Operating load control for fuel cell power system in fuel cell vehicle

A fuel cell vehicle, fuel cell technology, applied in battery/fuel cell control devices, fuel cells, fuel cell additives, etc., can solve problems such as high cost and reduced fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

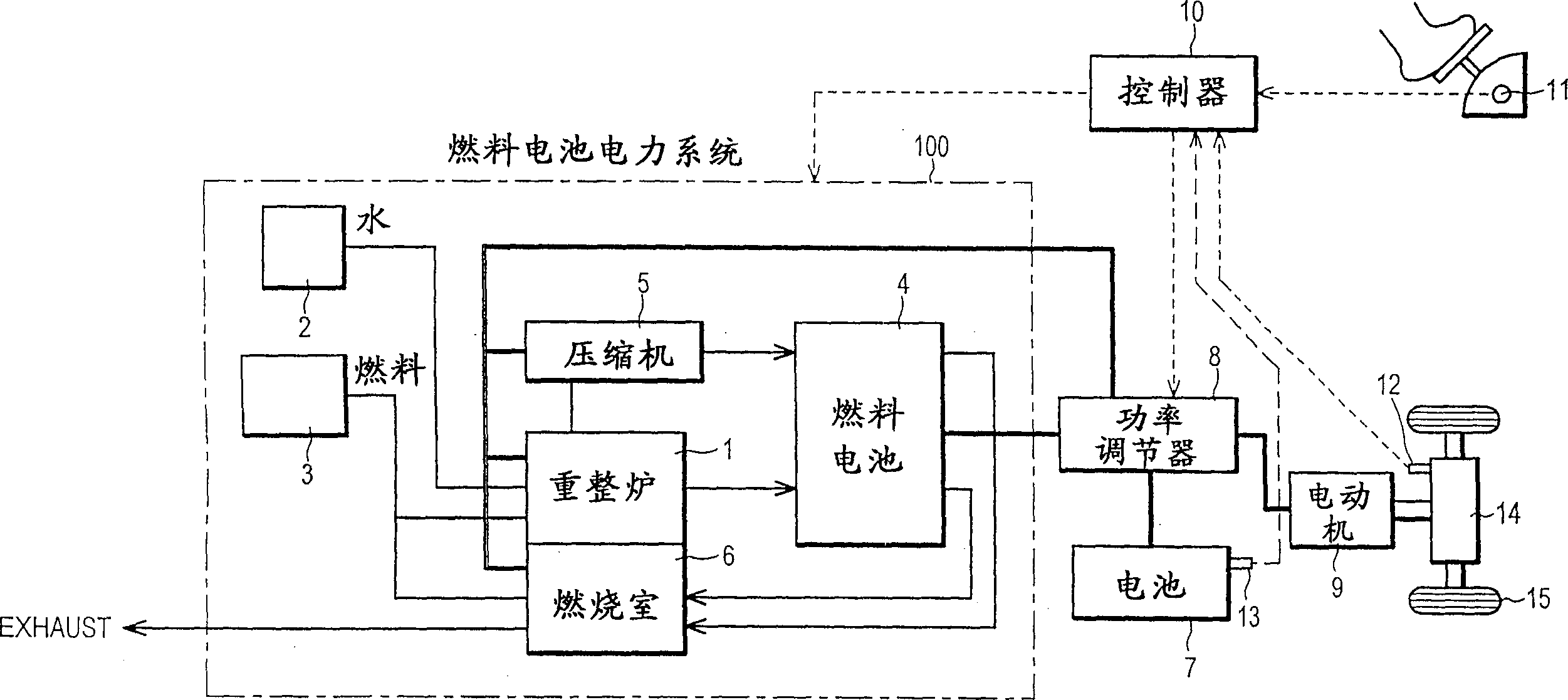

[0023] Refer to the attached figure 1 , figure 1 The structure of the fuel cell vehicle related to the present invention is shown. The fuel cell power system 100 enclosed by the dashed line in the figure includes: a reforming furnace 1, a water tank 2, a fuel tank 3, a fuel cell 4, and a compressor 5.

[0024] The reformer 1 is supplied with water and methanol from the water tank 2 and the fuel tank 3, and the reformer 1 generates a reformed gas containing hydrogen from the steam reforming. Steam reforming is an endothermic reaction. The reformed gas is supplied to the anode of the fuel cell 4. Hydrocarbon fuels other than methanol such as gasoline can also be used as fuel.

[0025] If the reforming catalyst injected into the reformer 1 does not reach the activation temperature, for example, when the system is just started, the air as the oxidant is supplied to the reformer 1 from the compressor 5, and the reforming caused by partial oxidation of methanol can also be performed. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com