Epoxy resin cloth coil and its making process

A technology of epoxy resin and voice coil, which is applied in the field of voice coil product manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

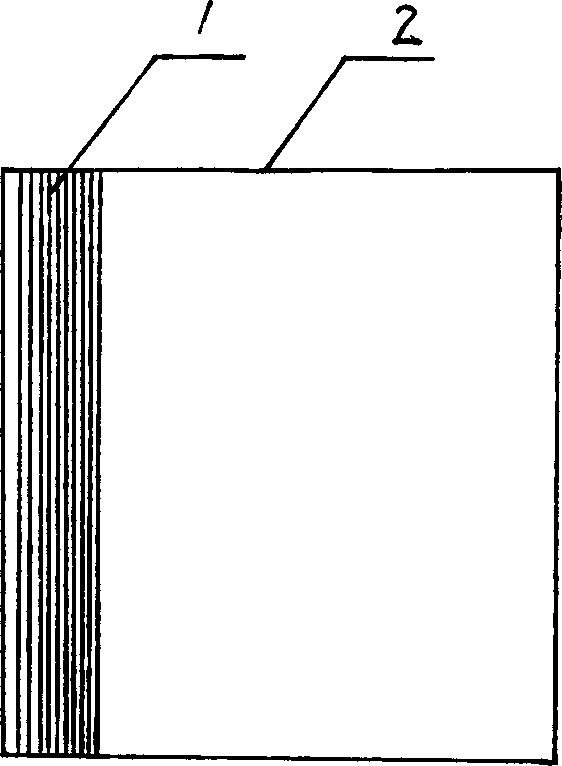

[0007] Embodiment 1: with reference to attached figure 1 . The epoxy resin cloth voice coil, the coil (1) is wound on the voice coil (2), and the voice coil (2) is a one-time molded epoxy resin cloth.

Embodiment 2

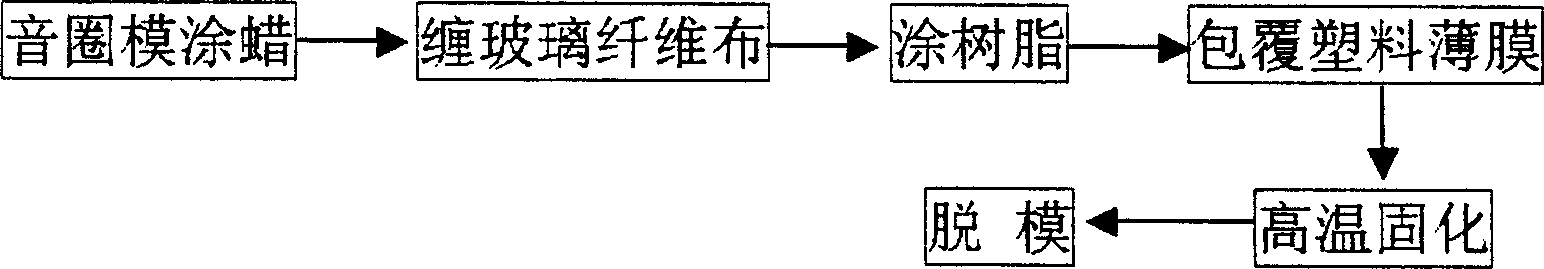

[0008] Embodiment 2: the preparation method of epoxy resin cloth voice coil, at first be coated with wax on the voice coil mold, then wind glass fiber cloth on the voice coil mold and be coated with resin, after plastic film is wrapped on it again , After curing at a high temperature of 160 ° C to 200 ° C and demolding once, the epoxy resin cloth voice coil is formed. Resin is coated between the glass fiber cloth and the glass fiber cloth.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com