Control method for hydraulic pinch roll and controll apparatus thereof

A control device and control method technology, applied in rolling mill control devices, metal rolling, manufacturing tools, etc., can solve problems such as repeated unevenness of the end surface of the coil, poor coil shape, and poor coil coil shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

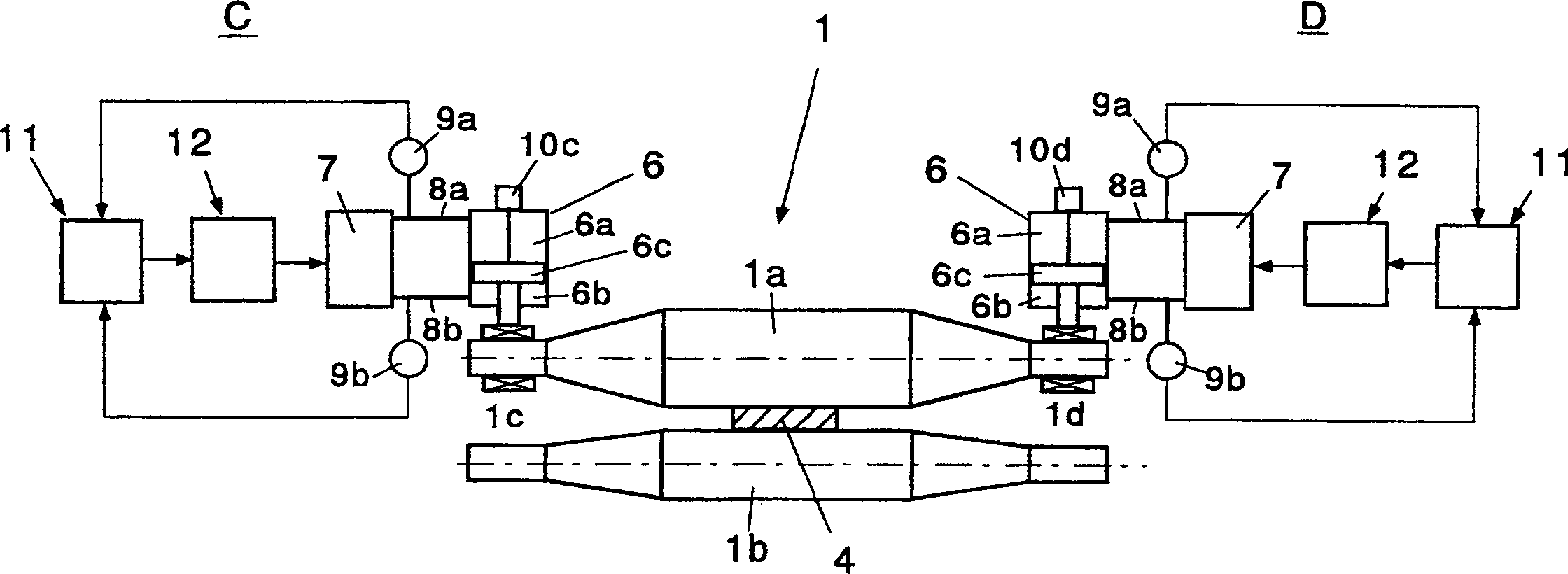

[0021] Figure 5 The overall configuration diagram showing the first embodiment of the pinch roller according to the present invention is shown, and the parts common to those in FIG. 2 are denoted by the same reference numerals, and overlapping descriptions are omitted.

[0022] In the apparatus of the present invention, the pressing force of the upper pinch roll 1a with respect to the steel strip 4 is controlled by the pressing force control devices C and D on the left and right, as in the conventional apparatus of FIG. 2 . That is, according to the pressure P of the cylinder head end 6a and the piston rod end 6b of the hydraulic cylinder 6 detected by the pressure detectors 9a and 9b provided in the middle of the pipes 8a and 8b a , P b , the pressing force F generated by the hydraulic cylinder 6 is calculated by the calculator 11, F=P a ×A h -P b ×A 1 (where, A h , A 1 Represents the area of the cylinder head end and the piston rod end of the piston 6c), which is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com