Method for preparing high-purity acarbose

An acarbose and high-purity technology is applied in the field of preparing high-purity acarbose by using membrane technology, and can solve the problems of low yield of acarbose active ingredients, large amount of resin used, high labor intensity and the like, and achieves the Conducive to pollution, reduced resin usage, and reduced labor intensity

Inactive Publication Date: 2003-04-30

ZHEJIANG DONGLI INDAL

View PDF3 Cites 20 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

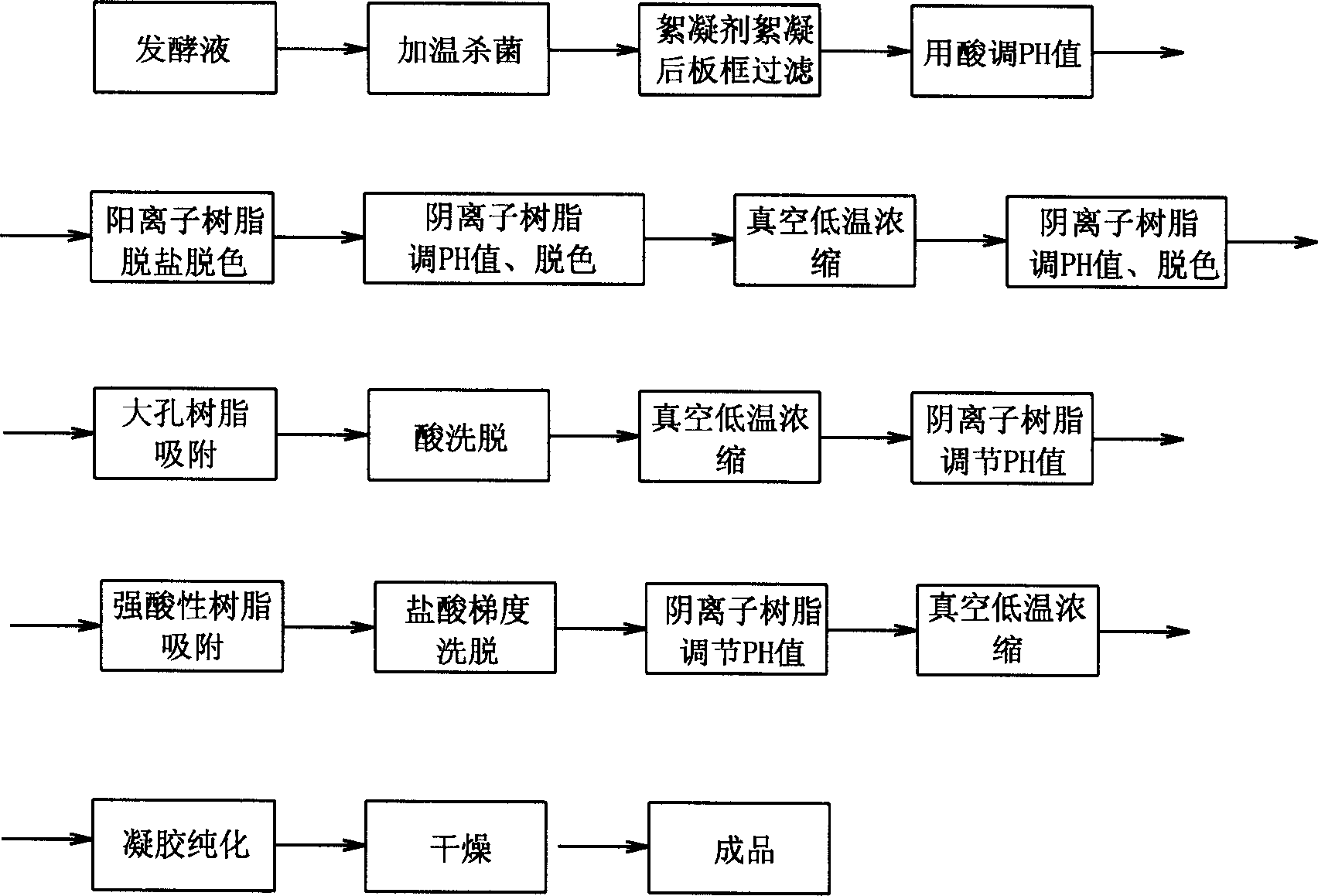

[0005] This method has the disadvantages of low yield of active ingredients of acarbose in the separation process, high cost of preparation method, high labor intensity, high energy consumption, large amount of resin used, and serious acid-base pollution.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0022] System parameters

Embodiment 2

[0024] System parameters

Embodiment 3

[0026] System parameters

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

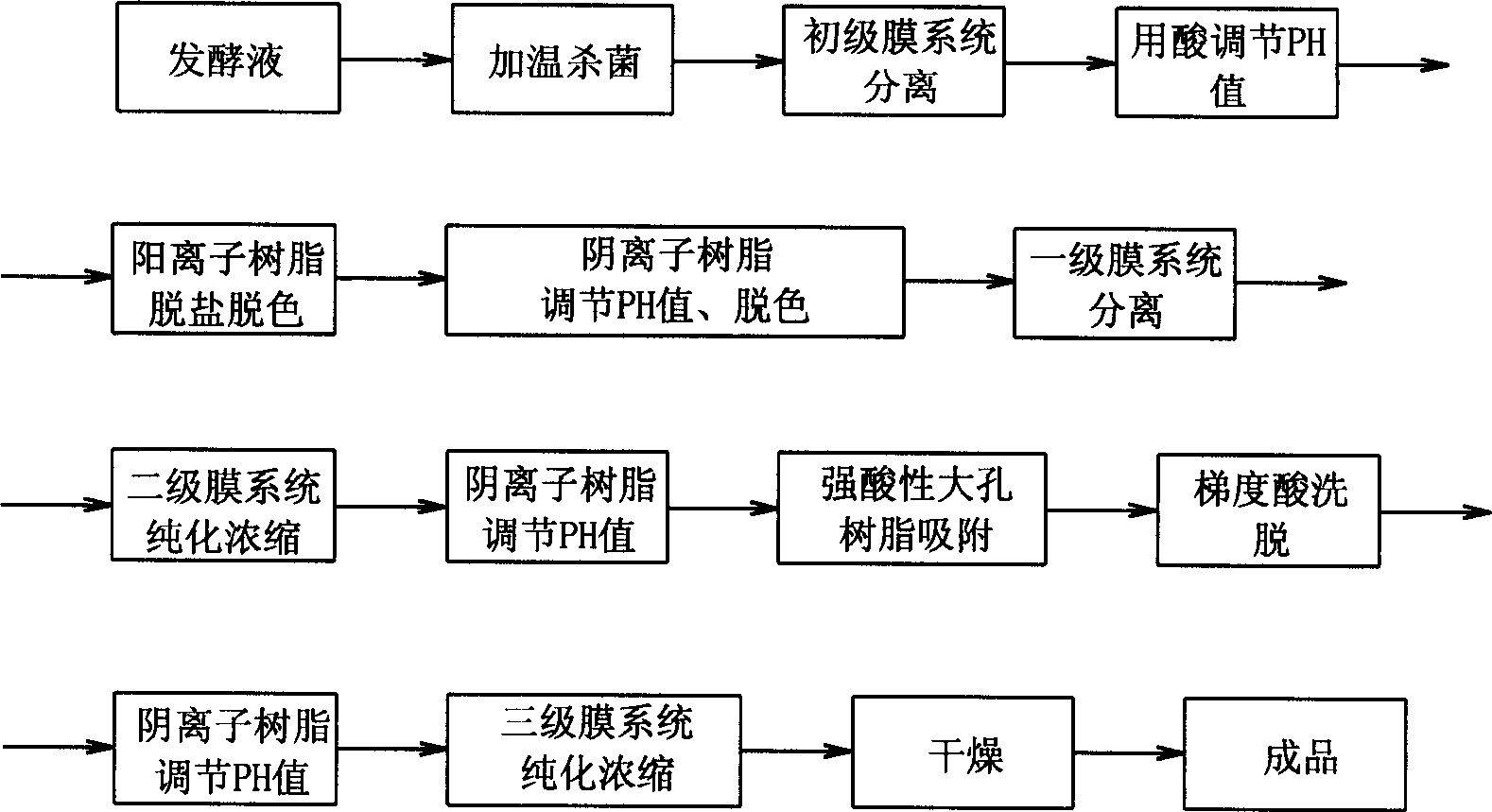

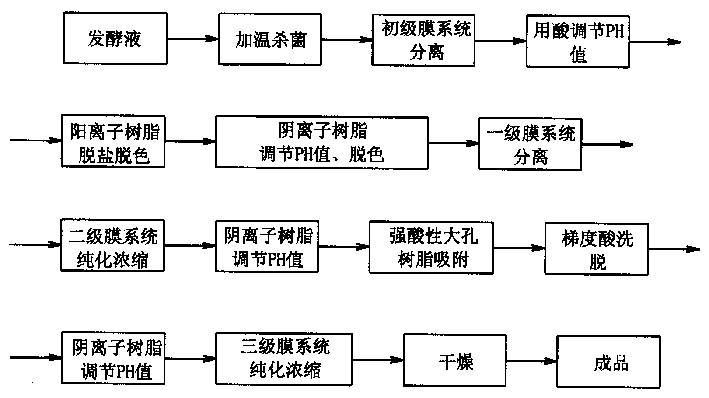

A process for preparing high-purity Acarbose includes such steps as heating the fermented Acarbose liquid for sterilizing, primary membrane separation, cooling, regulating pH value, desalting and decolouring, regulating pH value, stage-one membrane separation, stage-2 membrane purifying, concentrating, regulating pH value, macroreticular resin adsorption, pickling, collecting high-purity (98%) solution of Acarbose, regulating pH value, stage-3 membrane purifying, concentrating and drying. Its advantages are high extraction rate, less environmental pollution and low cost.

Description

technical field [0001] The invention relates to a method for preparing acarbose, in particular to a method for preparing high-purity acarbose using membrane technology. Background technique [0002] Acarbose (Acarbose) is a kind of α-glucosidase inhibitor, molecular weight is 650, can be used as the anti-diabetic drug of oral treatment type II diabetes, and trade name is Bai Sugar Ping. The active compound is produced by fermentation, and the produced strain is actinomycetes SE50 / 110 or its derivative mutant. Acarbose must be separated from the broth after fermentation to produce a pure product. [0003] The content of active compounds of acarbose in the fermentation broth is not high, about 1500 micrograms per milliliter, and the current separation and purification technology uses ion resins with different structures to adsorb and purify acarbose. For this reason, German patent specification No. 2347782, No. 2719912 and Chinese patent specification ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C07H1/06C07H3/08

Inventor 陈冠雄严阿根

Owner ZHEJIANG DONGLI INDAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com