Connector and its mfg. method

A technology of connectors and connecting parts, applied in connection, fixed connection, printed circuit manufacturing, etc., can solve problems such as incomplete connection between terminals and electronic circuits, high total cost of manufacturing connectors, and complicated manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

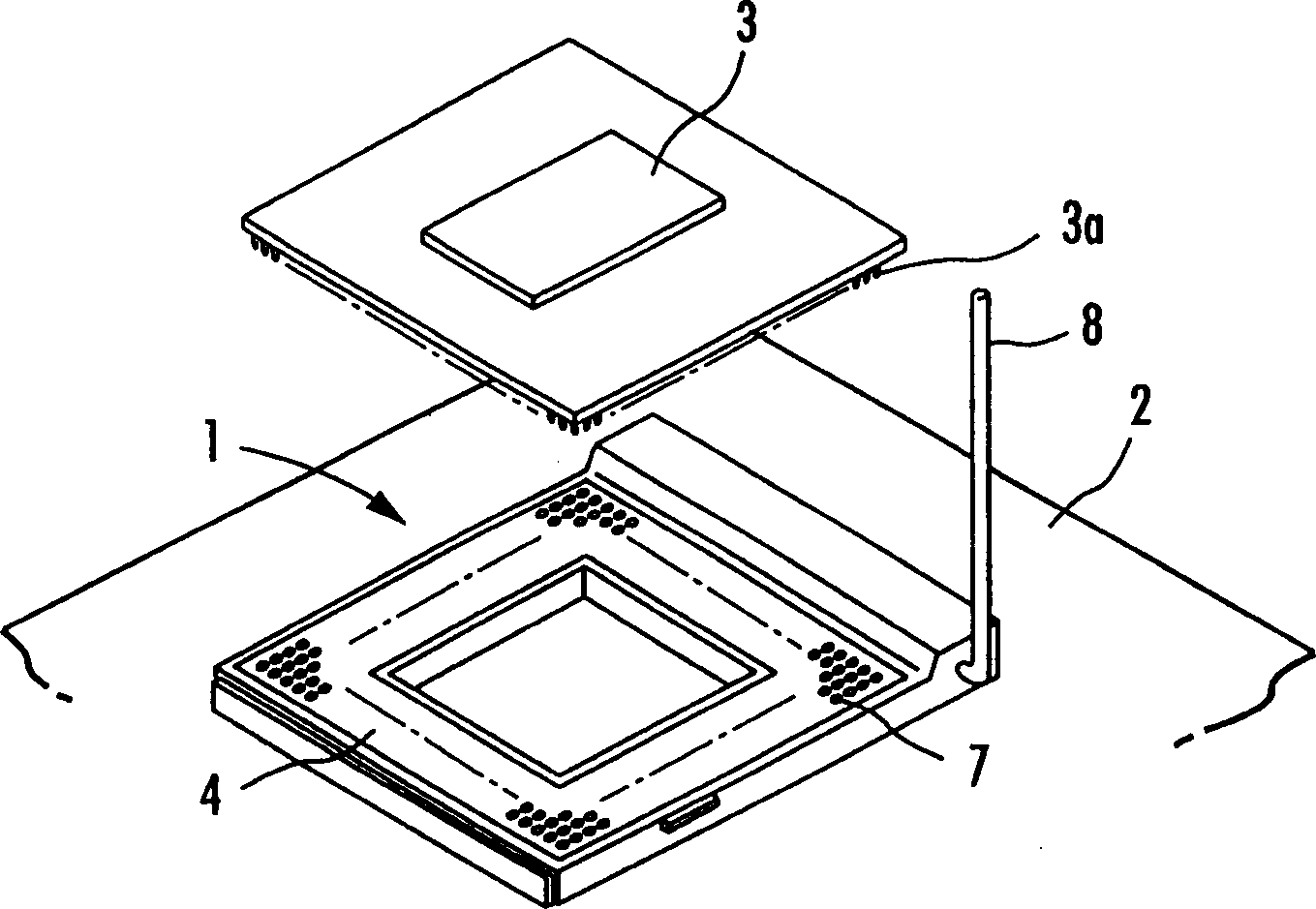

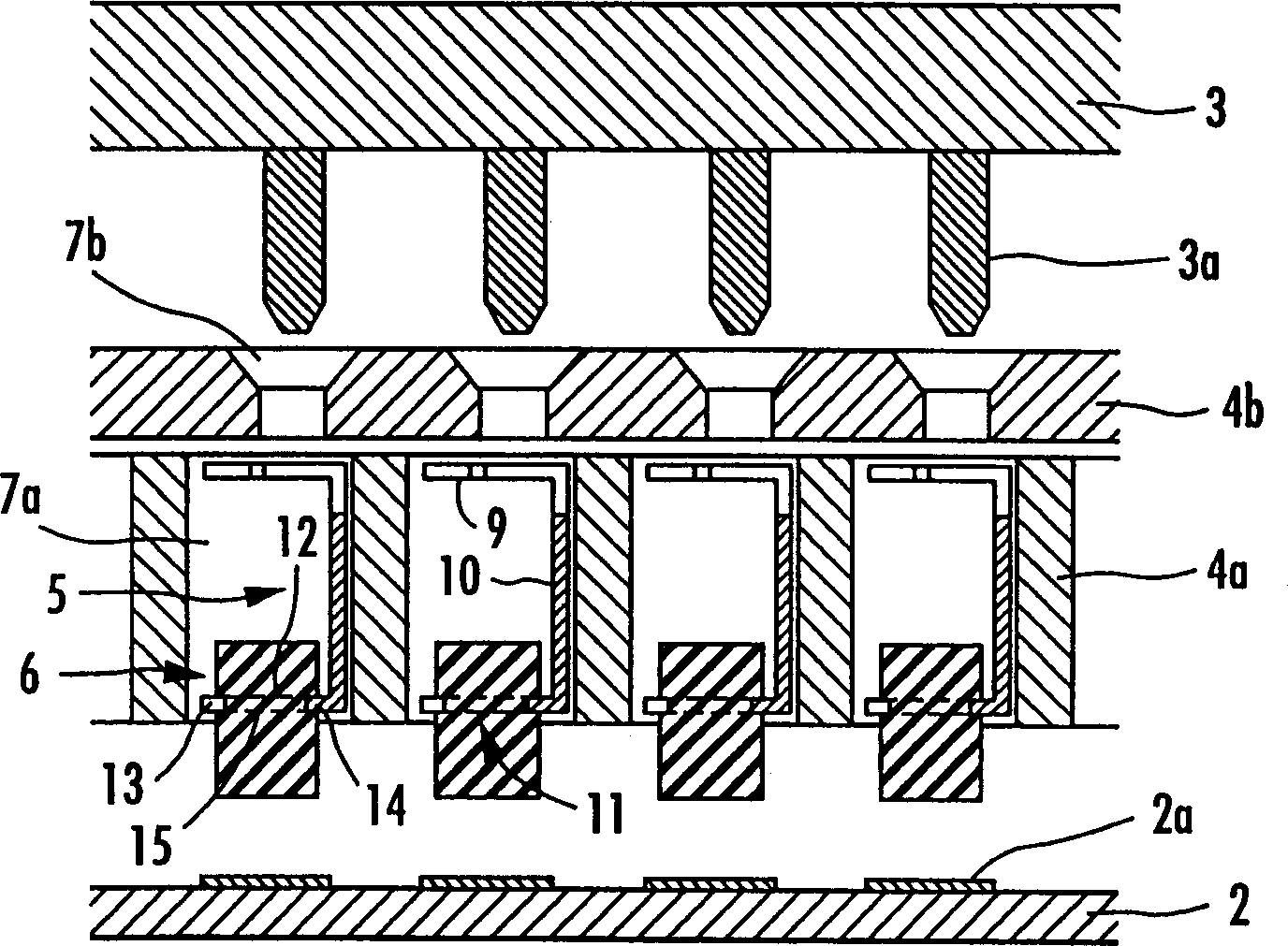

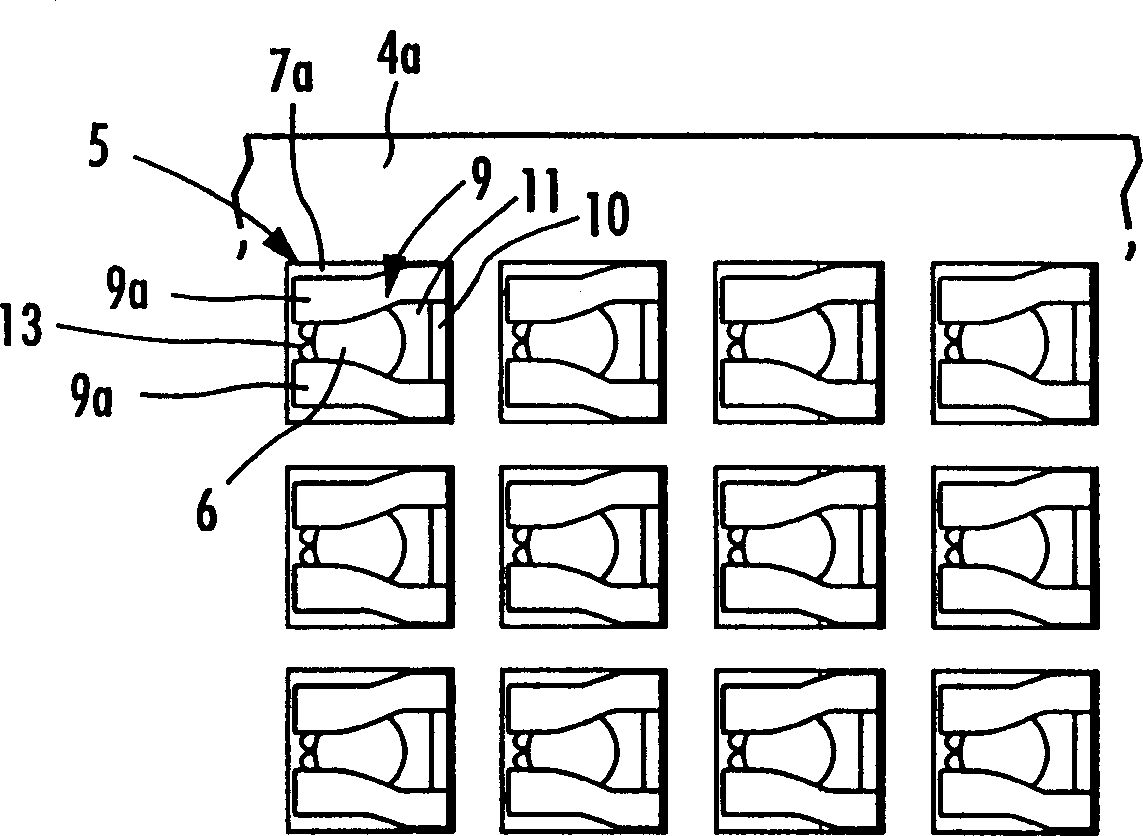

[0064] refer to Figure 1 to Figure 1 9. Describe a typical connector embodying the present invention. figure 1 is a schematic diagram of a typical connector embodying the invention, figure 2 is an enlarged fragmentary cross-sectional view of a connector according to a first embodiment of the present invention, image 3 is a partial plan view showing the internal state of the first embodiment, Figure 4 is a schematic diagram showing terminals of the connector according to the first embodiment, Figure 5a and 5b are schematic diagrams showing terminals of the connector according to the second embodiment, Figure 6a to 6c are schematic diagrams showing a method of fixing solder in a terminal, Figure 7 is a schematic diagram showing the process of improving coplanarity at the solder tip, Figure 8a to 8c are schematic diagrams showing connection states between terminals on the circuit board and electronic circuits according to this embodiment and a comparative example, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com