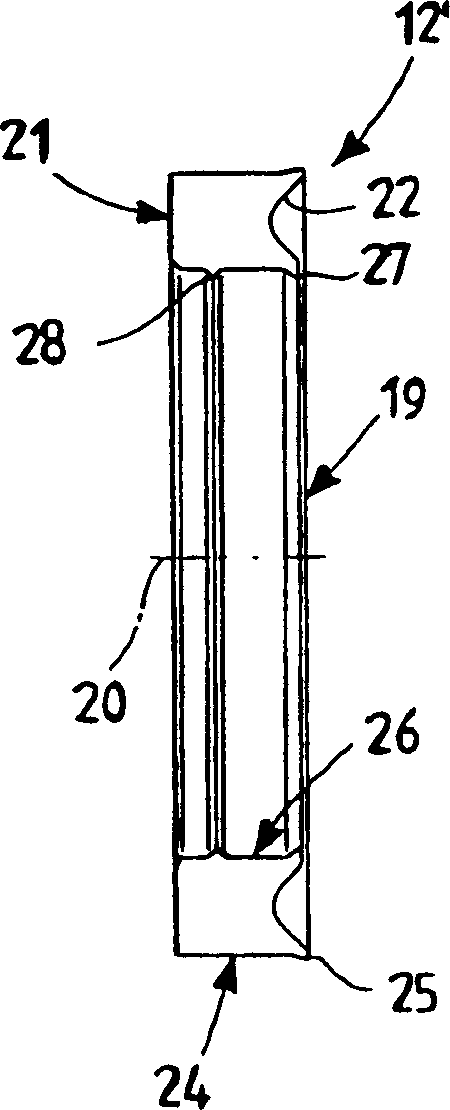

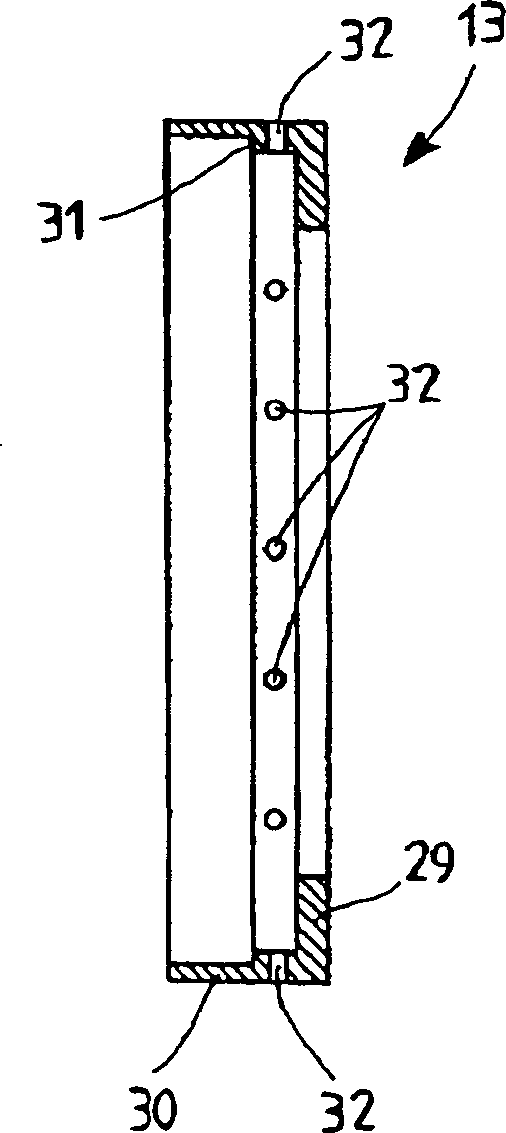

[0033] The scraping device shown in these figures is indicated generally at 10 and is mounted on the piston rod 11 of the reciprocating compressor. The scraper device 10 which is the subject of the invention comprises a scraper ring 12 and a box 13 which houses the scraper ring 12 and centers it on the piston rod 11 .

[0034] The scraper device 10 is shown in Figure 5 Fitted in a corresponding seat on the inner diameter of the support element 14 and in a transverse receiving element 16 clamped together by tie rods 15 . These supporting elements 14 and receiving elements 16 form the housing separating the crank mechanism and the compression chamber, neither of which is shown in this figure, which schematically shows a possible assembly.

[0035] The side facing the compression chamber is downstream of the scraping means, where there is no longer any lubricating oil, and a sealing means 17 is also provided. The sealing device 17 includes a corresponding sealing member, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com