Evaluation method for nano powder material light catalysis property

A nano-powder, photocatalytic technology, applied in the direction of chemical analysis using catalysis, can solve expensive, such as scanning tunneling microscope, atomic force microscope, laser detection atomic force microscope, low temperature scanning microscope, vacuum scanning tunneling One hundred thousand yuan or even several million yuan, can not be determined and other problems, to achieve the effect of fast analysis and testing, simple equipment, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

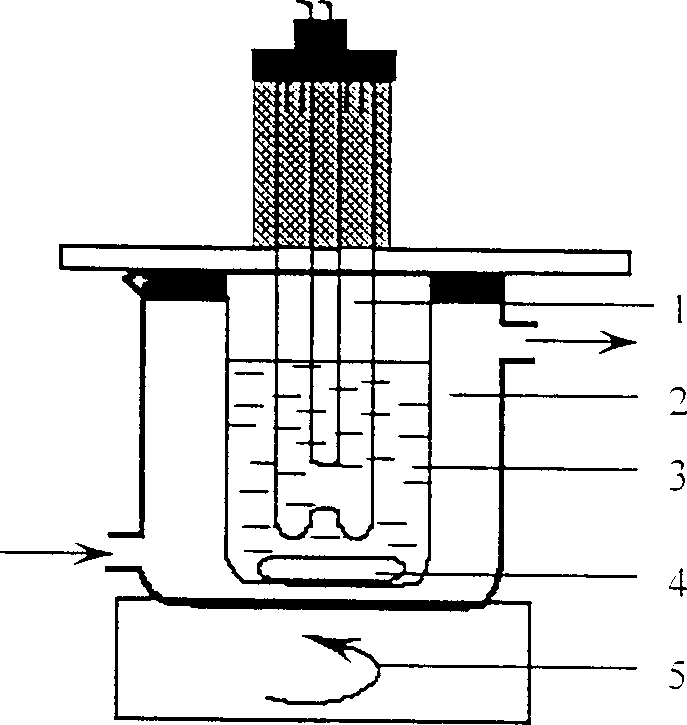

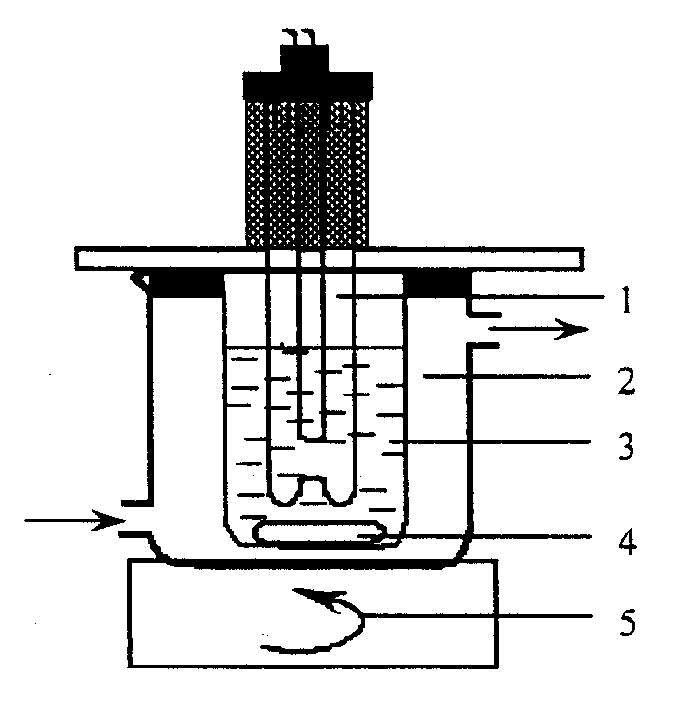

Method used

Image

Examples

Embodiment 1

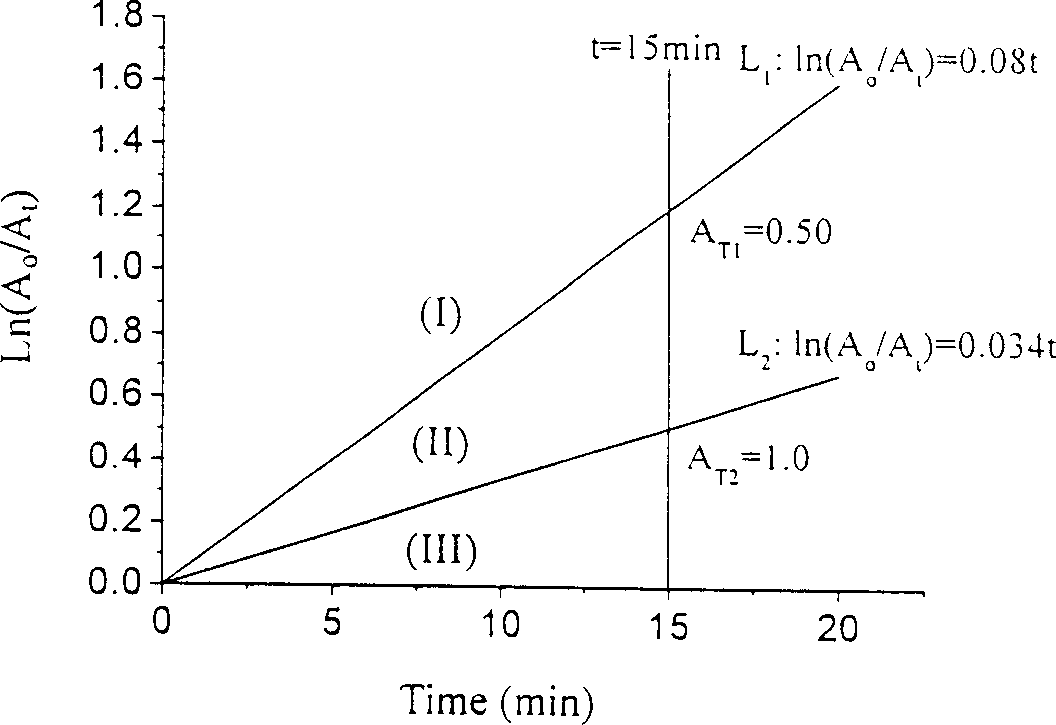

[0038] The nano powder material to be evaluated is P25 nano TiO produced by Germany Degussa company 2 Material. Its specific technical indicators are: particle size: 30nm; crystal form: 80% anatase phase, 20% rutile phase; preparation method: gas phase method. Utilize the photocatalytic performance evaluation method of the nano powder material provided by the present invention to carry out the photocatalytic performance evaluation, record the final absorbance A of the methyl orange solution at a wavelength of 470nm T 0.314, less than 0.5, the photocatalytic performance of the nano powder material is superior. It shows that the nano-powder material has good photocatalytic performance and can be used in the field of environmental optimization such as industrial sewage treatment, sterilization and disinfection.

Embodiment 2

[0040] The nano powder material to be evaluated is self-made HSD-2001 nano TiO 2 Sample after material treatment at 500°C for 3 hours. Utilize the photocatalytic performance evaluation method of the nano powder material provided by the present invention to carry out the photocatalytic performance evaluation, record the final absorbance A of the methyl orange solution at a wavelength of 470nm T It is 0.910, between 0.5 and 1.0, and the photocatalytic performance of the nanopowder material belongs to the passing grade.

Embodiment 3

[0042] The nano powder material to be evaluated is 101nm TiO specially used for coatings 2 . Utilize the photocatalytic performance evaluation method of the nano powder material provided by the present invention to carry out the photocatalytic performance evaluation, record the final absorbance A of the methyl orange solution at a wavelength of 470nm T is 1.161, and greater than 1.0, the photocatalytic performance of the nanopowder material is at a poor level, and the photocatalytic activity is relatively poor.

[0043] The above examples illustrate that the method for evaluating the photocatalytic performance of the nano-powder material provided by the present invention has various meanings: at first, utilizing the present invention and the evaluation criteria provided therefor, to regulate the nano-powder material market, effectively and effectively Secondly, from a specific aspect, the present invention and the standards provided by it can provide a specific basis for the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com