Contact structure having contact block

A technology of contact structure and contactor, which is applied in the direction of contact parts, connections, fixed connections, etc., and can solve problems such as contact pressure, contact resistance and bandwidth influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

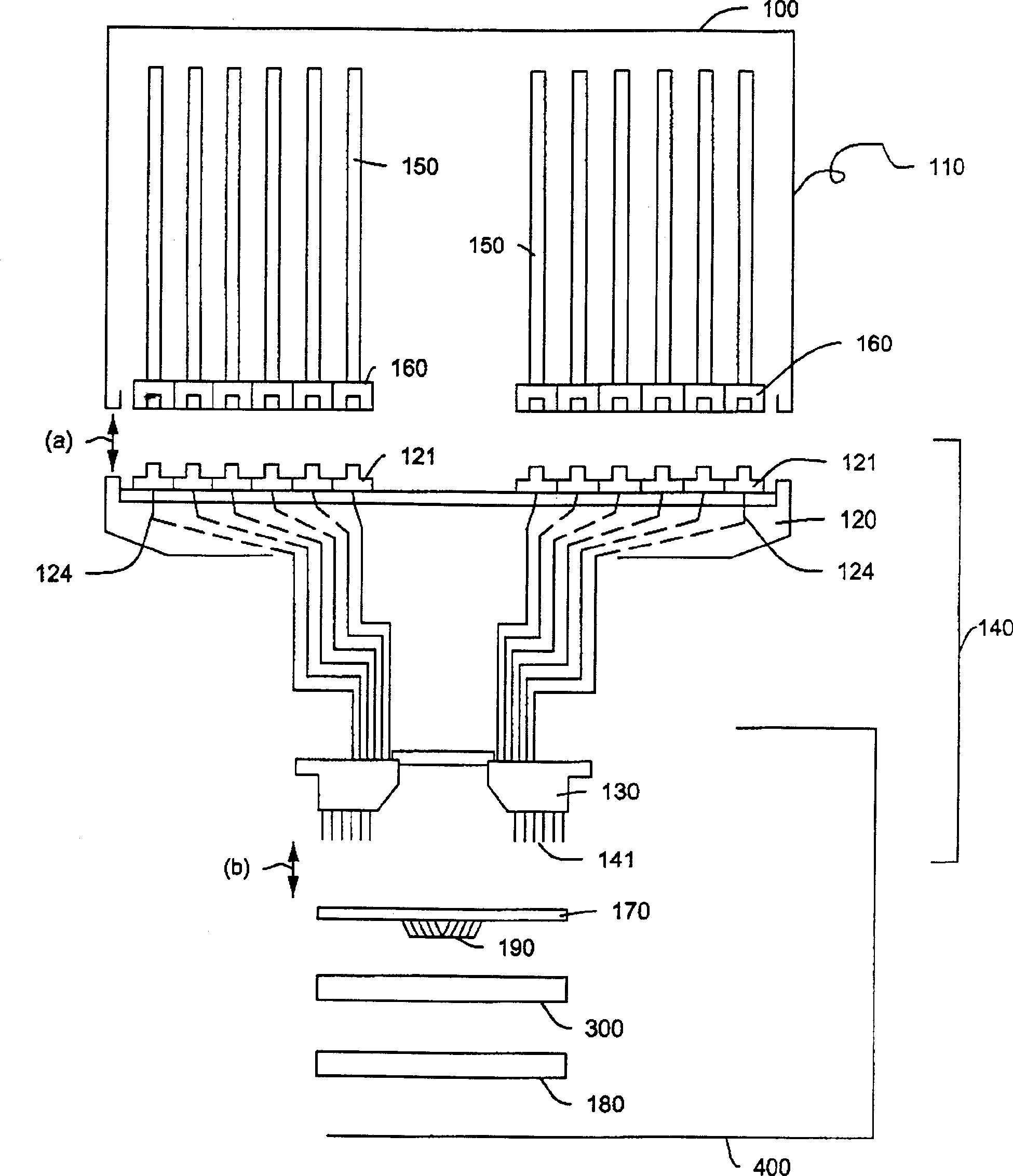

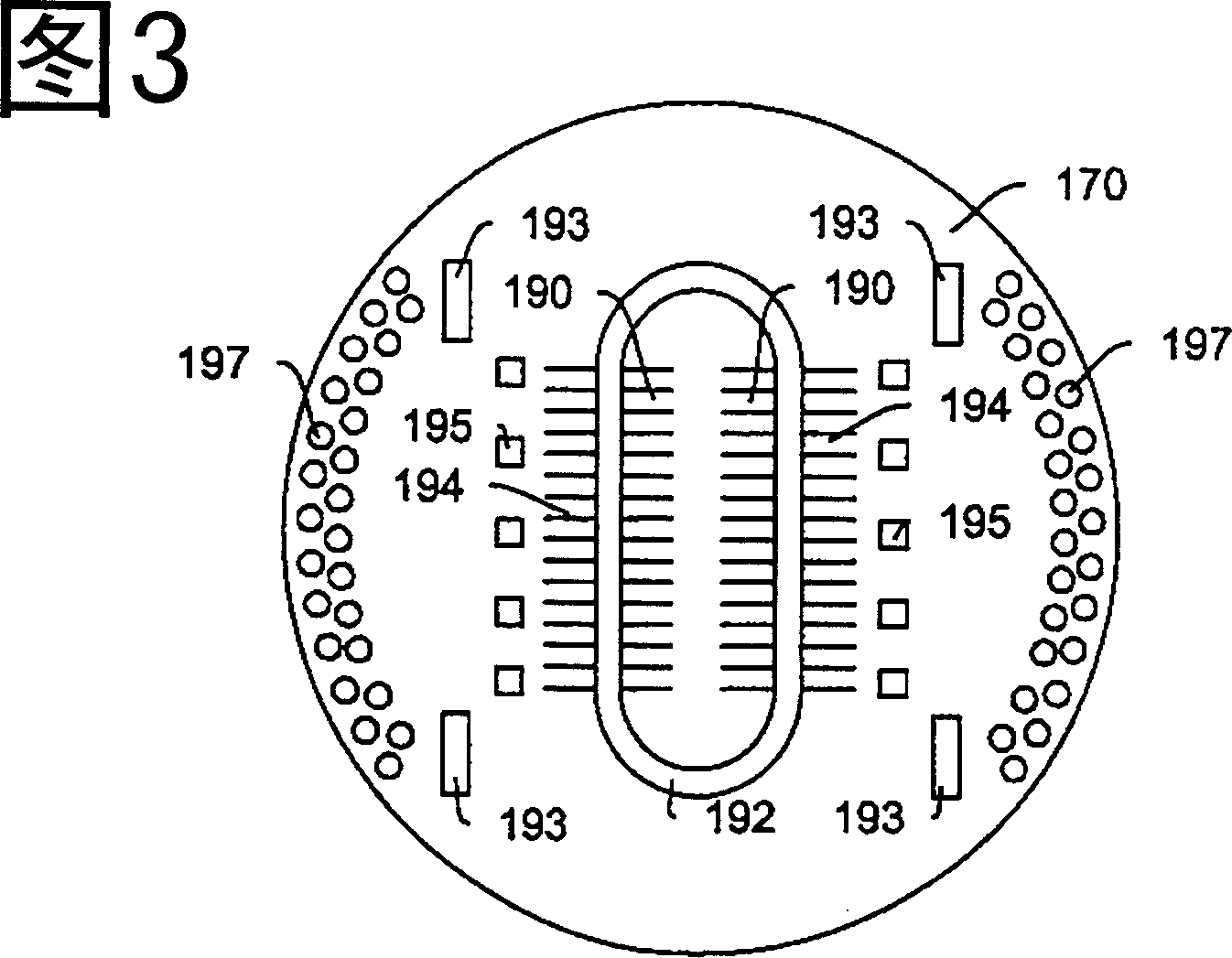

[0038] A first embodiment of the contact structure of the present invention is shown in Fig. 5 and Figure 6 Among them, it includes a plurality of plate-shaped contacts 30 as a whole, and the contactor is composed of a plurality of wires 35 , a dielectric layer 36 , a ground layer 37 and a plurality of contact bumps 31 fixed on the wires 35 . exist Figure 6 , the contactor 30 is fixed on the contact substrate 20 . The plate contact 30 is preferably formed by a tape automated bonding (TAB) technique used in the electronics industry. Tape Automated Attachment Process (TAB) is usually used to roll up semiconductor wafers when thinner housings are required. In the present invention, this TAB technique is used to create an impedance-matched contact structure to achieve higher frequency bandwidth.

[0039] When this TAB technique is used in the present invention, a set of contacts having a plurality of contacts mounted on a dielectric substrate further mounted on a ground plane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com