Shortening full-length electron gun and cathod-ray tube device using it

An electron gun and cathode technology, which is applied in the direction of cathode ray tube/electron beam tube, electrode device and related components, discharge tube solid thermionic cathode, etc., can solve the problem of shortening the overall length of the cathode ray tube

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0041] [1-1] Structure of cathode ray tube device

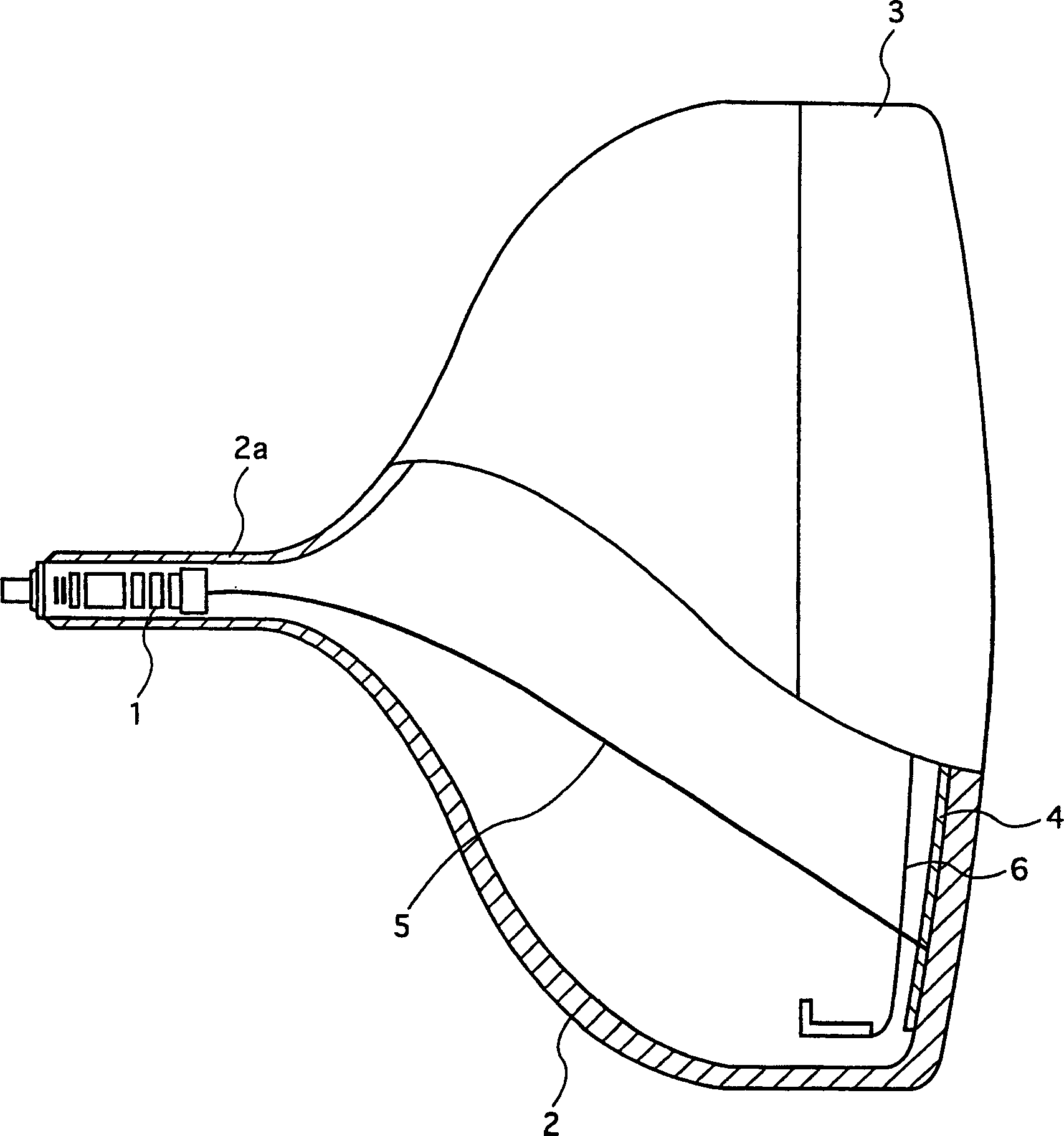

[0042] figure 2 It is a side view of the cathode ray tube device according to the first embodiment of the present invention, showing a partially cutaway cross section. like figure 2 As shown, the cathode ray tube device according to this embodiment has a peripheral frame composed of a funnel 2 and a screen 3 . The electron gun 1 is housed inside the neck 2 a of the funnel 2 . Further, blue, green, and red phosphors are coated on the inner surface of the screen 3 to form a phosphor screen 4 .

[0043] When the electron gun 1 receives an input signal, it emits electron beams 5 corresponding to the above-mentioned phosphors of each color. The electron beams 5 pass through openings formed in the shadow mask 6 to reach the fluorescent screen 4 . The phosphor screen 4 emits fluorescence when the electron beam 5 is incident to display an image.

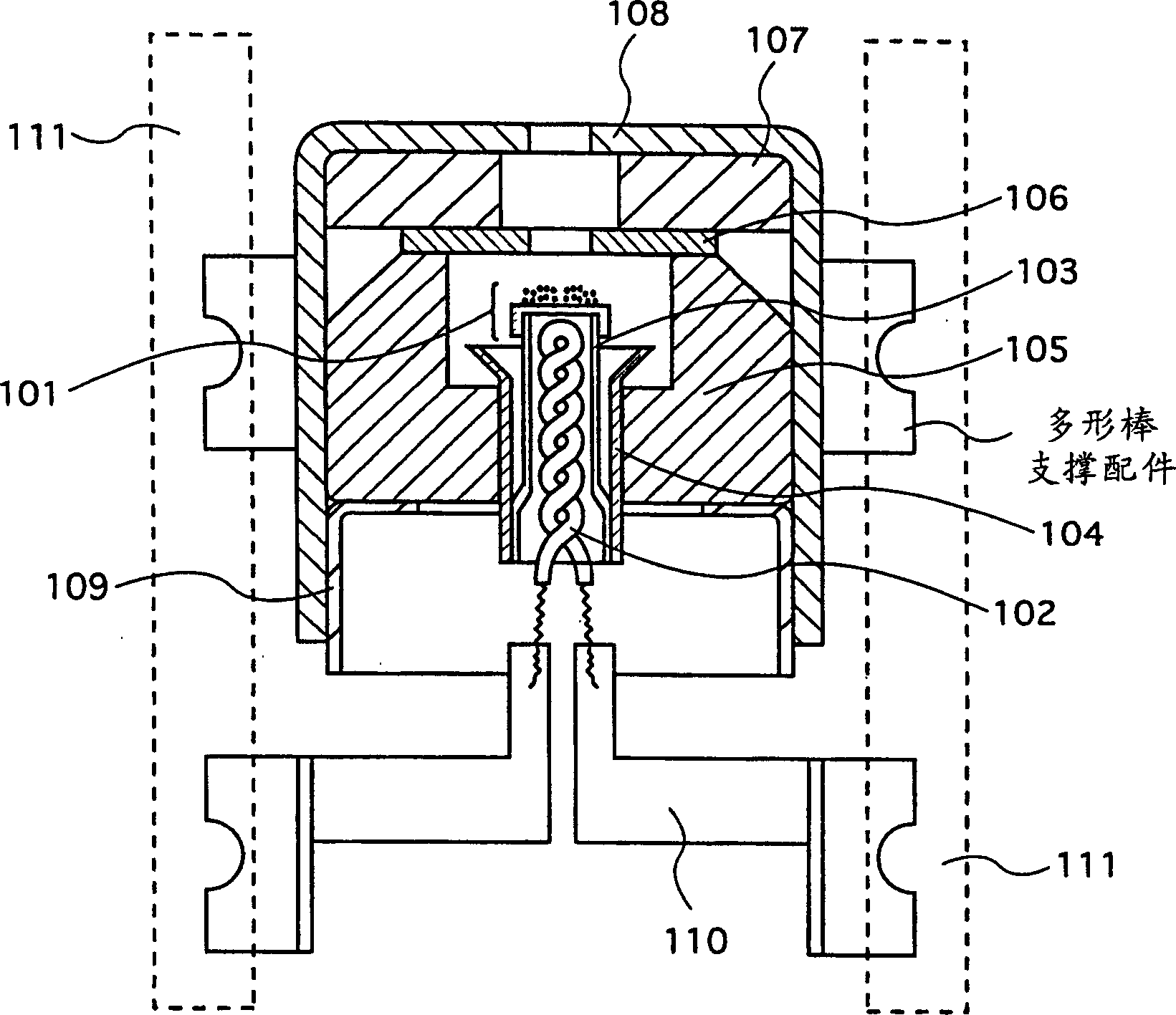

[0044] The electron gun 1 is provided with hot cathodes, accelerating electrode...

no. 3 example

[0096] A cathode ray tube device according to a third embodiment of the present invention will be described below with reference to the drawings. The cathode ray tube device according to this embodiment has substantially the same structure as the cathode ray tube device according to the above-mentioned first embodiment, and has a feature in the structure of a cathode unit integrally constituting a cathode and a control electrode. In the following, for ease of understanding, components having corresponding components in the first embodiment will be described using the same reference numerals.

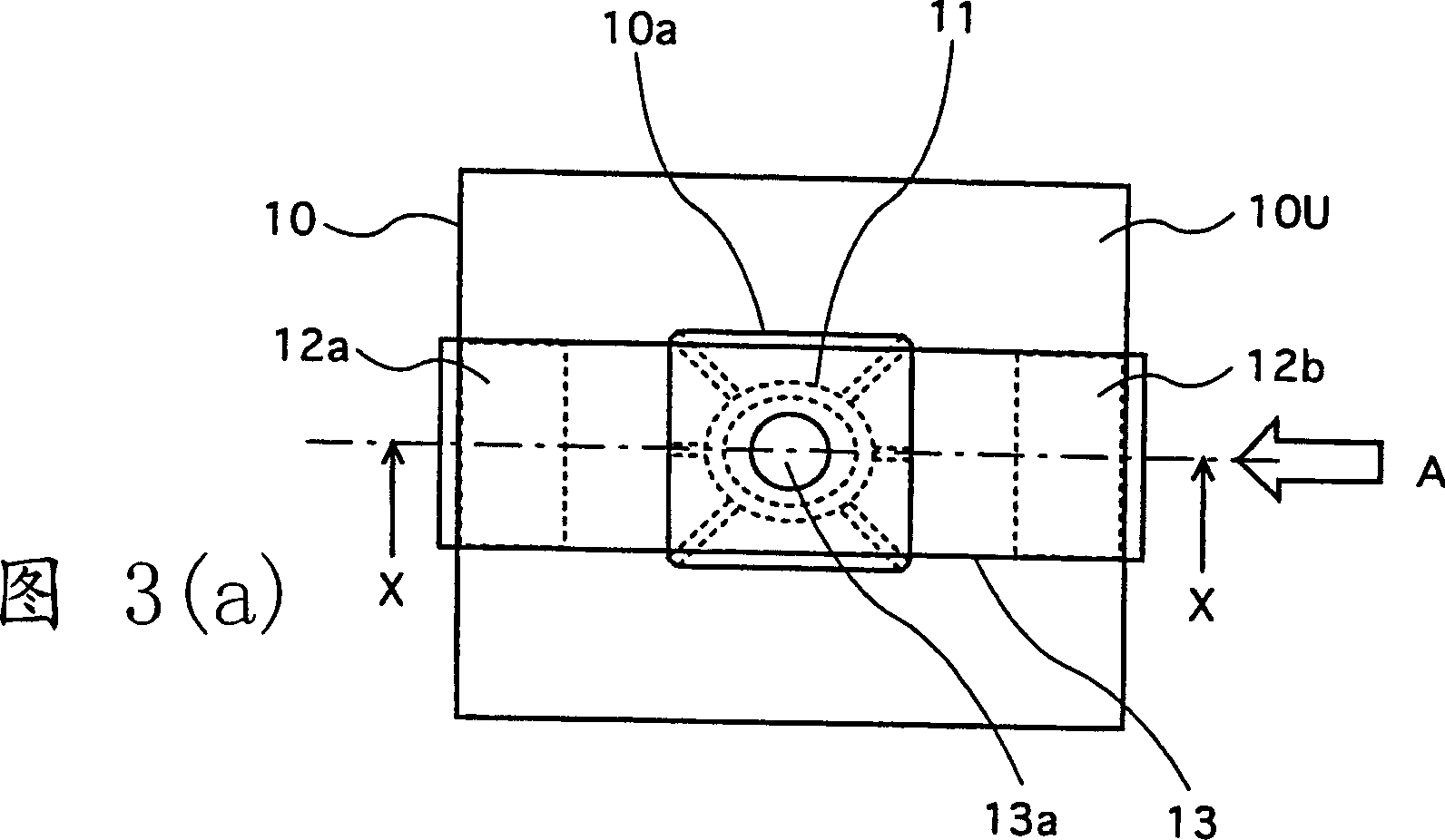

[0097] 6 is a diagram showing the structure of the electron gun of the cathode ray tube device according to the present embodiment, paying particular attention to the cathode unit. FIG. 6(a) is a view of the cathode unit viewed from the phosphor screen 4 side. FIG. 6( b ) is a view of the cathode unit viewed from the arrow A direction shown in FIG. 6( a ).

[0098] As shown in FIG. 6, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com